- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

Hastelloy Pipe Fittings

Supply Ability: 200 Tons/month

Grade: Hastelloy C22 / C276 / B2

Standard: ASTM, JIS, AISI, GB, DIN, EN

Type: Elbow, Tee, Reducer, Stub End, Cap, Cross

Size: 1/2” to 24” (DN15–DN600)

Wall Thickness: SCH10 to SCH160

Form: Seamless / Welded Pipe Fittings

Finish: Bright, Matte Finish, Polish Quality

Customization and processing supported

Material Certification: MTC and SGS test reports available

Provide Free Sample

Not for Private Person Sale

Hastelloy Pipe Fittings - Premium Corrosion-Resistant Solutions

When you need reliable pipe connections in highly corrosive environments, Hastelloy Pipe Fittings deliver unmatched performance. These premium nickel-molybdenum alloy components provide exceptional resistance to aggressive chemicals and extreme temperatures. At TSM Technology, we manufacture high-quality products that meet strict industry standards, ensuring secure connections and structural integrity in chemical processing and marine applications.

What are Hastelloy Pipe Fittings?

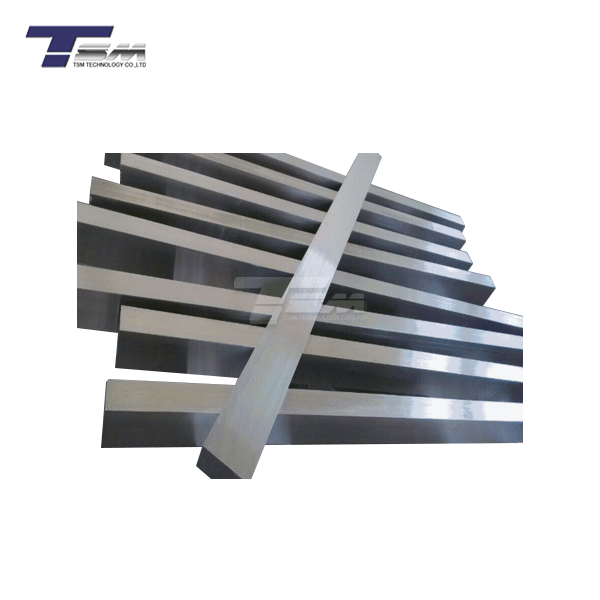

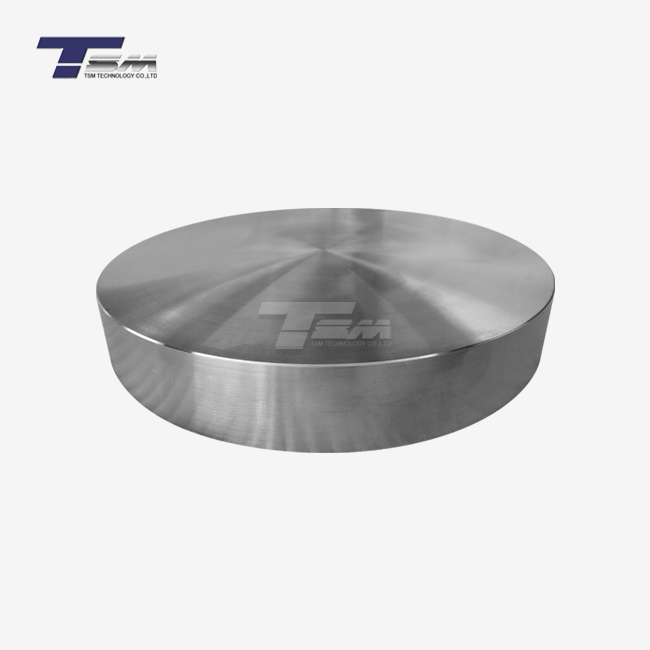

The items are specialized interfacing components made from nickel-molybdenum superalloys. These fittings connect pipe areas in frameworks exposed to corrosive chemicals, high temperatures, and forceful conditions. They stand up to setting, hole erosion, and stress-cracking. Our fittings incorporate elbows, tees, reducers, caps, and crosses.

Specification

| Parameter | Details |

|---|---|

| Grade | Hastelloy C22, C276, B2 |

| Size Range | 1/2" to 24" (DN15–DN600) |

| Wall Thickness | SCH10 to SCH160 |

| Type | Elbow, Tee, Reducer, Stub End, Cap, Cross |

| Form | Seamless / Welded |

| Standard | ASTM, JIS, AISI, GB, DIN, EN |

| Finish | Bright, Matte, Polish |

Physical and Chemical Properties

| Property | Value |

|---|---|

| Density | 8.69 g/cm³ |

| Melting Point | 1370°C (2500°F) |

| Tensile Strength | 690 MPa (100 ksi) |

| Yield Strength | 283 MPa (41 ksi) |

| Elongation | 40% min |

| Hardness | ≤ 22 HRC |

| Operating Temperature | Up to 650°C (1200°F) |

Product Standards

Our Hastelloy pipe fittings comply with international standards including ASTM B366 and UNS N10276. These standards ensure consistent quality, dimensional accuracy, and performance reliability. We adhere to ISO 9001, AS9100D, and AS9120 certification standards. All products meet ASME and EN specifications for industrial applications.

