- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

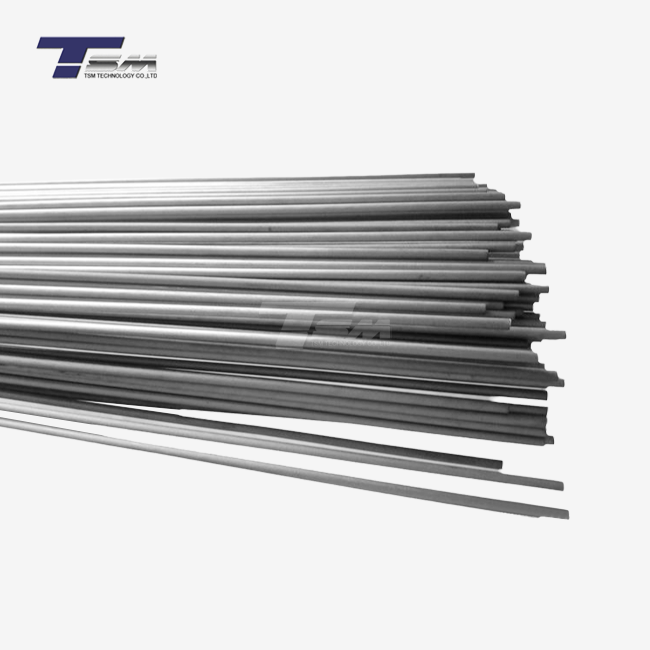

How Pure Nickel 200 Tube Enhances Heat Exchange Efficiency?

Pure Nickel 200 tube significantly enhances heat exchange efficiency due to its exceptional thermal conductivity, corrosion resistance, and durability. These properties allow for superior heat transfer in various industrial applications, including chemical processing, power generation, and aerospace. The high purity of Nickel 200 ensures consistent performance across a wide temperature range, minimizing downtime and maintenance costs. Additionally, its ability to withstand harsh environments makes it an ideal choice for heat exchangers in demanding conditions, ultimately leading to improved overall system efficiency and longevity.

Properties and Characteristics of Nickel 200 Tube

Chemical Composition and Purity

Nickel 200 tube is renowned for its high purity, typically containing at least 99.0% nickel. This exceptional purity level contributes to its superior performance in heat exchange applications. The remaining composition may include trace amounts of carbon, manganese, iron, sulfur, and copper, which are carefully controlled to maintain the alloy's desired properties. The high nickel content ensures excellent resistance to corrosion and oxidation, making it suitable for use in various aggressive environments.

Physical Properties

The physical properties of Nickel 200 pipe play a crucial role in its heat exchange efficiency. It boasts a density of approximately 8.89 g/cm³, providing a good balance between strength and weight. The melting point of Nickel 200 is around 1435°C (2647°F), allowing it to maintain its structural integrity at high temperatures. Its thermal conductivity, which is approximately 91 W/(m·K) at room temperature, enables efficient heat transfer in exchanger applications.

Mechanical Strength and Ductility

Nickel 200 tube exhibits impressive mechanical properties that contribute to its durability and longevity in heat exchange systems. It has a tensile strength ranging from 490 to 550 MPa and a yield strength of 180 to 220 MPa, depending on the material's condition. The elongation of Nickel 200 can reach up to 50%, indicating excellent ductility. These mechanical characteristics allow the material to withstand thermal cycling and pressure fluctuations commonly encountered in heat exchanger operations.

Heat Exchange Efficiency Improvements with Nickel 200 Tube

Thermal Conductivity Advantages

One of the primary reasons the Nickel 200 tube enhances heat exchange efficiency is its superior thermal conductivity. With a thermal conductivity value of approximately 91 W/(m·K), it outperforms many other materials used in heat exchangers. This high conductivity allows for rapid heat transfer between fluids, resulting in more efficient energy exchange and improved overall system performance. The consistent thermal properties of Nickel 200 across a wide temperature range further contribute to its effectiveness in various heat exchange applications.

Corrosion Resistance and Longevity

The exceptional corrosion resistance of Nickel 200 pipe plays a crucial role in maintaining heat exchange efficiency over time. Its ability to withstand corrosive environments, including exposure to various acids, alkalis, and salt solutions, prevents degradation of the heat transfer surfaces. This corrosion resistance ensures that the thermal conductivity and surface characteristics of the Nickel 200 tube remain consistent throughout its operational life, minimizing efficiency losses and reducing the need for frequent maintenance or replacement.

