Understanding Inconel 625 and Its Properties

Composition and Characteristics of Inconel 625

Inconel 625 is a remarkable nickel-based superalloy known for its exceptional combination of strength and corrosion resistance. Its composition typically includes about 58% nickel, 20-23% chromium, 8-10% molybdenum, and smaller amounts of niobium, iron, and other elements. This unique blend imparts Inconel 625 with outstanding resistance to oxidation, carburization, and other forms of high-temperature degradation.

The alloy's high nickel content provides excellent resistance to chloride stress corrosion cracking, while the chromium offers protection against oxidizing environments. Molybdenum and niobium contribute to its impressive strength and stability at elevated temperatures. These properties make Inconel 625 an ideal choice for fasteners in extreme environments.

Advantages of Inconel 625 in Fastener Applications

Inconel 625 fasteners offer numerous advantages in demanding applications. Their exceptional corrosion resistance makes them suitable for use in marine environments, chemical processing plants, and offshore oil and gas installations. The alloy's high strength-to-weight ratio is beneficial in aerospace applications where weight reduction is crucial.

Moreover, Inconel 625 bolts maintain their mechanical properties at temperatures ranging from cryogenic to over 1000°C, making them ideal for high-temperature fastening solutions. Their resistance to fatigue and thermal cycling further enhances their reliability in dynamic and thermally stressed environments.

Challenges in Machining and Forming Inconel 625

Despite its advantageous properties, working with Inconel 625 presents certain challenges. The alloy's high strength and work-hardening characteristics can make traditional machining processes difficult and time-consuming. Cutting tools wear quickly when machining Inconel 625, necessitating frequent replacements and increasing production costs.

Forming Inconel 625 can also be challenging due to its high yield strength and tendency to work harden rapidly. These properties make cold forming processes, including cold heading, more demanding compared to working with standard steels. However, with proper techniques and tooling, these challenges can be overcome, allowing for the efficient production of high-quality Inconel 625 fasteners.

Cold Heading Process for Inconel 625 Fasteners

Principles of Cold Heading

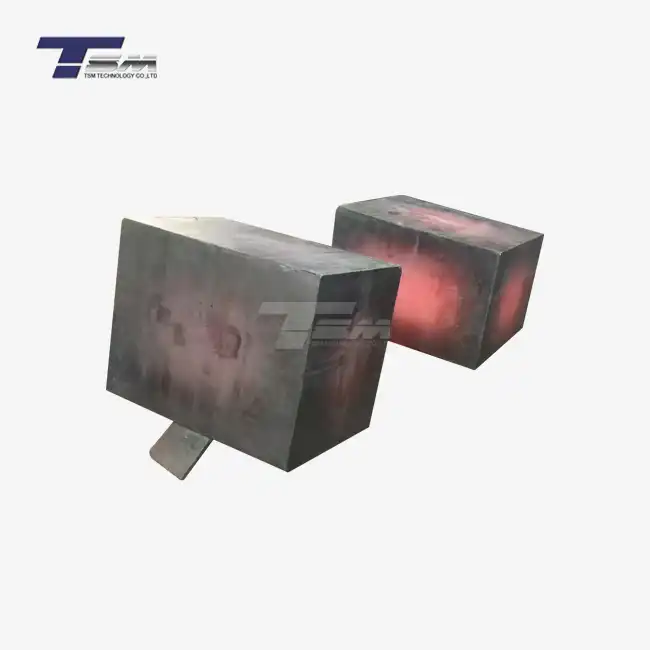

Cold heading is a metal forming process that shapes metal at room temperature through a series of dies using high pressure. This technique is particularly effective for producing fasteners, including those made from Inconel 625. The process begins with a wire or rod of the alloy, which is then subjected to a sequence of forming operations.

The fundamental principle behind cold heading is the plastic deformation of metal. When subjected to stresses beyond its yield strength, the metal flows plastically, allowing it to be shaped without fracturing. For Inconel 625, this process requires significant force due to the alloy's high strength and work-hardening properties.

