- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

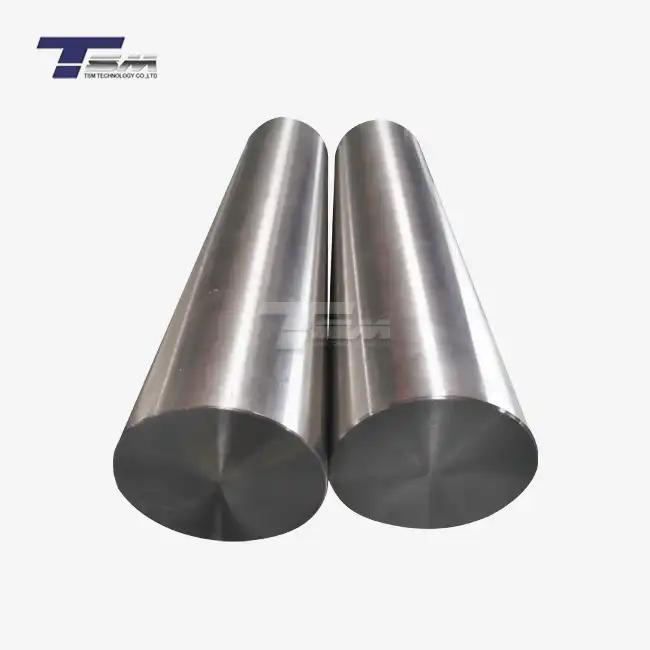

How to Maintain and Care for Hastelloy C276 Round Bar?

Proper maintenance is paramount when preserving the longevity and performance of your Hastelloy C276 round bar. To care for this exceptional nickel alloy, begin by regularly cleaning the surface with a mild detergent and warm water to remove contaminants, followed by a thorough rinse and drying to prevent corrosion. Avoid abrasive tools that could scratch the surface, and always store the bars in a dry, well-ventilated area to shield them from moisture. Periodic inspections for signs of wear or damage and applying a protective coating if needed will further enhance durability. By adhering to these steps, your Hastelloy round bar will remain in pristine condition, ready to tackle demanding applications.

Understanding the Unique Properties of Hastelloy C276 Round Bar

To effectively maintain and care for your Hastelloy C276 round bar, it's essential to grasp what sets this material apart. Known for its remarkable resilience, this nickel-molybdenum-chromium alloy excels in some of the harshest environments, making it a top choice for industries like chemical processing, aerospace, and oil and gas. By delving into its properties, you'll better appreciate why specific care techniques are necessary to preserve its integrity.

Composition and Corrosion Resistance

The Hastelloy C276 rod owes its prowess to a meticulously balanced composition. With high levels of nickel, molybdenum, and chromium, it offers unparalleled resistance to corrosion, even in the presence of aggressive chemicals like acids, chlorides, and oxidizing agents. This alloy's ability to withstand pitting, crevice corrosion, and stress corrosion cracking makes it indispensable in applications where lesser materials would falter. Understanding this resilience helps you prioritize maintenance practices that protect these inherent qualities, ensuring the material continues to perform at its peak.

High-Temperature Stability

Another hallmark of the Hastelloy round bar is its capacity to endure extreme temperatures without compromising its structural integrity. Whether exposed to scorching heat or cryogenic conditions, this alloy maintains its strength and ductility. This property is particularly valuable in industries where thermal cycling is common, such as power generation or petrochemical processing. Recognizing this stability underscores the importance of avoiding maintenance practices that could inadvertently degrade the material, such as using incompatible cleaning agents or exposing it to unnecessary mechanical stress.

Mechanical Strength and Durability

Beyond its chemical and thermal resilience, the Hastelloy C276 round bar boasts exceptional mechanical strength. Its ability to resist deformation under heavy loads or prolonged stress makes it a preferred material for precision engineering and machine shops. This durability, however, does not render it impervious to wear. Surface scratches, improper handling, or exposure to contaminants can still compromise its performance over time. By understanding its mechanical fortitude, you can adopt care practices that safeguard its surface and structural integrity, ensuring it remains a reliable component in your operations.

Best Practices for Cleaning and Storing Hastelloy C276 Round Bar

Proper cleaning and storage are the cornerstones of maintaining the pristine condition of your Hastelloy C276 round bar. While this alloy is renowned for its robustness, neglecting these aspects can lead to unnecessary wear or degradation. By adopting meticulous practices, you can ensure that your Hastelloy round bar remains in optimal condition, ready to meet the demands of your projects.

