- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

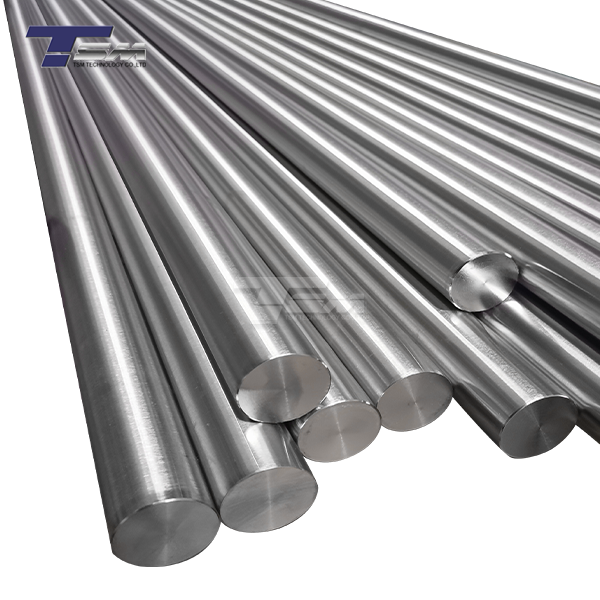

Inconel 600 Round Bar: Properties, Benefits and Applications

Are you searching for a material that excels in extreme environments, offering unparalleled durability and versatility? Look no further than the Inconel 600 round bar. Renowned for its exceptional properties, this nickel-chromium alloy delivers remarkable resistance to corrosion, oxidation, and high temperatures, making it a top choice across industries. Its benefits include longevity, adaptability, and cost-effectiveness, ensuring it meets the demands of precision engineering and machine shops globally. From aerospace components to chemical processing equipment, the applications of Inconel 600 bar are vast and varied, providing solutions where other materials falter. At TSM TECHNOLOGY, we pride ourselves on supplying superior alloys like alloy 600 round bar, meticulously inspected to meet the highest standards, ensuring reliability in every project.

Unveiling the Properties of Inconel 600 Round Bar

The allure of Inconel 600 round bar lies in its unique composition and the extraordinary characteristics it imparts. Understanding these properties is key to appreciating why this material is a cornerstone in demanding industries.

Composition and Structure

At its core, the Inconel 600 bar is a nickel-chromium alloy, with nickel constituting approximately 72% of its makeup, chromium around 14-17%, and iron contributing 6-10%. This precise blend, often enhanced with trace elements, creates a robust matrix that withstands aggressive environments. The face-centered cubic crystal structure of alloy 600 round bar ensures stability, even under thermal cycling, making it a paragon of resilience in high-stress applications.

Resistance to Corrosion and Oxidation

One of the standout traits of Inconel 600 round bar is its formidable resistance to corrosion and oxidation. Whether exposed to caustic chemicals, saline solutions, or oxidizing acids, this alloy remains unscathed, preserving its integrity over extended periods. Its chromium content forms a passive oxide layer, acting as a bulwark against degradation, particularly in high-temperature settings where other materials succumb to scaling or pitting.

High-Temperature Performance

The ability of Inconel 600 bar to perform under extreme heat is nothing short of remarkable. Capable of withstanding temperatures up to 2000°F (1093°C) without losing its mechanical strength, this alloy is a stalwart in environments where thermal stability is non-negotiable. Its low thermal expansion coefficient further enhances its suitability for applications involving rapid temperature fluctuations, ensuring dimensional stability and reducing the risk of warping or cracking.

Exploring the Benefits of Inconel 600 Round Bar

Beyond its intrinsic properties, the Inconel 600 round bar offers a plethora of advantages that make it indispensable in precision engineering and beyond. These benefits translate into tangible value, enhancing performance and longevity in critical applications.

