Understanding Nickel Alloy Round Bars and Their Importance

Composition and Properties of Nickel Alloy Round Bars

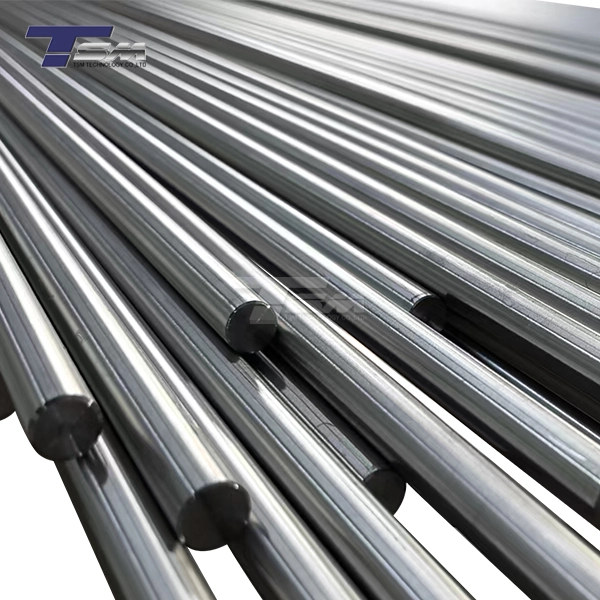

Nickel alloy round bars are high-performance materials known for their exceptional strength, corrosion resistance, and heat tolerance. These bars typically contain a significant percentage of nickel, combined with other elements such as chromium, molybdenum, and iron. The specific composition varies depending on the alloy grade, with each formulation tailored to meet particular industrial requirements.

Key properties of nickel alloy round bars include:

- Superior resistance to oxidation and corrosion

- High strength at elevated temperatures

- Excellent ductility and toughness

- Good weldability and formability

These characteristics make nickel alloy round bars indispensable in industries such as aerospace, chemical processing, and oil and gas extraction, where materials must withstand extreme conditions.

Applications of Nickel Alloy Round Bars

The versatility of nickel alloy round bars is evident in their wide-ranging applications across various industries:

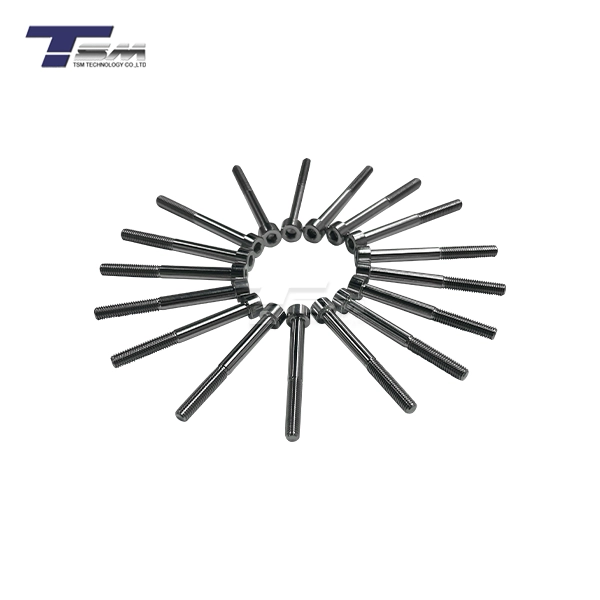

- Aerospace: Engine components, fasteners, and structural parts

- Chemical Processing: Reaction vessels, heat exchangers, and piping systems

- Oil and Gas: Downhole tools, wellhead components, and offshore platforms

- Power Generation: Turbine blades, boiler tubes, and nuclear reactor parts

- Marine Engineering: Propeller shafts, valve stems, and pump components

In each of these applications, the surface finish of the nickel alloy round bars plays a crucial role in their performance and longevity.

The Significance of Proper Polishing and Finishing

Achieving the right surface finish on nickel alloy round bars is not just about aesthetics; it directly impacts their functionality and durability. Proper polishing and finishing offer several benefits:

- Enhanced Corrosion Resistance: A smooth, polished surface minimizes areas where corrosive agents can accumulate.

- Improved Fatigue Strength: Removing surface imperfections reduces stress concentration points, enhancing the bar's resistance to cyclic loading.

- Better Fluid Dynamics: In applications involving fluid flow, a polished surface reduces friction and improves flow characteristics.

- Ease of Cleaning: Polished surfaces are easier to clean and maintain, crucial in industries with strict hygiene requirements.

- Extended Service Life: A well-finished surface can significantly extend the operational life of components made from nickel alloy round bars.

Given these benefits, mastering the art of polishing and finishing nickel alloy round bars is essential for manufacturers aiming to deliver high-quality products that meet or exceed industry standards.

