- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

Inconel X-750 Forgings

Supply Ability: 1000 Tons/year

Grade: Inconel X-750 (UNS No. N07750)

Standard: ASTM, JIS, AISI, GB, DIN, EN

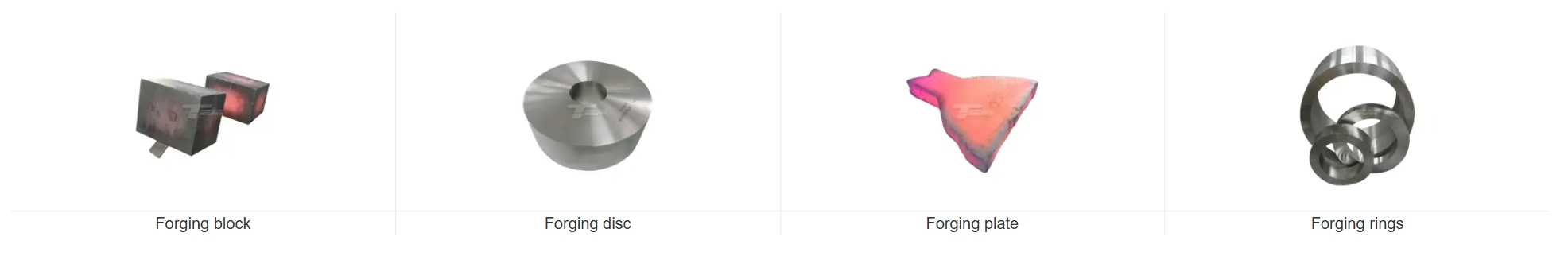

Type: Round, Square, Ring, Block, Custom Shapes

Size: Dia. 20 mm to 800 mm

Weight: Up to 2000 kg per piece

Form: Open Die, Closed Die Forging

Customization and processing supported

Material Certification: MTC and SGS test reports available

Delivery Time: Usually about 10-25 days

Provide Free Sample

Inconel X-750 Forgings – High-Performance Solutions by TSM Technology

Inconel X-750 Forgings from TSM Technology are high-performance nickel-chromium alloy components engineered for extreme high-temperature and corrosive environments. As a precipitation-hardenable superalloy, Inconel X-750 offers outstanding strength, oxidation resistance, and structural stability at temperatures up to 2,000°F (1,093°C), making it ideal for gas turbines, jet engines, nuclear systems, and other critical applications.

Founded in 2011, TSM Technology is a globally recognized supplier of specialty metal materials. Based in Shaanxi, China, we operate three factories with over 60,000㎡ of modern production facilities, eight production lines, and more than 100 advanced machines, including VAR furnaces and 2,500-ton forging presses. With an annual capacity of 1,200 tons, we deliver Inconel X-750 forgings through a fully integrated process—from raw material melting to precision forging and finishing. Backed by independent R&D capabilities, internationally certified quality systems, and exports to over 50 countries, TSM ensures reliable, high-performance Inconel X-750 forgings that meet the demanding requirements of aerospace, energy, medical, and industrial sectors worldwide.

Specifications

| Parameter | Details |

|---|---|

| Grade | Inconel X-750 (UNS N07750) |

| Standard | ASTM B637, ASTM, JIS, AISI, GB, DIN, EN |

| Form | Open Die Forging, Closed Die Forging |

| Shape | Round, Square, Ring, Block, Custom Shapes |

| Size Range | Diameter: 20 mm to 800 mm |

| Weight | Up to 2000 kg per piece |

| Surface Finish | Hot Forged, Machined, Polished (as required) |

| Customization | Available with full machining support |

Physical and Chemical Properties

| Property | Value |

|---|---|

| Density | 8.28 g/cm³ |

| Melting Point | 1393-1425°C (2540-2600°F) |

| Tensile Strength | ≥1240 MPa |

| Yield Strength | ≥827 MPa |

| Elongation | ≥15% |

| Hardness | ≤363 HB |

| Nickel (Ni) | 70% min |

| Chromium (Cr) | 14.0-17.0% |

| Iron (Fe) | 5.0-9.0% |

| Titanium (Ti) | 2.25-2.75% |

| Aluminum (Al) | 0.40-1.00% |

| Niobium (Nb) | 0.70-1.20% |

Product Standards

Our forged components strictly comply with international standards including ASTM B637 and UNS N07750 specifications. We also meet requirements outlined in JIS, AISI, GB, DIN, and EN standards. Each piece comes with complete material traceability documentation including Material Test Certificates (MTC) and SGS test reports upon request.

What are the Features of Inconel X-750 Forgings?

You'll benefit from several outstanding characteristics:

- Superior High-Temperature Strength: Maintains mechanical properties at temperatures up to 1,093°C

- Excellent Oxidation Resistance: Forms protective oxide layers preventing material degradation

- Outstanding Creep-Rupture Strength: Resists deformation under prolonged stress at elevated temperatures

- Thermal Fatigue Resistance: Withstands repeated heating and cooling cycles without cracking

- Good Formability: Can be hot-worked and shaped to meet your specific design requirements

- Weldability: Suitable for various welding processes when proper techniques are applied

- Carburization Resistance: Prevents carbon absorption in high-temperature environments

Application

Inconel X-750 Forgings serve critical roles across demanding industries:

Aviation Industry: Turbine edges, motor components, debilitate frameworks, pushed reversers, and afterburner parts where unwavering quality is non-negotiable.

Power Era: Gas turbine components, steam turbine parts, and atomic reactor internals requiring persistent high-temperature operation.

Petrochemical Handling: Warm exchanger components, heater installations, and weight vessel parts uncovered to destructive gasses at hoisted temperatures.