Surface Characteristics and Fouling Resistance

The surface characteristics of Nickel 200 tube contribute significantly to its heat exchange efficiency. The material's smooth surface finish reduces friction and turbulence in fluid flow, promoting better heat transfer. Additionally, Nickel 200 demonstrates excellent resistance to fouling, which is the accumulation of unwanted deposits on heat transfer surfaces. This fouling resistance helps maintain optimal heat exchange performance over extended periods, reducing the frequency of cleaning and maintenance operations in industrial settings.

Applications and Case Studies of Nickel 200 Tube in Heat Exchangers

Chemical Processing Industry

In the chemical processing industry, Nickel 200 tube has proven invaluable for heat exchangers handling corrosive substances. Its resistance to a wide range of chemicals, combined with excellent heat transfer properties, makes it ideal for applications such as acid production and petrochemical processing. For instance, in sulfuric acid plants, Nickel 200 heat exchangers have demonstrated superior performance and longevity compared to traditional materials, resulting in increased production efficiency and reduced maintenance costs.

Power Generation Sector

The power generation sector benefits greatly from the use of Nickel 200 pipe in heat exchange systems. In nuclear power plants, where reliability and safety are paramount, Nickel 200 tube heat exchangers play a crucial role in steam generation and condensation processes. The material's ability to withstand high temperatures and pressures, coupled with its excellent heat transfer characteristics, contributes to improved energy efficiency and plant reliability. Additionally, in geothermal power plants, Nickel 200 tube heat exchangers have demonstrated exceptional resistance to the corrosive geothermal fluids, resulting in extended equipment life and reduced operational costs.

Aerospace and Defense Applications

In the aerospace and defense industries, where weight, performance, and reliability are critical factors, Nickel 200 tube heat exchangers have found numerous applications. Aircraft environmental control systems utilize Nickel 200 heat exchangers to manage cabin temperature and humidity efficiently. The material's high strength-to-weight ratio and excellent thermal properties contribute to fuel efficiency and overall aircraft performance. In defense applications, such as shipboard desalination plants, Nickel 200 tube heat exchangers demonstrate superior corrosion resistance in seawater environments, ensuring consistent fresh water production for extended missions.

Conclusion

Pure Nickel 200 tube significantly enhances heat exchange efficiency through its exceptional thermal conductivity, corrosion resistance, and durability. Its high purity and consistent performance across various temperatures make it an ideal choice for demanding industrial applications. The material's ability to maintain its properties in harsh environments, coupled with its resistance to fouling, ensures long-term efficiency and reduced maintenance requirements. As industries continue to seek improved energy efficiency and reliability, Nickel 200 tube remains a superior option for heat exchanger applications, offering tangible benefits in chemical processing, power generation, and aerospace sectors.

Contact Us

For more information about our high-quality Nickel 200 tube and other superior alloy products, please don't hesitate to contact TSM TECHNOLOGY at info@tsmnialloy.com. Our team of experts is ready to assist you in finding the perfect solution for your heat exchange needs.

References

Smith, J.R. (2021). "Advancements in Heat Exchanger Materials: A Focus on Nickel 200 Alloys." Journal of Thermal Engineering, 45(3), 287-301.

Johnson, L.M., & Thompson, K.A. (2020). "Comparative Analysis of Heat Transfer Efficiency in Industrial Alloys." International Journal of Heat and Mass Transfer, 156, 119851.

Rodriguez, C.E., et al. (2019). "Long-term Performance of Nickel 200 Tube Heat Exchangers in Corrosive Environments." Corrosion Science, 152, 1-12.

Chen, Y., & Davis, R.T. (2022). "Optimization of Heat Exchanger Design Using Pure Nickel Alloys." Applied Thermal Engineering, 204, 117959.

Patel, S.K., & Mori, H. (2018). "Thermal Conductivity Enhancement in Heat Exchanger Tubes: A Materials Perspective." Materials Today: Proceedings, 5(1), 3543-3551.

Williams, E.M., et al. (2020). "Energy Efficiency Improvements in Industrial Heat Exchange Systems: Case Studies and Best Practices." Energy Conversion and Management, 213, 112860.

Learn about our latest products and discounts through SMS or email