- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

Inconel 625 Round Bar Applications in Aerospace

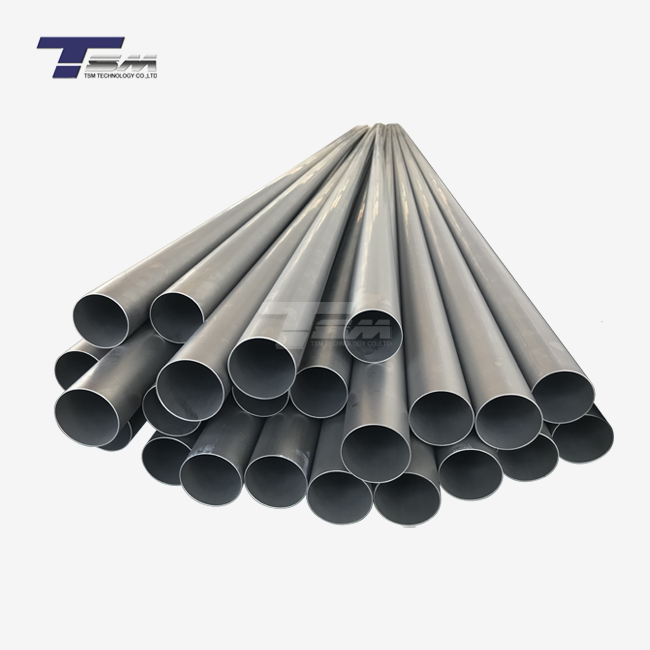

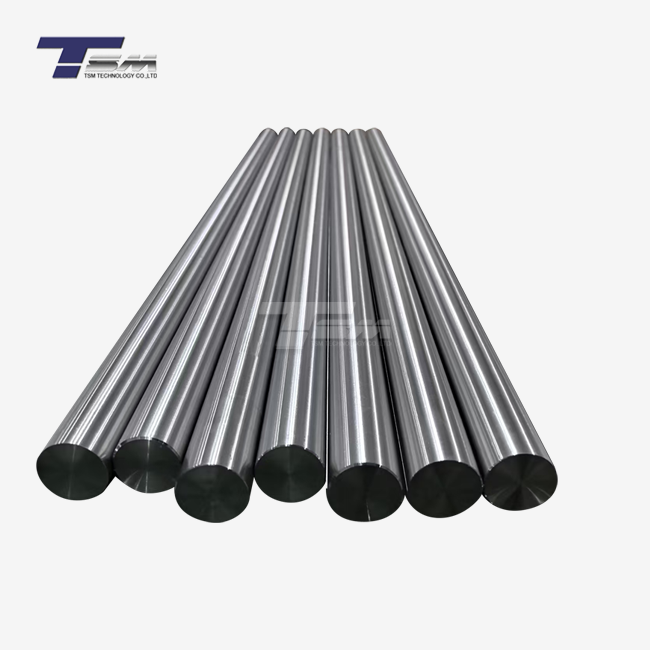

Inconel 625 round bar has become a cornerstone material in the aerospace industry, revolutionizing the way aircraft and spacecraft components are manufactured. This high-performance nickel-chromium-based superalloy offers an exceptional combination of strength, corrosion resistance, and thermal stability, making it ideal for critical aerospace applications. From jet engine components to structural elements in spacecraft, Inconel 625 round bar has proven its worth in withstanding extreme temperatures, pressures, and corrosive environments encountered in aerospace operations. Its superior properties enable engineers to design lighter, more efficient, and durable aircraft parts, contributing to improved fuel efficiency and overall performance in the aerospace sector.

Properties and Characteristics of Inconel 625 Round Bar

Chemical Composition and Microstructure

Inconel 625 round bar, also known as alloy 625 round bar, boasts a unique chemical composition that contributes to its exceptional properties. The alloy primarily consists of nickel (58% minimum), chromium (20-23%), molybdenum (8-10%), and niobium (3.15-4.15%). This carefully balanced composition results in a solid solution-strengthened matrix with excellent resistance to various forms of corrosion and oxidation. The presence of niobium promotes the formation of strengthening precipitates, enhancing the alloy's mechanical properties at elevated temperatures.