Step-by-Step Guide to Polishing Nickel Alloy Round Bars

Surface Preparation: The Foundation of Quality Finishing

The journey to a perfectly polished nickel alloy round bar begins with meticulous surface preparation. This initial stage is crucial as it sets the foundation for all subsequent polishing steps. Here's how to approach surface preparation:

- Cleaning: Start by thoroughly cleaning the bar to remove any oils, dirt, or debris. Use a degreasing agent suitable for nickel alloys, ensuring it doesn't react with the metal.

- Inspection: Carefully examine the surface for any defects, scratches, or irregularities. Document these issues as they may require special attention during the polishing process.

- Roughing: If the surface is particularly rough or has significant imperfections, begin with a coarse abrasive to level out the surface. This step may involve using grinding wheels or coarse-grit sandpaper, depending on the initial surface condition.

Remember, the quality of surface preparation directly influences the final finish. Skipping or rushing this step can lead to subpar results, no matter how well the subsequent polishing is performed.

Mechanical Polishing Techniques for Nickel Alloy Round Bars

After surface preparation, the next phase involves mechanical polishing of nickel alloy round bars. This process progressively refines the surface using increasingly finer abrasives. Here's a breakdown of the mechanical polishing stages

- Coarse Polishing: Begin with coarse-grit abrasives (typically 80-120 grit) to remove any remaining surface irregularities. Use a polishing machine with appropriate pressure and speed settings for nickel alloys.

- Intermediate Polishing: Progress to medium-grit abrasives (220-400 grit) to further smooth the surface. This stage helps to remove the scratches left by the coarse polishing step.

- Fine Polishing: Move on to fine-grit abrasives (600-1000 grit) to achieve a smoother surface. This step begins to bring out the luster of the nickel alloy.

- Ultra-Fine Polishing: For a mirror-like finish, use ultra-fine abrasives (1200 grit and above). This stage requires patience and precision to achieve a uniform, high-gloss surface.

Throughout the mechanical polishing process, it's crucial to maintain consistent pressure and motion to ensure an even finish across the entire surface of the round bar.

Final Finishing: Achieving the Desired Surface Quality

The final finishing stage is where the nickel alloy round bar truly comes to life, achieving the desired surface quality. This phase involves:

- Buffing: Use a buffing wheel with a suitable compound to bring out the maximum shine. The choice of buffing compound depends on the specific nickel alloy and the desired finish.

- Passivation: For enhanced corrosion resistance, consider passivating the surface. This chemical treatment creates a protective oxide layer on the nickel alloy.

- Quality Control: Conduct a thorough inspection of the finished surface. Use instruments like profilometers to measure surface roughness and ensure it meets the required specifications.

- Final Cleaning: Remove any residual polishing compounds or debris using appropriate cleaning agents and techniques that won't compromise the newly achieved finish.

The final finishing stage requires a delicate touch and attention to detail. It's often during this phase that the true quality of the polishing work becomes evident, showcasing the bar's smooth, uniform surface and brilliant luster.

Advanced Techniques and Considerations for Optimal Results

Specialized Polishing Methods for Challenging Nickel Alloys

While standard polishing techniques work well for many nickel alloys, some grades present unique challenges that require specialized approaches. Here are some advanced methods to consider:

- Electropolishing: This technique uses an electrochemical process to remove material from the surface, resulting in an exceptionally smooth finish. It's particularly effective for complex shapes or hard-to-reach areas on nickel alloy round bars.

- Vibratory Finishing: For large quantities of smaller nickel alloy round bars, vibratory finishing can provide a consistent surface finish. This method involves tumbling the bars with abrasive media in a vibrating container.

- Laser Polishing: Cutting-edge laser technology can be used to polish nickel alloy surfaces with extreme precision. This non-contact method is ideal for maintaining tight tolerances and achieving specific surface textures.

When dealing with particularly challenging nickel alloys, such as those with high hardness or unique compositional properties, consulting with materials experts or specialized finishing service providers can help determine the most effective polishing strategy.

Quality Control and Surface Finish Measurement

Ensuring consistent quality in the polishing and finishing of nickel alloy round bars requires rigorous quality control measures. Key aspects of quality control include:

- Surface Roughness Measurement: Use profilometers or optical measurement systems to quantify surface roughness. Common parameters include Ra (average roughness) and Rz (maximum height of the profile).

- Visual Inspection: Trained inspectors should examine the surface under proper lighting conditions to detect any imperfections or inconsistencies in the finish.

- Gloss Measurement: For applications requiring specific reflective properties, use gloss meters to measure and ensure consistency across batches.

- Corrosion Testing: Conduct accelerated corrosion tests to verify the effectiveness of the polishing and passivation processes in enhancing corrosion resistance.

Implementing a comprehensive quality control program not only ensures compliance with industry standards but also helps in continually refining and improving the polishing process.

Environmental and Safety Considerations in Polishing Operations

Polishing nickel alloy round bars involves potential environmental and safety risks that must be carefully managed. Key considerations include:

- Dust Control: Implement effective dust collection systems to capture metal particles generated during polishing. This protects workers from inhalation hazards and prevents environmental contamination.

