- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

Are Nickel Screws Resistant to Acids and Alkalis?

Nickel screws are very resistant to both acids and bases, which makes them an essential fastening option for harsh industrial settings. Nickel can create a solid oxide layer that protects the metal below from corrosive attack. This is why they are so resistant to chemicals. Nickel screws keep their structural integrity and mechanical properties much better than steel or zinc-plated alternatives when they are exposed to acidic or alkaline circumstances. Nickel-based fasteners are the best choice for chemical processing plants, marine uses, and aerospace systems that will be exposed to corrosive substances because they work so well.

Understanding the Corrosion Resistance of Nickel Screws

The amazing corrosion resistance of nickel-based fasteners comes from basic metallurgical principles that set these metals apart from other materials. Nickel naturally forms a thin, stick-together oxide film when it comes into contact with oxidizing surroundings. This film protects nickel from further chemical attack.

The Science Behind Nickel's Protective Properties

Nickel's corrosion resistance is based on the formation of an inactive layer mostly made up of nickel oxide and hydroxide compounds. This protective film doesn't change when the pH level changes, so it works well in both acidic and basic settings. Iron-based alloys make porous, non-protective rust layers. Nickel's oxide film, on the other hand, keeps its good adhesion and can fix itself when it gets small scratches.

Based on ASTM G28 standards, research shows that pure nickel corrodes at a rate of less than 0.1 mm per year in concentrated sulfuric acid at room temperature. Better performance is seen in more advanced nickel alloys like Hastelloy and Inconel. Some types can keep their shape in boiling hydrochloric acid solutions.

Enhanced Performance Through Alloying

Today's nickel screws have extra elements added to them that make them even more resistant to chemicals. Adding chromium makes it more resistant to oxidation and increases the inactive range in acidic solutions. The amount of molybdenum in something makes it much more resistant to pitting and crevice rust in places where chloride is present. Adding tungsten makes the material very stable in reducing acids and high-temperature alkaline liquids.

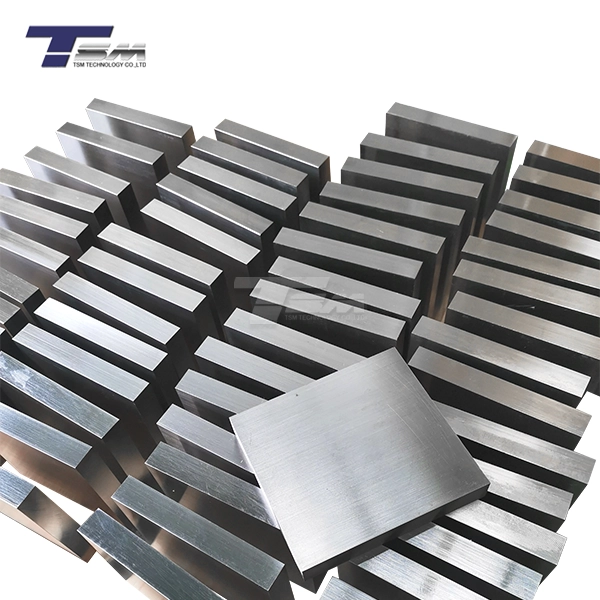

Nickel screws made by TSM Technology are made from alloys that have been carefully tuned to meet ASTM, DIN, and JIS standards. The company's advanced manufacturing methods make sure that the microstructures are all the same. This makes the materials more resistant to corrosion while keeping the mechanical properties that are needed for important fastening uses.

Comparative Analysis: Nickel Screws vs Other Screw Materials in Acidic and Alkaline Environments

When choosing materials for corrosive settings, it's important to look at how they work in a wide range of chemical conditions. Nickel-based screws always work better than other materials in both acidic and alkaline environments. However, different methods may be better for some uses because of cost-benefit concerns.

Performance Against Common Acids

Grades 304 and 316 stainless steel work well in mildly acidic environments, but they break down a lot in reducing acids like sulfuric or hydrochloric acid. Nickel alloys are very good at resisting corrosion in almost all acidic situations. Some grades, like Hastelloy C-276, work especially well in mixed acid solutions that contain chlorides and fluorides.

Titanium fasteners work better in oxidizing acids but can break down in reducing conditions where hydrogen can dissolve in the air. Materials made of brass and bronze don't hold up well against acids and shouldn't be used for most chemical processing tasks. Coatings on carbon steel offer short-term protection, but they don't offer the long-term dependability needed for important works.

Alkaline Environment Performance

Because of the unique problems that come up in alkaline environments, nickel-based products are better than most other options. Aluminum alloys rust quickly in acidic solutions because amphoteric behavior breaks down protective oxide films. Copper-based alloys have a modest level of resistance, but they may crack from stress corrosion in solutions that contain ammonia.

