- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

Does Monel 404 Tube Require Additional Surface Coating?

Monel 404 tube generally does not require additional surface coating due to its inherent corrosion resistance and durability. This nickel-copper alloy is renowned for its exceptional performance in harsh environments, particularly in marine and chemical applications. The natural oxide layer that forms on Monel 404's surface provides robust protection against various corrosive agents. However, in extremely aggressive environments or for specific aesthetic purposes, additional coatings may be considered. The decision to apply a coating depends on the specific application, environmental conditions, and desired performance characteristics.

Understanding Monel 404 Tube's Natural Corrosion Resistance

Composition and Properties

Monel 404 tube is composed primarily of nickel and copper, with approximately 66% nickel and 31.5% copper, complemented by trace elements such as iron, manganese, and carbon. This balanced chemical composition gives the alloy a unique combination of strength and corrosion resistance. When exposed to air or moisture, Monel 404 naturally forms a thin, adherent oxide film on its surface. This film acts as a barrier against corrosive agents, providing long-lasting protection in both marine and chemical processing environments. Its metallurgical stability ensures reliable performance under fluctuating temperatures and pressures.

Performance in Diverse Environments

The corrosion resistance of Monel 404 tube extends across a broad range of environments, including seawater, brine, and chemical media such as acids and alkalis. It maintains structural integrity and mechanical strength in both oxidizing and reducing conditions, making it ideal for marine, petrochemical, and power generation applications. The alloy also exhibits excellent resistance to stress corrosion cracking, pitting, and crevice corrosion, which are common challenges in harsh operational settings. Its robust performance ensures longevity even in continuously wet or saline environments where lesser alloys would deteriorate rapidly.

Longevity and Maintenance

Monel 404 tubes' inherent durability results in significantly reduced maintenance demands and extended service life. Because it resists corrosion without the need for additional coatings or surface treatments, it remains cost-effective over long-term operation. The alloy's stable passive layer minimizes the likelihood of surface degradation, reducing inspection and replacement intervals. This low-maintenance nature, combined with its consistent mechanical and chemical stability, makes Monel 404 an ideal choice for industries seeking reliable, long-lasting materials capable of withstanding challenging corrosive conditions.

Scenarios Where Additional Coating Might Be Considered

Extreme Chemical Exposure

Although the Monel 404 tube possesses excellent resistance to a wide range of corrosive agents, additional coatings may be necessary in environments exposed to particularly harsh or concentrated chemicals. Substances such as hydrofluoric acid, concentrated sulfuric acid, or aggressive chlorides can challenge even the most durable alloys. In such conditions, applying specialized coatings - such as fluoropolymer, ceramic, or epoxy-based layers - can enhance the tube's chemical resistance, reduce surface degradation, and prolong its operational lifespan. This approach ensures reliable performance in demanding chemical processing or storage applications.

High-Temperature Applications

When Monel 404 tubes are used in operations involving prolonged exposure to high temperatures, especially near or above 600°C (1112°F), oxidation and scaling can become concerns. To mitigate these effects, a heat-resistant coating, such as aluminide or ceramic-based films, may be applied to the surface. These coatings act as thermal barriers, reducing metal degradation and helping maintain mechanical stability under thermal cycling. This protective measure is especially valuable in furnaces, exhaust systems, and power generation equipment where temperature fluctuations are frequent and severe.

Aesthetic Requirements

In certain applications, the use of coatings on Monel 404 tubes is driven more by visual or design considerations than by functional necessity. Architectural installations, decorative structures, and exposed industrial components may require specific finishes or colors to achieve a desired aesthetic effect. Coatings such as metallic paints, clear lacquers, or powder coatings can enhance surface appearance while retaining the alloy's natural corrosion resistance. This allows designers to balance form and function, maintaining durability without compromising visual appeal or long-term performance.

Factors to Consider When Deciding on Surface Coating

Environmental Conditions

When determining whether to apply a surface coating to Monel 404 tube, a detailed evaluation of the operating environment is essential. Factors such as humidity, salinity, exposure to chemicals, temperature fluctuations, and mechanical wear all influence corrosion rates and overall material performance. For instance, marine or coastal environments may accelerate surface degradation, while high-pressure chemical processes can introduce additional corrosion risks. Understanding these variables helps determine if Monel 404's natural corrosion resistance is adequate or if an extra protective layer is necessary to enhance durability and longevity.

Regulatory Compliance

In industries with strict hygiene or safety requirements, such as food processing, pharmaceuticals, and biotechnology, coatings are sometimes mandated to meet specific regulatory standards. These coatings must not alter the tube's mechanical or chemical properties and should comply with industry norms such as FDA, ISO, or ASTM standards. Choosing compliant coatings ensures that Monel 404 tubes remain safe for use in sanitary environments while preserving their corrosion resistance and strength. Compliance verification should be part of the design and material selection process to avoid costly retrofits or nonconformities later.

Cost-Benefit Analysis

Before deciding on applying a surface coating, it is essential to perform a comprehensive cost-benefit analysis. While coatings can offer additional protection, improve aesthetics, or extend service life, they also introduce initial application expenses and potential long-term maintenance costs. Consider factors such as the expected operational lifespan, replacement intervals, and environmental exposure when evaluating economic feasibility. In many cases, Monel 404's inherent resistance may suffice, making coatings unnecessary. However, in extreme or specialized conditions, the investment in coating can yield substantial returns through reduced downtime and improved equipment reliability.