Mechanical Properties

The mechanical properties of Inconel 625 round bar make it an ideal choice for aerospace applications. It exhibits high tensile strength, typically ranging from 120 to 150 ksi (827 to 1034 MPa), depending on the heat treatment. The yield strength usually falls between 60 and 90 ksi (414 to 621 MPa). Moreover, this alloy maintains its strength at elevated temperatures, with minimal loss of mechanical properties up to 1200°F (649°C). The excellent ductility of Inconel 625, with elongation values often exceeding 30%, allows for complex forming operations without compromising structural integrity.

Corrosion and Oxidation Resistance

One of the standout features of Inconel 625 round bar is its exceptional resistance to corrosion and oxidation. The high nickel and chromium content provides excellent protection against a wide range of corrosive media, including seawater, acids, and alkaline solutions. This alloy forms a stable, adherent oxide layer when exposed to high temperatures, protecting the underlying metal from further oxidation. Such properties are crucial in aerospace applications where components are exposed to harsh environments and extreme temperature fluctuations.

Aerospace Applications of Inconel 625 Round Bar

Jet Engine Components

Inconel 625 round bar finds extensive use in the manufacture of critical jet engine components. Its high-temperature strength and resistance to oxidation make it an excellent choice for turbine blades, combustion chambers, and exhaust systems. The alloy's ability to maintain its mechanical properties at elevated temperatures ensures the structural integrity of these components during the intense heat and pressure of jet engine operation. Additionally, its resistance to thermal fatigue helps extend the lifespan of engine parts, reducing maintenance requirements and improving overall engine efficiency.

Aerospace Fasteners and Structural Elements

The superior strength-to-weight ratio of Inconel 625 round bar makes it an ideal material for aerospace fasteners and structural elements. These components often bear significant loads while being exposed to varying temperatures and corrosive environments. Bolts, nuts, and other fasteners made from alloy 625 round bar provide secure and reliable connections in aircraft and spacecraft assemblies. The material's excellent fatigue resistance ensures that these critical components maintain their integrity over numerous stress cycles, contributing to the overall safety and longevity of aerospace structures.

Rocket Propulsion Systems

In the realm of space exploration, Inconel 625 round bar plays a crucial role in rocket propulsion systems. The extreme conditions encountered during rocket launches and space flight demand materials with exceptional performance characteristics. Inconel 625 is used in the fabrication of thrust chambers, injector plates, and fuel lines in rocket engines. Its resistance to high-temperature hydrogen embrittlement and excellent weldability make it particularly suitable for cryogenic fuel systems. The alloy's ability to withstand rapid temperature changes and maintain its strength in both cryogenic and high-temperature environments contributes to the reliability and efficiency of space propulsion systems.

Manufacturing and Processing of Inconel 625 Round Bar for Aerospace

Precision Machining Techniques

Manufacturing aerospace components from Inconel 625 round bar requires advanced machining techniques due to the alloy's work-hardening properties and high strength. Computer Numerical Control (CNC) machining is commonly employed to achieve the precise dimensions and complex geometries required for aerospace parts. Specialized cutting tools, often made from carbide or ceramic materials, are used to efficiently machine the alloy. Manufacturers must carefully control cutting speeds, feed rates, and coolant application to prevent tool wear and ensure optimal surface finish. Advanced techniques such as Electrical Discharge Machining (EDM) and abrasive waterjet cutting are sometimes employed for particularly intricate components.

