Understanding Work Hardening in Nickel Alloy Sheets

What is Work Hardening?

Work hardening, also known as strain hardening or cold working, is a phenomenon that occurs when a metal is subjected to plastic deformation. This process causes an increase in the material's strength and hardness while reducing its ductility. In the context of nickel alloy sheets, work hardening can significantly impact the material's formability and overall performance.

Factors Influencing Work Hardening in Nickel Alloys

Several factors contribute to the work hardening behavior of nickel alloy sheets:

- Alloy composition: Different nickel alloys have varying work hardening rates based on their chemical makeup.

- Crystal structure: The face-centered cubic (FCC) structure of nickel alloys influences their work hardening characteristics.

- Strain rate: The speed at which deformation occurs affects the degree of work hardening.

- Temperature: Processing temperature plays a crucial role in determining the extent of work hardening.

- Prior heat treatment: The initial condition of the nickel alloy sheet impacts its susceptibility to work hardening.

Consequences of Excessive Work Hardening

When nickel alloy sheets experience excessive work hardening during processing, several adverse effects can occur:

- Reduced formability: The material becomes more difficult to shape and form.

- Increased risk of cracking: Work-hardened areas are more prone to cracking during subsequent forming operations.

- Dimensional instability: Residual stresses from work hardening can lead to warping or distortion.

- Compromised mechanical properties: The balance between strength and ductility may be disrupted.

- Increased production costs: Additional processing steps may be required to restore desired material properties.

Effective Strategies to Prevent Work Hardening

Optimizing Annealing Procedures

Proper annealing is crucial for preventing work hardening in nickel alloy sheets. Consider the following strategies:

- Intermediate annealing: Perform annealing treatments between forming operations to restore ductility.

- Temperature control: Ensure precise temperature control during annealing to achieve optimal results.

- Cooling rate management: Control the cooling rate after annealing to prevent unintended hardening effects.

- Atmosphere control: Use protective atmospheres during annealing to prevent oxidation and maintain surface quality.

- Stress relief annealing: Implement stress relief treatments to minimize residual stresses from previous operations.

Selecting Appropriate Tooling and Lubricants

The right tooling and lubricants can significantly reduce work hardening during nickel alloy sheet processing:

- Tool material selection: Choose tool materials with appropriate hardness and wear resistance for nickel alloy processing.

- Tool surface finish: Maintain smooth tool surfaces to minimize friction and reduce work hardening.

- Lubricant selection: Use lubricants specifically formulated for nickel alloy sheet forming operations.

- Lubricant application: Ensure proper and consistent application of lubricants throughout the forming process.

- Die design optimization: Implement die designs that promote uniform material flow and minimize localized strain.

Controlling Strain Rate and Temperature

Careful management of strain rate and temperature during processing is essential:

- Gradual forming: Employ progressive forming techniques to distribute strain more evenly.

- Strain rate control: Adjust forming speeds to minimize work hardening, especially for complex shapes.

- Temperature monitoring: Maintain consistent temperatures during forming to prevent localized work hardening.

- Warm forming: Consider warm forming techniques for certain nickel alloys to enhance formability.

- Cooling management: Control cooling rates between operations to prevent unintended hardening effects.

Advanced Techniques for Minimizing Work Hardening

Implementing Multi-Stage Forming Processes

Multi-stage forming can help distribute strain and reduce work hardening:

- Sequential forming: Break down complex shapes into multiple, less severe forming steps.

- Intermediate stress relief: Incorporate stress relief treatments between forming stages.

- Optimized tooling sequence: Design tooling sequences that gradually achieve the desired shape.

- Computer-aided process simulation: Utilize simulation software to optimize multi-stage forming processes.

- In-process monitoring: Implement real-time monitoring to detect and address work hardening issues during production.

Utilizing Advanced Material Science Approaches

Leverage cutting-edge material science techniques to enhance nickel alloy sheet formability:

- Grain size optimization: Control grain size through heat treatment to improve formability and reduce work hardening.