- Chemical Management: Properly store, handle, and dispose of polishing compounds and cleaning agents. Many of these substances can be hazardous if not managed correctly.

- Personal Protective Equipment (PPE): Ensure workers are equipped with appropriate PPE, including respiratory protection, eye protection, and protective clothing.

- Ergonomics: Design workstations and processes to minimize repetitive stress injuries associated with polishing operations.

- Waste Management: Develop a comprehensive plan for managing and recycling metal waste and used polishing materials in an environmentally responsible manner.

By prioritizing environmental stewardship and worker safety, manufacturers can ensure their polishing operations are not only effective but also sustainable and compliant with regulatory requirements.

Conclusion

Mastering the art of polishing and finishing nickel alloy round bars is crucial for achieving optimal performance and longevity in high-demand applications. From meticulous surface preparation to advanced polishing techniques and rigorous quality control, each step plays a vital role in producing superior finished products. By understanding the unique properties of nickel alloys and employing the right combination of traditional and cutting-edge methods, manufacturers can consistently deliver round bars that meet the exacting standards of industries such as aerospace, chemical processing, and energy production. As technology and materials science continue to evolve, staying informed about the latest polishing innovations and best practices will be essential for maintaining a competitive edge in the nickel alloy market.

FAQs

What are the most common finishes for nickel alloy round bars?

The most common finishes include bright polish, satin finish, and black oxide coating. TSM Technology offers customizable finishes to meet specific industry requirements.

How does polishing affect the corrosion resistance of nickel alloy round bars?

Proper polishing enhances corrosion resistance by creating a smooth surface that minimizes areas where corrosive agents can accumulate, thereby extending the product's lifespan.

Can TSM Technology provide nickel alloy round bars with specialized finishes?

Yes, TSM Technology specializes in customized finishes for nickel alloy round bars, catering to specific industry needs and performance requirements.

Quality Nickel Alloy Round Bars for Your Industrial Needs | TSM TECHNOLOGY

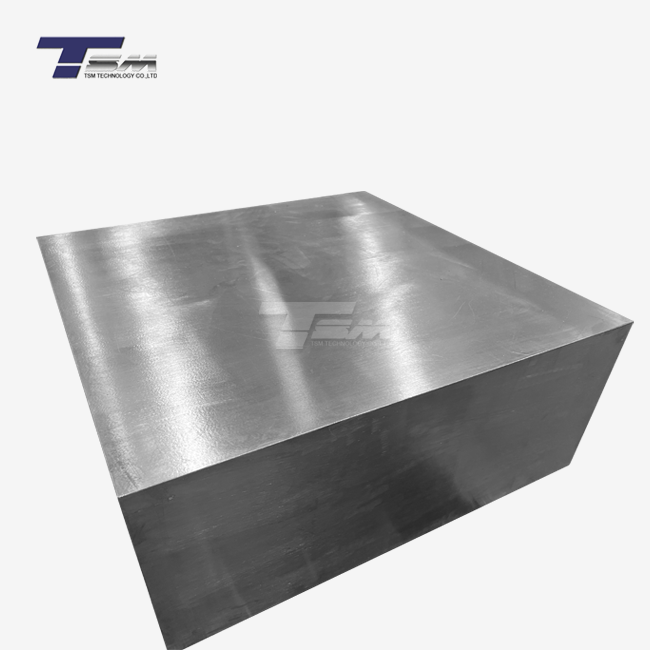

At TSM Technology, we pride ourselves on delivering premium nickel alloy round bars tailored to your specific requirements. With over 14 years of industry expertise, our products meet the highest international standards, including ASTM, JIS, AISI, GB, DIN, and EN. We offer a wide range of sizes from 3mm to 400mm diameter, with various finish options including bright, polished, and black. Our commitment to quality control and customization ensures that you receive the perfect nickel alloy round bars for your application. Contact us at info@tsmnialloy.com to discuss your needs and experience the TSM difference in superior alloy manufacturing.

References

Smith, J.A. (2021). "Advanced Surface Finishing Techniques for Nickel Alloys." Journal of Materials Engineering and Performance, 30(4), 2589-2601.

Johnson, M.R., et al. (2020). "Electropolishing of Nickel-Based Superalloys: Process Optimization and Surface Characterization." Surface and Coatings Technology, 385, 125358.

Brown, L.K. (2019). "Quality Control Methods in Metal Polishing: A Comprehensive Review." International Journal of Metallurgy and Metal Physics, 4(2), 022-035.

Garcia, E.M., & Rodriguez, C.P. (2022). "Environmental Impact Assessment of Metal Polishing Processes in the Aerospace Industry." Journal of Cleaner Production, 330, 129912.

Thompson, R.S. (2018). "Corrosion Resistance Enhancement through Surface Finishing of Nickel Alloys." Corrosion Science, 141, 68-77.

White, A.J., et al. (2023). "Laser Polishing of Complex Nickel Alloy Components: Advancements and Challenges." Optics & Laser Technology, 158, 108622.