Features

- Exceptional Erosion Resistance: Extraordinary security against acids, chlorides, and oxidizing chemicals

- High Temperature Soundness: Keeps up quality and astuteness at elevated temperatures up to 650°C

- Superior Weldability: Simple joining with standard welding techniques

- Excellent Formability: Can be molded without compromising fabric properties

- Long Benefit Life: Diminished upkeep costs through expanded durability

- Versatile Setups: Accessible in different fitting sorts and sizes

Application

The product serves critical roles across demanding industries:

- Chemical Handling: Reactor frameworks, refining columns, warm exchangers

- Petrochemical Industry: Refineries, gas handling plants, catalyst systems

- Power Era: Steam frameworks, condensers, cooling circuits

- Marine Applications: Seawater frameworks, seaward platforms

- Pharmaceutical: Clean handling situations, sterile connections

- Pulp & Paper: Dying frameworks, chemical recuperation processes

Production and Processing Technology

TSM Innovation utilizes progressed fabricating methods for prevalent fitting quality. We utilize exactness manufacturing, machining, and shaping forms. Our 50,000㎡ office houses over 100 exactness machines. Hot shaping guarantees ideal grain structure and mechanical properties. Computer-controlled machining ensures dimensional precision and surface wrap up quality.

What is the production process of the product?

- Raw Fabric Choice: High-purity Hastelloy combination sourcing and verification

- Melting & Manufacturing: Controlled environment softening and exactness forging

- Heat Treatment: Arrangement toughening for ideal erosion resistance

- Machining: CNC accuracy machining to correct specifications

- Forming: Hot or cold shaping into required fitting configurations

- Surface Treatment: Cleaning, passivation, and wrapping up processes

- Quality Testing: Comprehensive assessment and execution verification

- Packaging: Defensive bundling for secure transportation

Quality Inspection

Every fitting undergoes rigorous testing procedures:

- Dimensional Verification: Precise measurement against specifications

- Ultrasonic Testing: Internal defect detection

- Radiographic Testing: Weld integrity examination

- Hydrostatic Testing: Pressure resistance validation

- Corrosion Testing: Chemical resistance verification

- Material Certification: MTC and SGS test reports provided

Why choose TSM Technology?

TSM Innovation stands out as your trusted accomplice for premium combination arrangements, including Hastelloy Pipe Fittings. Our 14+ years of involvement and trades to 70+ nations illustrate proven unwavering reliability. We keep up AS9100D certification for aerospace-grade quality standards. Our supply chain guarantees reliable execution, quick response, technical consultation, and after-sales support for your satisfaction.

Factory

Our present day 50,000㎡ square foot fabricating office highlights 3 industrial facilities with 8 generation lines. Progressed hardware incorporates exactness manufacturing hammers, CNC machining centers, and heat treatment heaters. Month-to-month generation capacity comes to 200 tons. Strict natural controls keep up ideal working conditions for prevalent item quality.

Package and Shipping

We give secure bunding utilizing defensive materials and moisture barriers. Standard bundling incorporates wooden cases for universal shipping. Express conveyance choices are available for critical requirements. Our Hong Kong coordination center guarantees effective worldwide dispersion. Full traceability documentation goes with each shipment.

FAQ

Q: What grades of Hastelloy do you offer for pipe fittings?

A: We make fittings in Hastelloy C22, C276, and B2 grades to meet diverse application requirements.

Q: Can you give custom-sized fittings for particular applications?

A: Yes, we offer customization services for non-standard sizes and arrangements based on your specifications.

Q: What certifications does your item have?

A: Our fittings comply with ASTM B366, UNS N10276, and other worldwide measures with full fabric certification.

Q: How do you guarantee the quality of your pipe fittings?

A: We conduct comprehensive testing counting ultrasonic, radiographic, and hydrostatic testing for each batch.

Q: What is the normal conveyance time for the product?

A: Standard conveyance ranges from 2-4 weeks depending on the estimate, amount, and customization necessities.

Contact Us

Ready to discuss your Hastelloy Pipe Fittings requirements? Our technical team is here to help you select the right solution for your application. Contact us today for expert consultation, detailed quotations, and free samples.

Email: info@tsmnialloy.com

Trust TSM Technology for your critical pipe fitting needs. We deliver quality, reliability, and performance in every product.

Learn about our latest products and discounts through SMS or email

Learn about our latest products and discounts through SMS or email