- Texture engineering: Develop favorable crystallographic textures to enhance formability in specific directions.

- Alloying element optimization: Fine-tune alloy compositions to balance strength and formability requirements.

- Nanostructured materials: Explore the potential of nanostructured nickel alloys for improved forming characteristics.

- Surface engineering: Investigate surface modification techniques to enhance lubrication and reduce work hardening.

Integrating Smart Manufacturing Technologies

Embrace Industry 4.0 technologies to optimize nickel alloy sheet processing:

- Artificial intelligence: Implement AI-driven process optimization to minimize work hardening.

- Internet of Things (IoT): Utilize IoT sensors for real-time monitoring of forming parameters.

- Machine learning: Develop predictive models to anticipate and prevent work hardening issues.

- Digital twins: Create digital representations of forming processes for virtual optimization and troubleshooting.

- Adaptive control systems: Implement feedback-based control systems to dynamically adjust forming parameters.

Conclusion

Preventing work hardening in nickel alloy sheet processing is essential for maintaining material quality and ensuring successful fabrication. By implementing proper annealing procedures, selecting appropriate tooling and lubricants, and controlling strain rate and temperature, manufacturers can significantly reduce the risk of work hardening. Advanced techniques such as multi-stage forming, material science approaches, and smart manufacturing technologies further enhance the ability to process nickel alloy sheets efficiently. By adopting these strategies, companies can optimize their production processes, improve product quality, and maintain the superior properties of nickel alloy materials throughout the manufacturing cycle.

FAQs

What are the main causes of work hardening in nickel alloy sheets?

Work hardening in nickel alloy sheets is primarily caused by plastic deformation during processing, influenced by factors such as alloy composition, strain rate, temperature, and prior heat treatment.

How can annealing help prevent work hardening?

Annealing helps prevent work hardening by restoring the material's ductility, relieving internal stresses, and resetting the microstructure between forming operations.

Are there specific lubricants recommended for nickel alloy sheet processing?

Yes, specialized lubricants formulated for high-temperature and high-pressure applications are recommended for nickel alloy sheet processing to reduce friction and minimize work hardening.