Nickel screws work great in alkaline settings and can keep their shape in high-temperature, concentrated sodium hydroxide solutions. Because the material is stable across a wide pH range, it is very useful for cleaning with alkaline cleansers or in situations where the chemicals are changing.

Applications and Benefits of Nickel Screws in Acidic and Alkaline Environments

Nickel fasteners are used a lot in the chemical processing industries on equipment that works with corrosive materials during production processes. These special fasteners are used in reactor tanks, distillation columns, and purification systems in pharmaceutical factories. Corroded hardware could contaminate the product, which would be against regulations and quality standards.

Critical Applications in Chemical Manufacturing

Nickel-based fasteners are used a lot in heat exchangers, pressure tanks, and piping systems that are exposed to acidic crude oil fractions and alkaline treating solutions in petrochemical refineries. The better resistance to corrosion keeps it from failing too soon, which could cause expensive unplanned shutdowns or safety issues. When compared to regular fasteners, maintenance intervals can be greatly increased, which lowers running costs and raises facility availability.

When seawater and chemicals used to process hydrocarbons come together on offshore oil platforms, they create very harsh conditions that are very likely to corrode things. Nickel screws work reliably in these situations and keep their structure even when they are constantly exposed to chloride-containing liquids and changes in temperature.

Marine and Aerospace Applications

Nickel-based fasteners are used in shipbuilding for important structural links that are exposed to seawater and marine atmospheres. The material doesn't crack when exposed to chloride, which makes it reliable over time, which is important for keeping the vessel safe and running smoothly. Some nickel alloys are nonmagnetic, which keeps them from interfering with sensitive navigation equipment and is especially useful in naval uses.

Nickel fasteners are used by aerospace companies in engine parts and aircraft structures that are exposed to fuel additives, hydraulic fluids, and the environment. These parts need to be very resistant to chemicals. Nickel alloys have a high strength-to-weight ratio, which helps with efforts to reduce weight while keeping the structure strong in tough service circumstances.

Because TSM Technology can make custom solutions from M2.5 to M32 sizes and up to 1990mm in length to meet specific needs, their manufacturing skills support a wide range of applications. The company has more than 100 precision machines that can make complicated shapes while keeping the tight tolerances needed for important uses.

How to Choose the Right Nickel Screws for Acid and Alkali Resistance?

To choose the right nickel fasteners, you need to carefully consider the environment, the mechanical needs, and the compatibility factors that affect how well they work in the long run. Specifications for materials must match the chemicals they will be exposed to, taking into account temperature ranges, stress levels, and how well they work with other parts galvanically.

Alloy Selection Criteria

There are different levels of chemical resistance in nickel alloys that are best for different settings. Monel alloys work great in seawater and mildly acidic environments and have great mechanical qualities as well. Higher types of Inconel work better at high temperatures and are less likely to rust. When it comes to chemical conditions that are very harsh, like mixed acid systems and high-temperature alkaline solutions, hastelloy alloys work very well.

Temperature plays a big role in choosing materials because high temperatures can speed up the rusting process and change how stable protective oxide films are. Nickel alloys have great properties at a lot of different temperatures, but some grades may be better for really harsh circumstances.

Procurement Strategy and Quality Assurance

To successfully buy nickel fasteners, you need to work with suppliers who can give you certified materials with full paperwork that shows where they came from. Certification to EN10204 3.1/3.2 makes sure that the material composition is correct, and inspection records from a third party confirm that the mechanical properties and dimensions are correct.

TSM Technology's complete quality control system meets these needs with strict testing methods and detailed record-keeping steps. Because the company has been making nickel alloys for 14 years, they know how to suggest the best solutions for each purpose while also making sure they meet international standards like ASTM, DIN, JIS, BS, and GB/T.

Maintenance and Longevity of Nickel Screws in Chemical Environments

When nickel screws are maintained properly, they last a lot longer and keep their corrosion resistance, which makes them useful for chemical uses. Regular checking protocols help find problems before they damage the system, and the right cleaning protocols keep the protective films on the surface.

Inspection and Monitoring Procedures

Visual inspection is still the best way to check the state of a fastener that is already in use. Look for surface discoloration, pitting, or mechanical damage that could affect how well it works. Ultrasonic testing and other advanced methods may be needed for important tasks where problems inside the object could happen over time.

When nickel screws touch metals that are not galvanically compatible, extra care needs to be taken. Using the right isolation methods and cathodic protection systems can help slow down rust that could damage the fastener and other parts nearby.