Industrial Gear: High-temperature latches, springs, and auxiliary components in heaters and heat-treating equipment.

Marine Applications: Components requiring both erosion resistance and high-temperature capability in impetus systems.

Production and Processing Technology

Our fabricating prepare combines conventional metallurgical ability with present day exactness hardware. We utilize both open kick the bucket and closed pass on producing strategies depending on your component complexity and amount necessities. The closed kick the bucket strategy conveys more tightly resiliences for complex geometries, whereas open pass on manufacturing suits bigger, less complex shapes with most extreme basic integrity.

Heat treatment is vital for accomplishing ideal properties. We apply arrangement toughening taken after by precipitation solidifying to create the alloy's characteristic quality. This controlled warm handling makes fine accelerates all through the fabric lattice, essentially upgrading mechanical performance.

What is the Production Process of Inconel X-750 Forgings?

Step 1: Fabric Determination – We source high-purity Inconel X-750 crude materials solely from qualified providers, guaranteeing reliable chemistry and performance.

Step 2: Warming – Billets are warmed to fashioning temperature (regularly 1040-1150°C) in controlled climate heaters to anticipate oxidation.

Step 3: Producing – Utilizing our 100+ exactness machines over 8 generation lines, we shape the warmed fabric through water powered presses or hammers, refining the grain structure.

Step 4: Warm Treatment – Components experience arrangement strengthening at around 1095°C, taken after by controlled cooling and age solidifying at 704-760°C.

Step 5: Machining – Accuracy machining accomplishes your indicated measurements and surface wraps up with tight tolerances.

Step 6: Quality Review – Each piece experiences comprehensive testing some time recently approval.

Quality Inspection

Quality isn't fair a guarantee at TSM Technology—it's our establishment. Each manufacturing passes through our thorough review protocols:

- Dimensional Review: Exact estimation confirmation against your specifications

- Ultrasonic Testing (UT): Identifies inner discontinuities and guarantees auxiliary soundness

- Radiographic Testing (RT): Recognizes inside surrenders undetectable to other methods

- Eddy Current Testing: Confirms surface and near-surface integrity

- Chemical Investigation: Affirms fabric composition meets detail requirements

- Mechanical Testing: Approves pliable quality, surrender quality, and stretching properties

- Hardness Testing: Guarantees legitimate warm treatment effectiveness

Our certifications incorporate ISO 9001, AS9100D, and AS9120, illustrating our commitment to aerospace-grade quality standards.

Why Choose TSM Technology?

Extensive Involvement

With over 14 a long time serving 70+ nations, we get it your worldwide prerequisites and conveyance expectations.

Technical Skill

Our building group gives comprehensive discussion, making a difference you select the right determinations for your application.

Flexible Customization

From model to generation volumes, we suit your one of a kind shape, estimate, and handling requirements.

Advanced Fabricating

Our 50,000㎡ cutting edge office houses total generation capabilities from dissolving to last assessment, guaranteeing quality control at each stage.

Proven Execution

AS9100D certification affirms our capability to meet aviation industry's rigid requirements—the most elevated benchmark for accuracy and reliability.

Supply Steadiness

With 1000 tons yearly capacity and coordinates supply chain, we guarantee reliable conveyance schedules.

Package and Shipping

We secure your speculation through each mile of travel. Each manufacturing gets person wrapping in anti-corrosion paper or plastic film. Components are at that point secured in durable wooden cases or steel cartons with padding materials anticipating development amid transport. For sending out shipments, we apply fumigation treatment to wooden bundling materials assembly worldwide phytosanitary measures. Clear labeling incorporates your arrange points of interest, taking care of informational and goal information. Standard conveyance time runs 10-25 days depending on the arrangement complexity and amount. Our Hong Kong coordination center encourages effective shipping around the world with solid following all through transit.

FAQ

Q1: What is the greatest temperature resistance of Inconel X-750?

A: This combination keeps up fabulous mechanical properties at persistent working temperatures up to 2,000°F (1,093°C), making it perfect for your high-temperature applications.

Q2: Can these forgings be utilized in fly engines?

A: Completely. The combination of high-temperature quality, oxidation resistance, and creep-rupture properties makes these components idealize for fly motor turbine areas and deplete systems.

Q3: What's the contrast between open pass on and closed pass on forging?

A: Open kick the bucket fashioning suits with bigger, less difficult shapes and offers more prominent adaptability for custom sizes. Closed kick the bucket producing produces complex geometries with more tightly resiliencies and superior surface finish—we'll suggest the best strategy for your application.

Q4: Do you give fabric certificates?

A: Yes, each arrange incorporates Fabric Test Certificates (MTC) recording chemical composition and mechanical properties. SGS third-party testing reports are moreover accessible upon request.

Q5: Can you create custom shapes past standard rounds and blocks?

A: Certainly. Our experienced building group works with your drawings to create custom forgings coordinating your correct details, counting complex geometries requiring specialized tooling.

Q6: What is the least arrange quantity?

A: We suit both model amounts and generation volumes. Contact us to talk about your particular requirements—we're adaptable in supporting your extend needs.

Q7: How do you guarantee steady quality over huge orders?

A: Our ISO 9001 and AS9100D quality administration frameworks guarantee that control all through generation. Each piece experiences the same thorough assessment convention, with factual handle control observing basic parameters.

Contact Us

Ready to discuss your Inconel X-750 Forgings requirements? Our technical team is here to help you select the right specifications and answer your application questions. We typically respond within 24 hours with technical guidance and quotations. Free samples are available for qualified applications, allowing you to verify material performance before committing to production quantities.

Email: info@tsmnialloy.com

Learn about our latest products and discounts through SMS or email

Learn about our latest products and discounts through SMS or email