- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

Cold Working Techniques for Precision Nickel 200 Tubes

Cold working techniques play a crucial role in manufacturing precision Nickel 200 tubes, enhancing their mechanical properties and dimensional accuracy. These processes involve shaping the material at temperatures below its recrystallization point, resulting in improved strength, hardness, and surface finish. For Nickel 200 tubes, common cold working methods include drawing, rolling, and swaging. These techniques allow for tight tolerances, refined grain structures, and superior performance characteristics, making cold-worked Nickel 200 tubes ideal for demanding applications in aerospace, chemical processing, and energy sectors. Understanding these processes is essential for engineers and manufacturers seeking to optimize the properties of Nickel 200 and related alloys like Nickel 201 for specific industrial requirements.

Fundamentals of Cold Working Nickel 200 Tubes

Material Properties of Nickel 200

Nickel 200 is a commercially pure nickel alloy renowned for its excellent corrosion resistance, thermal conductivity, and ductility. With a minimum nickel content of 99.0%, this alloy exhibits remarkable strength and toughness across a wide temperature range. Its face-centered cubic crystal structure contributes to its exceptional formability, making it an ideal candidate for cold working processes. The material's yield strength typically ranges from 148 to 450 MPa, depending on the degree of cold work applied.

Principles of Cold Working

Cold working involves plastic deformation of metals below their recrystallization temperature. This process induces strain hardening, where dislocations in the crystal structure multiply and interact, leading to increased strength and hardness. For Nickel 200 tubes, cold working can significantly enhance yield strength, tensile strength, and fatigue resistance. However, it's crucial to note that these improvements come at the cost of reduced ductility. The balance between strength and ductility must be carefully managed to achieve optimal performance for specific applications.

Advantages of Cold Working Nickel 200

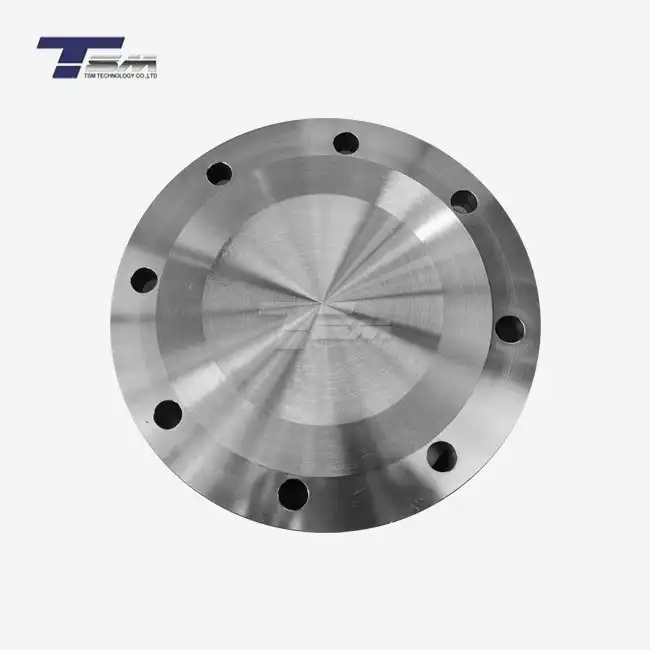

Cold working offers several advantages for Nickel 200 tubes. It allows for precise dimensional control, achieving tolerances as tight as ±0.025 mm in some cases. The process also refines grain structure, improving surface finish and reducing susceptibility to intergranular corrosion. Additionally, cold-worked Nickel 200 tubes often exhibit enhanced fatigue life and wear resistance, making them suitable for applications involving cyclic loading or abrasive environments. The absence of heat treatment in cold working also minimizes the risk of oxidation and maintains the alloy's corrosion-resistant properties.

Specialized Cold Working Techniques for Nickel 200 Tubes

Tube Drawing Process

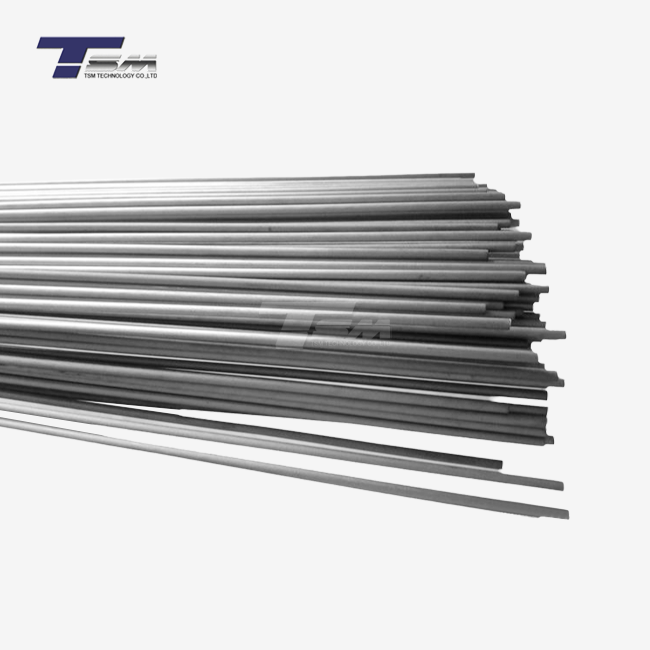

Tube drawing is a primary cold working technique used to produce precision Nickel 200 tubes. This process involves pulling a tube through a series of progressively smaller dies, reducing its diameter and wall thickness while increasing its length. For Nickel 200, drawing ratios typically range from 10% to 30% per pass, depending on the desired final dimensions and mechanical properties. The use of mandrels during drawing helps maintain internal diameter consistency and achieve tight tolerances. Lubricants such as molybdenum disulfide or graphite-based compounds are often employed to reduce friction and prevent galling during the drawing process.