Preventive Maintenance Best Practices

When cleaning, you should use solvents that are compatible and stay away from rough methods that could damage protective oxide films. Most of the time, alkaline cleaners work well and don't weaken nickel's rust resistance. On the other hand, acidic cleaners need to be carefully chosen to avoid unwanted interactions.

When specifying torque, it's important to take into account the unique qualities of nickel alloys, which may not behave the same way as steel fasteners. Using the right compounds to lubricate helps keep clamping forces constant and stops galling.

TSM Technology: Your Trusted Partner for Superior Nickel Fasteners

TSM Technology is the world leader in making high-quality nickel screws that are designed to work in harsh chemical and industrial environments. Our 3,200㎡ state-of-the-art facility has more than 70 precision machines, such as 5-axis machining centers, CNC lathes, and thread rolling equipment, that allow us to make fasteners from M2.5 to M32 with great accuracy and consistency. We have been making these kinds of fasteners for over 14 years.

We have a wide range of products, including nickel alloys like Monel, Inconel, Incoloy, and Hastelloy. We carefully choose and process each one to meet the strict needs of the aerospace, marine, offshore, pharmaceutical, and petroleum industries. We can reliably meet both standard and unique needs with supply capacities ranging from 100,000 to 300,000 pieces and shipping times usually between 10 and 25 days.

We still put a lot of emphasis on quality control, and all of our products meet foreign standards like ASTM, DIN, JIS, BS, and GB/T. The EN10204 3.1/3.2 certification and third-party inspection reports give you the proof you need for important uses, and our low minimum order number of 100 pieces and free samples help you meet the needs of testing and evaluation.

Conclusion

Nickel screws are very resistant to both acids and alkalis because they make stable protective oxide layers that stay in place in a wide range of temperatures and pH levels. These materials work better than regular ones, which is why they are needed in chemical processing, marine, aircraft, and other demanding situations where corrosion resistance affects safety and dependability. The best service life and efficiency are achieved by making the right choice based on the environment and then maintaining it in the right way. TSM Technology has a wide range of production skills and quality control systems that can meet the needs of a wide range of industries. They can create custom solutions based on their deep knowledge of nickel alloy technology.

FAQ

1.What specific acids and alkalis can nickel screws resist?

Nickel screws demonstrate excellent resistance to the most common acids including sulfuric, hydrochloric, and nitric acids at moderate concentrations and temperatures. They also perform well in alkaline solutions such as sodium hydroxide and ammonia-based compounds. Advanced nickel alloys like Hastelloy grades provide exceptional performance in mixed acid systems and high-temperature caustic environments.

2.How do I determine the right nickel alloy for my specific application?

Alloy selection depends on the specific chemicals involved, operating temperature, mechanical stress requirements, and galvanic compatibility factors. Monel alloys suit general marine and mild chemical environments, while Inconel grades excel in high-temperature oxidizing conditions. Hastelloy alloys provide maximum chemical resistance for the most aggressive environments. Consulting with experienced suppliers helps ensure optimal material selection.

3.What maintenance is required for nickel screws in chemical environments?

Regular visual inspection for surface changes, proper cleaning with compatible solvents, and monitoring for galvanic corrosion when contacting dissimilar metals comprise essential maintenance activities. Avoiding abrasive cleaning methods preserves protective oxide films, while appropriate torque specifications prevent mechanical damage during installation and service.

Partner with TSM Technology for Premium Nickel Screws

TSM Technology delivers industry-leading nickel screws manufacturer solutions with proven acid and alkali resistance for your most challenging applications. Our advanced manufacturing capabilities, comprehensive alloy selection, and rigorous quality control ensure reliable performance in demanding chemical environments. With over 14 years of expertise and certifications meeting international standards, we provide customized fastening solutions backed by technical support and competitive delivery schedules. Contact our team at info@tsmnialloy.com to discuss your specific requirements, request samples, or explore bulk purchasing options that optimize your procurement efficiency and operational reliability.

References

Davis, J.R. (2000). Nickel, Cobalt, and Their Alloys. ASM International Materials Park.

Ahmad, Z. (2006). Principles of Corrosion Engineering and Corrosion Control. Butterworth-Heinemann.

Cramer, S.D. and Covino, B.S. (2003). ASM Handbook Volume 13A: Corrosion Fundamentals, Testing, and Protection. ASM International.

Rebak, R.B. (2005). Nickel Alloys for Corrosive Environments. Advanced Materials and Processes, 163(2), 19-23.

Fontana, M.G. and Greene, N.D. (1987). Corrosion Engineering. McGraw-Hill Chemical Engineering Series.

Special Metals Corporation (2004). High-Performance Alloys for Resistance to Aqueous Corrosion. Publication SMC-026.

Learn about our latest products and discounts through SMS or email