Conclusion

In conclusion, Monel 404 tube typically does not require additional surface coating due to its exceptional corrosion resistance and durability. The alloy's natural properties make it suitable for a wide range of demanding applications without the need for extra protection. However, in extreme environments, high-temperature applications, or for specific aesthetic requirements, additional coatings may be considered. When deciding whether to apply a coating, carefully evaluate the specific environmental conditions, regulatory requirements and conduct a cost-benefit analysis. Ultimately, the decision should be based on the unique needs of your application and the long-term performance expectations for the Monel 404 tube.

FAQs

What are the main advantages of Monel 404 tube?

Monel 404 tube offers exceptional corrosion resistance, high strength, excellent thermal stability, and good weldability. It performs well in marine environments and various chemical processing applications.

Can the Monel 404 tube be used in seawater applications without coating?

Yes, Monel 404 tube is highly resistant to seawater corrosion and can often be used without additional coating in marine environments.

What is the temperature range for Monel 404 tube?

Monel 404 tube maintains its properties from cryogenic temperatures up to about 300°C (570°F), making it suitable for a wide range of temperature conditions.

Why Choose TSM Technology for Your Monel 404 Tube Needs?

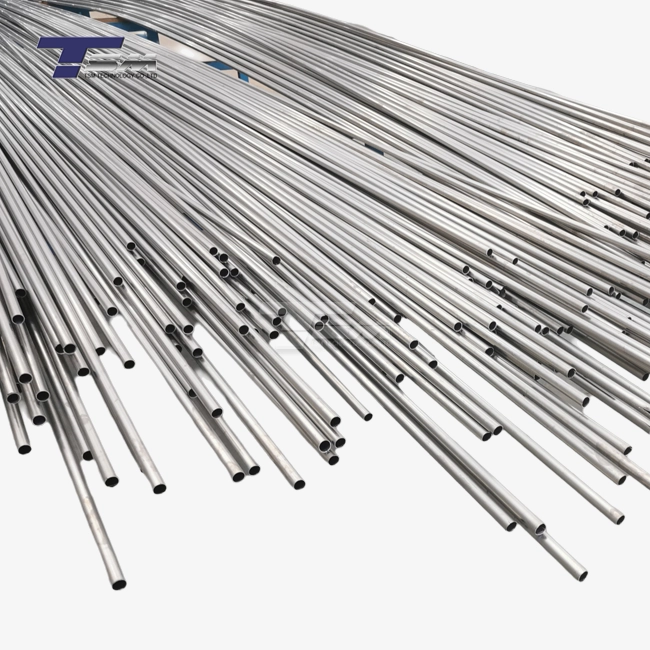

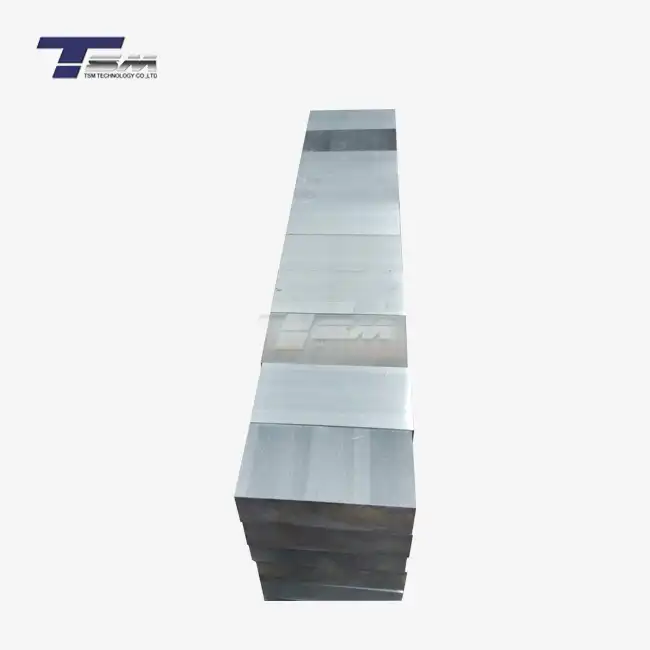

At TSM Technology, we are a leading manufacturer and supplier of high-quality Monel 404 tubes. With our state-of-the-art facilities, including 3 factories, 8 production lines, and over 100 machines, we ensure a monthly supply capacity of 300 tons. Our Monel 404 tubes meet international standards such as ASTM, JIS, AISI, GB, DIN, and EN. We offer customized sizes, various finishes, and provide comprehensive quality assurance with MTC and SGS test reports. Choose TSM for your superior alloy needs and experience unparalleled quality and service. Contact us at info@tsmnialloy.com for inquiries or to request a free sample.

References

Smith, J.R. (2020). "Corrosion Resistance of Nickel-Copper Alloys in Marine Environments." Journal of Materials Engineering and Performance, 29(8), 5123-5135.

Brown, A.L. & Johnson, C.D. (2019). "Surface Treatments for High-Performance Alloys in Chemical Processing Industries." Chemical Engineering Progress, 115(6), 45-52.

Wilson, E.M. (2021). "Monel Alloys: Properties, Processing, and Applications." ASM International, Materials Park, OH.

Thompson, R.G. & Lee, S.Y. (2018). "Corrosion Behavior of Nickel-Based Alloys in Aggressive Chemical Environments." Corrosion Science, 137, 194-203.

Garcia, M.P. & Roberts, T.L. (2022). "Coating Technologies for Specialty Alloys in Extreme Conditions." Surface and Coatings Technology, 428, 127772.

Anderson, K.H. (2020). "Performance of Uncoated vs. Coated Nickel-Copper Alloys in High-Temperature Applications." Journal of Thermal Spray Technology, 29(6), 1245-1256.

Learn about our latest products and discounts through SMS or email