- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

Nickel alloys in the power industry

Nickel alloys are widely used in the power industry due to their various advantages. Its excellent properties contribute to the reliable and efficient operation of various power generation systems, making it an ideal material for power generation and distribution systems.

Nickel alloys are widely used in power plants due to their excellent corrosion resistance, oxidation resistance, and high-temperature strength. In fossil fuel power plants, nickel alloys are used in components such as heat exchangers, valves, and pumps. These components work in harsh environments and must be able to withstand corrosion and erosion caused by high-temperature and high-pressure steam.

Renewable energy sources such as wind turbines and solar panels also rely heavily on nickel alloys. These alloys are used in the construction of wind turbines, including rotor blades and gearboxes, which require strength and durability to cope with the extreme conditions of wind power generation. Nickel alloys are also required in the construction of solar panels, which are used to connect solar cells and create electrical pathways.

Power Industry

Commonly Used Nickel Alloy Grades & Product Forms

| Product Form |

Common Grades |

Typical Power Industry Applications |

|---|---|---|

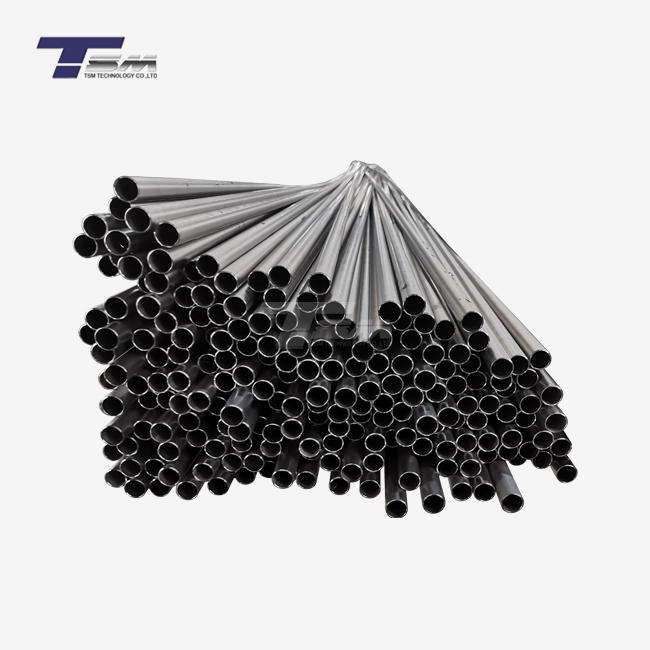

| Tube / Pipe |

Inconel 600 |

Boiler tubes, steam generator tubing |

|

Inconel 690 |

Nuclear steam generators | |

|

Incoloy 800 / 800H |

Superheaters, reheaters | |

| Plate / Sheet |

Inconel 625 |

Flue gas systems, FGD equipment |

|

Incoloy 825 |

Wet corrosion zones | |

| Bar / Rod |

Inconel 718 |

High-temperature bolts, pressure parts |

| Fasteners |

A286 |

Turbine and pressure equipment |

Contact Us

For high-quality products and expert technical support, contact us today:

Email: info@tsmnialloy.com

Learn about our latest products and discounts through SMS or email