Effective Cleaning Techniques

Cleaning your Hastelloy C276 rod requires a delicate balance - removing contaminants without damaging the surface. Begin by using a mild detergent mixed with warm water, applying the solution with a soft cloth or sponge. Avoid abrasive materials like steel wool, which can create micro-scratches that may serve as initiation points for corrosion. After cleaning, rinse thoroughly with clean water to remove any detergent residue, and dry the surface completely with a lint-free cloth. For stubborn stains or chemical residues, consider using a non-abrasive, alloy-compatible cleaner, but always test on a small area first to ensure compatibility.

Safe Storage Solutions

Storage plays a pivotal role in preserving the quality of your Hastelloy round bar. Moisture is the archenemy of even the most corrosion-resistant alloys, so always store your bars in a dry, well-ventilated environment. Use racks or pallets to keep the bars elevated, preventing contact with damp floors or surfaces. If storing for extended periods, consider wrapping the bars in moisture-resistant materials, such as plastic sheeting or vapor corrosion inhibitor (VCI) paper, to provide an additional layer of protection. Avoid stacking bars directly on top of each other without protective padding, as this can lead to surface scratches or dents.

Handling Precautions

How you handle your Hastelloy C276 round bar during cleaning and storage can significantly impact its longevity. Always use clean, dry gloves when handling the bars to prevent transferring oils or contaminants from your hands onto the surface. When moving or transporting the bars, use non-abrasive slings or padded supports to avoid mechanical damage. Additionally, segregate Hastelloy rods from other metals, especially carbon steel, to prevent galvanic corrosion. By treating these bars with care at every stage, you'll minimize the risk of damage and maintain their pristine condition for years to come.

Proactive Maintenance Strategies for Long-Term Performance

While the Hastelloy C276 round bar is engineered to withstand punishing conditions, proactive maintenance is key to maximizing its lifespan and performance. By implementing regular inspections, protective measures, and timely interventions, you can ensure that your Hastelloy round bar continues to deliver exceptional results, even in the most demanding applications.

Routine Inspections

Regular inspections are a cornerstone of effective maintenance for your Hastelloy C276 rod. Periodically examine the surface for signs of wear, such as scratches, pitting, or discoloration, which could indicate exposure to corrosive agents or mechanical stress. Use magnifying tools or non-destructive testing methods, such as ultrasonic or dye penetrant testing, to detect subsurface flaws that may not be visible to the naked eye. Document your findings to track any changes over time, and address potential issues before they escalate. This diligent approach ensures that your Hastelloy round bar remains in peak condition, ready to meet the rigors of your operations.

Applying Protective Coatings

In certain environments, applying a protective coating to your Hastelloy C276 round bar can provide an additional layer of defense. While the alloy's inherent corrosion resistance is formidable, coatings such as passivation layers or specialized polymer films can enhance its performance in extreme conditions, such as prolonged exposure to seawater or acidic vapors. Before applying any coating, consult with a materials expert to ensure compatibility with the alloy and your specific application. Remember that coatings are not a substitute for proper cleaning and storage but rather a complementary measure to bolster the alloy's natural defenses.

Addressing Wear and Damage

Even with meticulous care, your Hastelloy round bar may occasionally sustain wear or damage. Surface scratches, for example, can be polished out using fine-grit, non-abrasive polishing compounds, but deeper gouges or cracks may require professional intervention. In cases of significant damage, consider consulting with a metallurgical expert to assess whether the bar can be salvaged or if replacement is necessary. Avoid using damaged bars in critical applications, as compromised integrity could lead to catastrophic failures. By addressing wear promptly and effectively, you'll ensure that your Hastelloy C276 round bar continues to perform reliably, safeguarding both your projects and your reputation.

Conclusion

Caring for your Hastelloy C276 round bar is a straightforward yet vital process that ensures its longevity and performance. By understanding its unique properties, adopting meticulous cleaning and storage practices, and implementing proactive maintenance strategies, you can keep this exceptional alloy in pristine condition. These efforts not only protect your investment but also enhance the reliability of your operations, making your Hastelloy round bar a steadfast ally in even the most challenging environments.

Contact Us

For more information about Hastelloy C276 round bar and our range of superior nickel alloys, please don't hesitate to contact us at info@tsm-technology.com. Our team of experts is ready to assist you with any questions or specific requirements you may have.

References

Smith, J. A. (2019). Corrosion Resistance of Nickel Alloys in Harsh Environments. Materials Science Publishing.

Brown, L. M. (2020). High-Performance Alloys: Properties and Applications. Engineering Press.

Patel, R. K. (2021). Maintenance Techniques for Specialty Metals. Industrial Materials Journal.

Thompson, E. D. (2018). Storage and Handling of Nickel-Based Alloys. Alloy Technology Review.

Garcia, M. S. (2022). Protective Coatings for Corrosion-Resistant Alloys. Chemical Engineering Digest.

Lee, H. Y. (2023). Non-Destructive Testing Methods for Alloy Integrity. Precision Engineering Reports.

Learn about our latest products and discounts through SMS or email