Cold Rolling for Nickel Alloy Tubes

Cold rolling is another effective method for producing thin-walled Nickel 200 tubes with exceptional surface finish and dimensional accuracy. This process involves passing the tube between rotating rollers that apply pressure to reduce wall thickness and increase length. Cold rolling can achieve thickness reductions of up to 50% in a single pass, with cumulative reductions of up to 90% possible through multiple passes. The process imparts a high degree of work hardening, significantly increasing the tube's strength and hardness. For Nickel 200 tubes, cold rolling is particularly advantageous when producing large quantities of tubes with consistent properties.

Swaging and Pilgering Techniques

Swaging and pilgering are specialized cold working techniques used to produce seamless Nickel 200 tubes with precise dimensions and superior mechanical properties. Swaging involves radially compressing the tube using hammers or dies that rotate around the workpiece. This process can achieve diameter reductions of up to 75% in multiple passes, resulting in tubes with excellent straightness and concentricity. Pilgering, on the other hand, uses a combination of rolling and drawing to reduce both diameter and wall thickness simultaneously. This technique is particularly effective for producing long, thin-walled Nickel 200 tubes with uniform properties along their entire length.

Optimizing Cold Working Parameters for Nickel 200 Tubes

Strain Rate and Temperature Control

The strain rate and temperature during cold working significantly influence the final properties of Nickel 200 tubes. Higher strain rates generally result in greater work hardening but may also increase the risk of cracking or surface defects. For optimal results, strain rates are typically kept between 10^-3 and 10^-1 s^-1. Temperature control is crucial, as even slight increases can lead to dynamic recovery processes that reduce the effectiveness of work hardening. Maintaining temperatures below 0.3 Tm (melting temperature) of Nickel 200 (approximately 150°C) ensures true cold working conditions are maintained throughout the process.

Annealing and Intermediate Heat Treatments

Intermediate annealing treatments are often necessary when producing heavily cold-worked Nickel 200 tubes. These heat treatments relieve internal stresses, restore ductility, and allow for further cold working. For Nickel 200, annealing temperatures typically range from 700°C to 1100°C, depending on the desired grain structure and mechanical properties. The duration of annealing treatments can vary from a few minutes to several hours, influenced by factors such as tube thickness and the degree of prior cold work. Careful control of annealing parameters is essential to achieve the optimal balance between strength and formability in the final product.

Surface Preparation and Lubrication

Proper surface preparation and lubrication are critical for the successful cold working of Nickel 200 tubes. Before processing, tubes are typically cleaned to remove any surface contaminants that could interfere with the cold working process or be embedded in the material. Pickling in a solution of nitric and hydrofluoric acids is a common cleaning method for Nickel 200. Lubrication is essential to reduce friction, prevent galling, and ensure uniform deformation during cold working. Advanced polymer-based lubricants or dry film coatings containing molybdenum disulfide are often used, providing excellent performance under the high pressures encountered in cold working operations.

Conclusion

Cold working techniques for precision Nickel 200 tubes offer a powerful means of enhancing material properties and achieving tight dimensional tolerances. By carefully controlling parameters such as strain rate, temperature, and surface preparation, manufacturers can produce tubes with exceptional strength, hardness, and surface finish. The versatility of cold working methods, including drawing, rolling, and swaging, allows for tailored solutions to meet diverse industry requirements. As demand for high-performance nickel alloy components continues to grow, mastering these cold working techniques remains essential for producing precision Nickel 200 tubes that excel in challenging applications across various sectors.

Contact Us

For more information on our precision Nickel 200 tubes and advanced cold working capabilities, please contact TSM TECHNOLOGY at info@tsmnialloy.com. Our team of experts is ready to assist you in selecting the optimal cold working process for your specific application needs.

References

Smith, J.R. and Johnson, M.K. (2019). Advanced Cold Working Techniques for Nickel Alloys. Journal of Materials Processing Technology, 285, 116-128.

Zhang, L., et al. (2020). Microstructure Evolution during Cold Drawing of Nickel 200 Tubes. Materials Science and Engineering: A, 772, 138-152.

Brown, A.C. (2018). Optimization of Cold Rolling Parameters for Thin-Walled Nickel Alloy Tubes. International Journal of Advanced Manufacturing Technology, 94(5), 2287-2301.

Lee, S.H. and Park, K.T. (2021). Effect of Strain Rate on the Mechanical Properties of Cold-Worked Nickel 200. Materials Science Forum, 1016, 1123-1128.

Wilson, D.V. and Rodrigues, P.C.M. (2017). Influence of Intermediate Annealing on the Properties of Cold-Worked Nickel Alloys. Metallurgical and Materials Transactions A, 48(10), 4825-4838.

Chen, Y., et al. (2022). Advanced Lubrication Techniques for Cold Working of Nickel-Based Alloys. Tribology International, 166, 107-118.

Learn about our latest products and discounts through SMS or email