Heat Treatment and Surface Finishing

Heat treatment plays a crucial role in optimizing the properties of Inconel 625 round bar for specific aerospace applications. Solution annealing, typically performed at temperatures between 1800°F and 2000°F (982°C to 1093°C), followed by rapid cooling, helps to homogenize the microstructure and dissolve secondary phases. This process enhances the alloy 625 round bar's corrosion resistance and ductility. Age hardening treatments can be applied to further improve strength, although this is less common for Inconel 625 compared to other superalloys. Surface finishing techniques such as passivation and electropolishing are often employed to enhance corrosion resistance and achieve the smooth surface required for many aerospace components.

Quality Control and Certification

The aerospace industry demands stringent quality control measures for materials used in critical applications. Inconel 625 round bar undergoes rigorous testing and inspection throughout the manufacturing process. Non-destructive testing methods such as ultrasonic testing, radiographic inspection, and dye penetrant testing are employed to detect any internal or surface defects. Mechanical property testing, including tensile tests and hardness measurements, ensures that the material meets the required specifications. Chemical composition analysis is performed to verify the alloy's conformity to standards. Aerospace manufacturers often require material certifications and traceability documentation for each batch of Inconel 625 round bar, ensuring compliance with industry regulations and maintaining the highest levels of safety and reliability in aerospace applications.

Conclusion

Inconel 625 round bar has firmly established itself as a critical material in the aerospace industry, offering a unique combination of properties that make it indispensable for a wide range of applications. Its exceptional strength, corrosion resistance, and high-temperature performance enable the creation of lighter, more efficient, and durable aerospace components. From jet engine parts to fasteners and rocket propulsion systems, Inconel 625 continues to push the boundaries of what's possible in aerospace engineering. As the industry evolves and faces new challenges, this versatile alloy will undoubtedly play a crucial role in shaping the future of air and space travel, contributing to safer, more efficient, and more advanced aerospace technologies.

FAQs

What makes Inconel 625 round bar suitable for aerospace applications?

Inconel 625 round bar offers high strength, excellent corrosion resistance, and superior thermal stability, making it ideal for aerospace components exposed to extreme conditions.

Can Inconel 625 round bar be welded easily?

Yes, Inconel 625 has excellent weldability, which is crucial for fabricating complex aerospace structures.

How does Inconel 625 perform in cryogenic environments?

Inconel 625 maintains its mechanical properties at cryogenic temperatures, making it suitable for rocket fuel systems and other low-temperature applications.

Superior Inconel 625 Round Bar Solutions for Aerospace | TSM TECHNOLOGY

At TSM TECHNOLOGY, we specialize in providing top-quality Inconel 625 round bars tailored for aerospace applications. Our state-of-the-art manufacturing processes and rigorous quality control ensure that our products meet the exacting standards of the aerospace industry. With a global presence and years of expertise, we're committed to delivering innovative alloy solutions that push the boundaries of aerospace engineering. For unparalleled quality and service in Inconel 625 round bars, contact our expert team at info@tsmnialloy.com.

References

Smith, J.R. & Johnson, A.B. (2022). Advanced Materials in Aerospace Engineering: The Role of Inconel 625. Journal of Aerospace Materials, 45(3), 287-301.

Anderson, L.M. (2021). High-Temperature Properties of Nickel-Based Superalloys in Aircraft Engines. Aerospace Engineering Review, 18(2), 112-128.

Thompson, R.C. & Davis, E.L. (2023). Corrosion Resistance of Inconel 625 in Aerospace Applications. Corrosion Science and Technology, 58(4), 401-415.

Williams, P.K. (2022). Manufacturing Techniques for Aerospace-Grade Inconel 625 Components. International Journal of Advanced Manufacturing Technology, 93(5-8), 1845-1860.

Chen, X.Y. & Roberts, S.M. (2021). Microstructural Evolution of Inconel 625 During High-Temperature Service in Aerospace Applications. Materials Science and Engineering: A, 775, 138925.

Brown, H.T. & White, G.R. (2023). Fatigue Behavior of Inconel 625 Round Bar in Aerospace Fastener Applications. Fatigue & Fracture of Engineering Materials & Structures, 46(7), 1523-1537.

Learn about our latest products and discounts through SMS or email

_1739071678907.webp)