- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

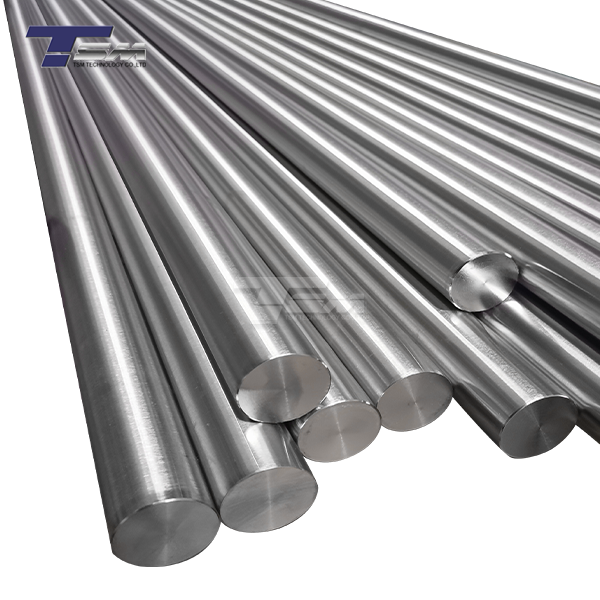

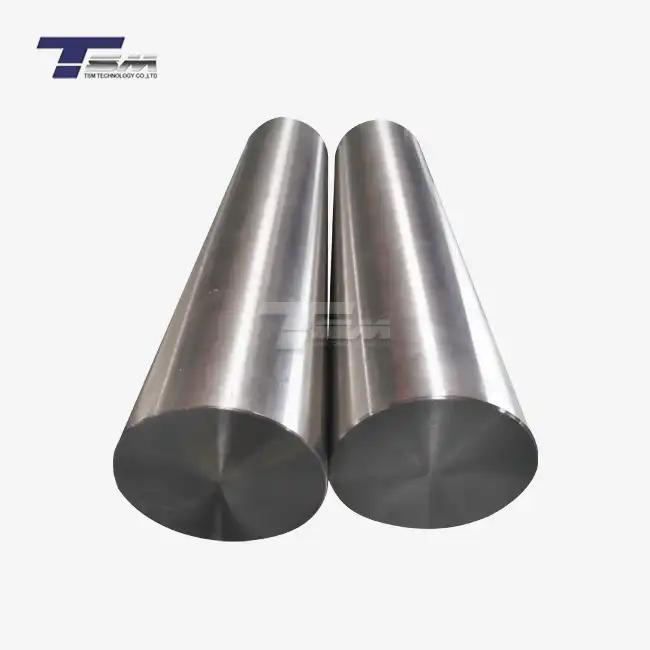

Nickel 201 Fasteners

Manufacturing Capacity: 300,000 pieces/month

Grade: Nickel 201 (UNS N02201)

Standard: ASTM F467, ASTM F594, JIS, DIN

Size :M1-M64 or Customized

Length:1mm-1990mm or Customized

Finish: Bright, Matte Finish, Polish Quality

EN10204 3.1/3.2,Third Party Inspection Report, etc

Customized Size and Processing: Supported

Delivery: 5–20 days

Note: Not for private person sale

Nickel 201 Fasteners Manufacturer & Supplier

Manufactured from commercially pure, low-carbon nickel, Nickel 201 Fasteners offer outstanding resistance to corrosive and caustic environments while maintaining stable mechanical performance at elevated temperatures. TSM Technology is a professional manufacturer and global supplier of Nickel 201 Fasteners, backed by over 15 years of experience in titanium and nickel alloy fastener production. Operating from a 60,000㎡ advanced manufacturing facility equipped with more than 100 precision machines, we specialize in delivering corrosion-resistant, high-purity Nickel 201 fasteners for precision-driven industries worldwide. Supported by five-axis machining centers, CNC lathes, thread rolling, and precision forming equipment, we are capable of producing fasteners from M1 to M64, including bolts, nuts, washers, and custom-engineered components. These products are widely used in aerospace, chemical processing, marine, electronics, and industrial equipment, where material purity, dimensional accuracy, and long-term reliability are essential.

Nickel 201 Fasteners Supply Type

Including hexagonal bolts, nuts, flat/spring washers, hexagon socket screws, studs and U-bolts, etc., in accordance with ASTM F467/F468 standards. Specifications cover M2.5-M64 threads, Class 50 to Class 2500 pressure levels, and support customization of non-standard special-shaped parts.

|

Incoloy 201(N02201/2.4060/Nickel201) |

|||||||||||

|

Brief introduction |

Nickel 201 is a pure commercial nickel with extremely low carbon content and has been approved for use in high temperature environments up to 1230°C. |

||||||||||

|

Chemical Composition |

% |

Ni |

Fe |

C |

Mn |

S |

Si |

Cu |

|||

|

min |

Remaining amount |

|

|

|

|

|

|

||||

|

max |

Remaining amount |

0.4 |

0.02 |

0.35 |

0.01 |

0.35 |

0.25 |

||||

|

Physical Characteristics |

Density |

8.89g/cm³ |

|||||||||

|

Melting point |

1440℃ |

||||||||||

|

Minimum mechanical properties of alloys at room temperature |

Alloy state |

tensile strength Rm N/mm² |

Yield Strength RP0.2 N/mm² |

Elonga A5% |

|||||||

|

Inconel 201 |

60-85 |

15-45 |

35-55 |

||||||||

Material Characteristics

Superior Corrosion Resistance – Ideal for highly corrosive environments, including acidic and alkaline applications.

High Thermal & Electrical Conductivity – Excellent performance in electronic and heat-exchanging applications.

Non-Magnetic & Ductile – Ensures ease of fabrication and welding.

Exceptional Performance at High Temperatures – Low carbon content prevents embrittlement.

Applications of Nickel 201 Fasteners

Nickel 201 Fasteners are widely used across industries, including:

Aerospace – High-temperature and corrosion-resistant components.

Chemical Processing – Equipment used in highly acidic or alkaline environments.

Marine & Offshore – Components exposed to saltwater and harsh marine conditions.

Electronics – Conductive fasteners for electrical applications.

Energy Sector – Used in nuclear and renewable energy systems.

Why choose us?

We are looking for partners around the world to expand our business.

Customized production

size, shape, process customization on demand, support reverse development of drawings/samples.

Specification supply

thread M2.5-M64, pressure level Class 50 to Class 2500.

Full product category coverage

hexagonal bolts, nuts, studs, U-bolts, etc., supports non-standard customization

Fast proofing service

provides samples in 5-7 days to accelerate the project verification cycle.

Heat treatment optimization

solution treatment, annealing, aging treatment, and precise matching of performance requirements.

Industry Certifications

EN10204 3.1/3.2, Third-Party Inspection Reports available.

Package

FAQ

Q: What sizes are available for Nickel 201 Fasteners?

A: Standard sizes range from M2.5 to M32, with custom sizes available upon request.

Q: What is the typical delivery time?

A: Delivery is approximately 10-25 days, depending on order specifications.

Q: Do you provide test reports and certifications?

A: Yes, we provide EN10204 3.1/3.2 certificates and third-party inspection reports.

Q: What are the payment terms?

A: We accept T/T, L/C, PayPal, Western Union, or other preferred methods.

Contact Us

For high-quality Nickel 201 Fasteners, reach out to us today!

Email: info@tsmnialloy.com

Learn about our latest products and discounts through SMS or email

Learn about our latest products and discounts through SMS or email

_1739070074580.webp)