Durability and Longevity

The Inconel 600 bar is synonymous with endurance. Its ability to resist corrosion, oxidation, and thermal degradation ensures a prolonged service life, even in the most arduous conditions. This durability reduces the need for frequent replacements, offering a cost-effective solution for industries where downtime is a costly affair. Components crafted from alloy 600 round bar maintain their structural integrity, delivering consistent performance over decades.

Versatility Across Industries

The adaptability of Inconel 600 round bar is a key reason for its widespread adoption. Its unique combination of properties allows it to serve a diverse array of sectors, from aerospace to marine engineering. Whether it's fashioned into fasteners, shafts, or heat exchanger tubes, this alloy proves its mettle in applications requiring precision and reliability. Its non-magnetic nature further broadens its utility, particularly in electronic and medical equipment where magnetic interference is a concern.

Cost-Effectiveness in the Long Run

While the initial investment in Inconel 600 bar may be higher than that of conventional materials, its long-term value is undeniable. The alloy's resistance to wear and tear, coupled with its minimal maintenance requirements, translates into significant savings over time. Industries that prioritize lifecycle costs over upfront expenses find alloy 600 round bar to be an economical choice, especially in applications where failure is not an option.

Applications of Inconel 600 Round Bar in Modern Industries

The true testament to the prowess of Inconel 600 round bar lies in its extensive range of applications. From the depths of the ocean to the vastness of space, this alloy plays a pivotal role in advancing technology and engineering.

Aerospace and Defense

In the aerospace sector, where materials must endure extreme temperatures and corrosive environments, Inconel 600 bar shines. It is commonly used in turbine blades, exhaust nozzles, and combustion chambers, where its ability to maintain strength at elevated temperatures is crucial. The alloy's resistance to stress-corrosion cracking also makes it a preferred choice for critical defense components, ensuring reliability in mission-critical scenarios.

Chemical and Petrochemical Processing

The chemical industry demands materials that can withstand aggressive substances and high temperatures, and alloy 600 round bar delivers on both fronts. It is widely utilized in heat exchangers, reactor vessels, and piping systems, where it resists attack from acids, alkalis, and other corrosive agents. Its stability in reducing and oxidizing environments makes it an ideal candidate for handling volatile chemicals, ensuring safety and efficiency in processing plants.

Energy and Power Generation

In the realm of energy production, Inconel 600 round bar is a linchpin in both conventional and renewable systems. It is employed in nuclear reactors, where its resistance to radiation and corrosion is vital, as well as in gas turbines and solar thermal systems, where high-temperature performance is paramount. The alloy's ability to endure thermal cycling without compromising its mechanical properties makes it indispensable in power generation facilities, contributing to the reliability and sustainability of energy infrastructure.

Conclusion

The Inconel 600 round bar stands as a paragon of engineering excellence, blending exceptional properties, myriad benefits, and versatile applications. Its ability to thrive in extreme conditions, coupled with its durability and cost-effectiveness, makes it a cornerstone in industries ranging from aerospace to energy. At TSM TECHNOLOGY, we are committed to delivering superior alloys like Inconel 600 bar, meticulously inspected to meet the highest standards, ensuring your projects achieve unparalleled performance and longevity.

Contact Us

Ready to elevate your engineering solutions with top-tier Inconel 600 round bar? Contact us today at info@tsmnialloy.com to learn more about our premium alloy offerings and how we can support your global projects.

References

Special Metals Corporation. "Inconel Alloy 600: Technical Data Sheet." Special Metals Corporation, 2020.

ASM International. "Properties and Selection: Nonferrous Alloys and Special-Purpose Materials." ASM Handbook, Volume 2, 1990.

Nickel Institute. "High-Performance Alloys for Resistance to Aqueous Corrosion." Nickel Institute Publication, 2018.

International Nickel Company. "Nickel Alloys in Aerospace Applications." Technical Bulletin, 2015.

Chemical Processing Magazine. "Material Selection for Corrosive Environments." Industry Report, 2019.

Energy Materials Society. "Advanced Alloys in Power Generation Systems." Conference Proceedings, 2021.

Learn about our latest products and discounts through SMS or email