Stages in Cold Heading Inconel 625 Fasteners

The cold heading process for Inconel 625 fasteners typically involves several stages:

- Cut-off: The wire or rod is cut to the required length for the fastener.

- Upsetting: The cut piece is compressed axially, causing it to expand radially and form the fastener head.

- Extrusion: The material is forced through a die to form the shank of the fastener.

- Trimming: Excess material is removed to achieve the final shape.

- Threading: For bolts and screws, threads are either rolled or cut into the shank.

Each stage requires precise control of pressure, speed, and die design to ensure the Inconel 625 flows correctly without developing defects or excessive work hardening.

Tooling and Equipment for Cold Heading Inconel 625

Cold heading Inconel 625 requires specialized tooling and equipment due to the alloy's high strength and work-hardening characteristics. The dies and punches used in the process must be made from materials with exceptional hardness and wear resistance, such as tungsten carbide or special tool steels.

The heading machines used for Inconel 625 fasteners are typically high-tonnage presses capable of exerting the substantial forces needed to form this robust alloy. These machines often feature multiple stations, allowing for a series of forming operations to be performed in sequence.

Advanced process control systems are essential for maintaining tight tolerances and ensuring consistent quality in Inconel 625 fastener production. These systems monitor and adjust parameters such as force, speed, and material flow in real-time, compensating for variations in the alloy's properties and environmental conditions.

Optimizing Cold Heading for Inconel 625 Fasteners

Material Preparation and Conditioning

Proper material preparation is crucial for the successful cold heading of Inconel 625 fasteners. The starting wire or rod must be of high quality, with consistent composition and properties. Annealing the material before cold heading can improve its formability by reducing internal stresses and optimizing grain structure.

Surface conditioning is also important. The wire or rod should be free from surface defects, oxides, or contaminants that could affect the forming process or the final product's quality. Cleaning and, in some cases, applying suitable lubricants can enhance the material's flow characteristics during cold heading.

Process Parameters and Controls

Optimizing process parameters is key to achieving high-quality Inconel 625 fasteners through cold heading. Critical factors include:

- Forming speed: Controlling the rate of deformation is crucial to prevent excessive work hardening or material failure.

- Die design: Optimized die geometries can improve material flow and reduce the risk of defects.

- Temperature control: While cold heading occurs at room temperature, managing heat generation during the process is important to maintain consistent material properties.

- Lubrication: Proper lubrication reduces friction, improves material flow, and extends die life.

Advanced process monitoring and control systems play a vital role in maintaining these parameters within optimal ranges throughout the production run.

Quality Control and Testing for Cold Headed Inconel 625 Fasteners

Rigorous quality control is essential for ensuring the reliability and performance of cold headed Inconel 625 fasteners. Key aspects of quality control include:

- Dimensional inspection: Precise measurements to verify conformance to specifications.

- Material testing: Evaluating mechanical properties such as tensile strength, yield strength, and elongation.

- Microstructure analysis: Examining grain structure and potential defects through metallographic techniques.

- Corrosion resistance testing: Verifying the fastener's ability to withstand harsh environments.

- Non-destructive testing: Using methods like ultrasonic or magnetic particle inspection to detect internal defects.

Implementing statistical process control (SPC) techniques helps monitor production trends and identify opportunities for continuous improvement in the cold heading process for Inconel 625 fasteners.

Conclusion

Cold heading techniques for Inconel 625 fasteners represent a sophisticated manufacturing approach that leverages the alloy's exceptional properties while overcoming its formidability challenges. By carefully controlling material preparation, process parameters, and quality assurance measures, manufacturers can produce high-performance Inconel 625 bolts and other fasteners that meet the demanding requirements of aerospace, marine, and chemical processing industries. As technology advances, further refinements in cold heading processes for superalloys like Inconel 625 will continue to expand the possibilities for creating robust, reliable fastening solutions for the most extreme applications.

Contact Us

For more information about our superior Inconel 625 fasteners and other high-performance alloy products, please don't hesitate to contact TSM TECHNOLOGY at info@tsmnialloy.com. Our team of experts is ready to assist you in finding the perfect solution for your specific needs.