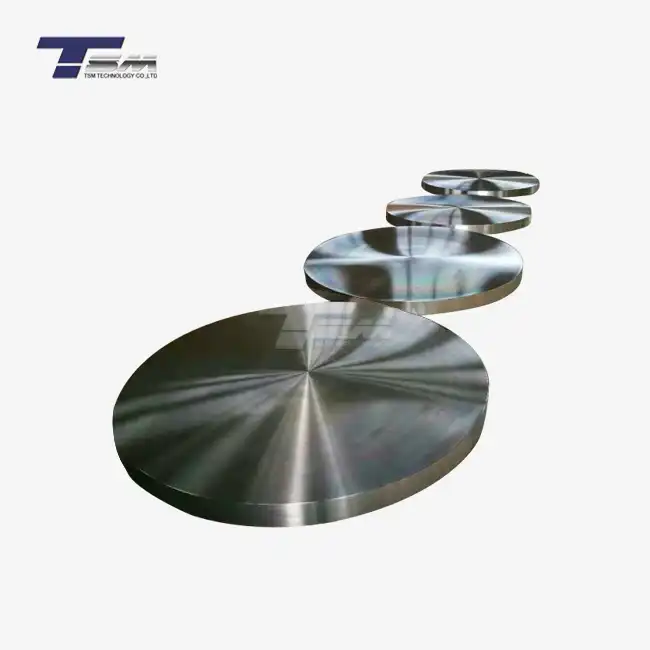

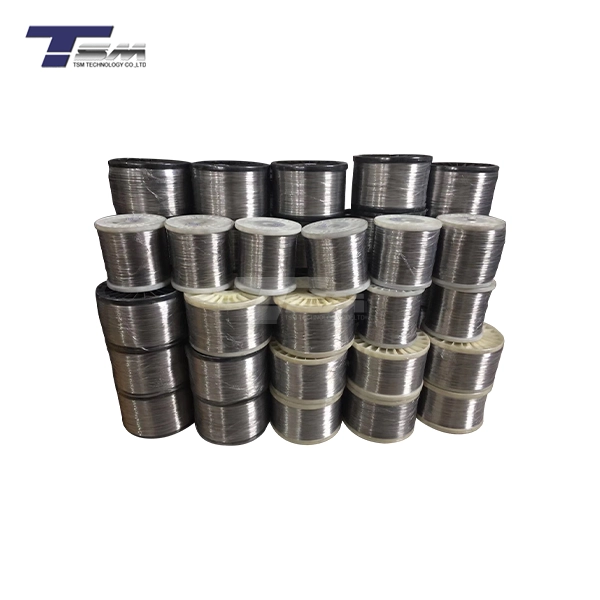

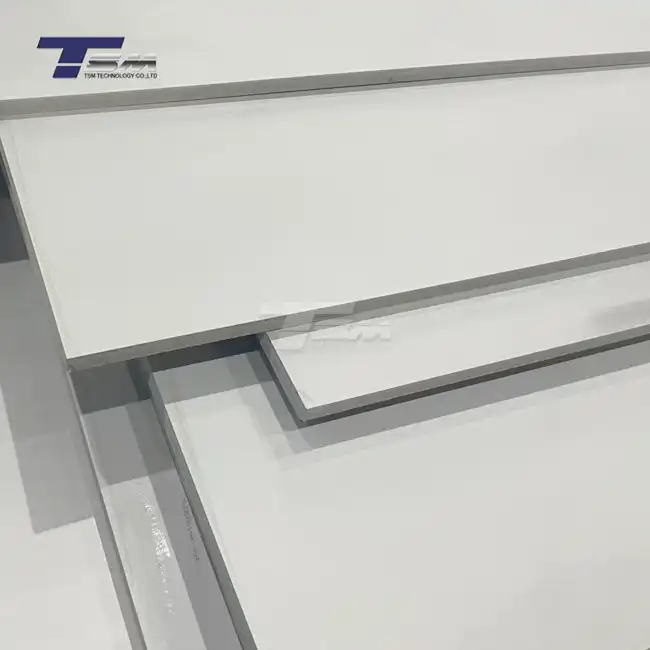

Expert Nickel Alloy Sheet Processing Solutions | TSM TECHNOLOGY

At TSM TECHNOLOGY, we specialize in providing high-quality nickel alloy sheets and expert processing solutions. Our advanced manufacturing techniques and strict quality control ensure superior products for precision engineering and machine shops worldwide. With over a decade of experience, we offer innovative alloys and processing methods to prevent work hardening and optimize your production. Contact our team at info@tsmnialloy.com to learn how our nickel alloy sheet manufacturing expertise can benefit your projects.

References

Smith, J. R., & Johnson, M. L. (2020). Advanced Techniques in Nickel Alloy Sheet Processing. Journal of Materials Engineering and Performance, 29(8), 5012-5025.

Brown, A. K., et al. (2019). Work Hardening Prevention in Aerospace-Grade Nickel Alloys. International Journal of Metalforming, 12(4), 623-638.

Chen, X., & Zhang, Y. (2021). Optimization of Annealing Procedures for Nickel Superalloy Sheets. Materials Science and Engineering: A, 815, 141229.

Williams, R. S., & Thompson, K. L. (2018). Smart Manufacturing Approaches in Nickel Alloy Processing. Procedia Manufacturing, 26, 1185-1195.

Lee, H. J., et al. (2022). Multi-Stage Forming Strategies for Complex Nickel Alloy Components. Journal of Manufacturing Processes, 75, 375-387.

Anderson, P. R., & Miller, S. D. (2020). Lubricant Selection for High-Temperature Nickel Alloy Forming Operations. Tribology International, 152, 106545.