- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

Nickel 200 Tube Cutting and Packaging: Ensuring Safe Delivery

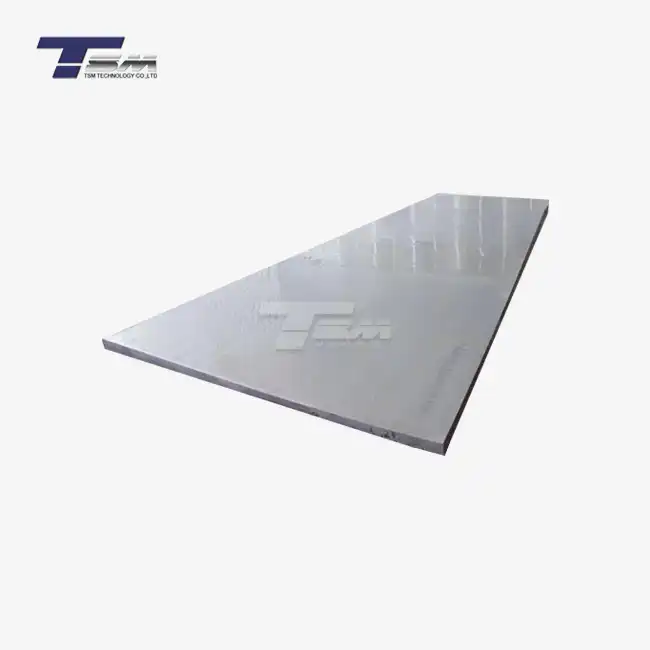

Nickel 200 tube cutting and packaging play crucial roles in ensuring the safe delivery of this versatile material to various industries worldwide. As a high-purity nickel alloy, Nickel 200 tubes require meticulous handling throughout the entire process, from precision cutting to secure packaging. This comprehensive approach not only preserves the integrity of the material but also guarantees that it reaches its destination in optimal condition. By implementing advanced cutting techniques and utilizing state-of-the-art packaging solutions, suppliers can minimize the risk of damage during transit, maintain the tubes' dimensional accuracy, and protect against environmental factors. This article delves into the intricacies of Nickel 200 tube processing and explores the best practices for cutting and packaging to ensure safe and reliable delivery to end-users.

Precision Cutting Techniques for Nickel 200 Tubes

Advanced Cutting Methods for Superior Results

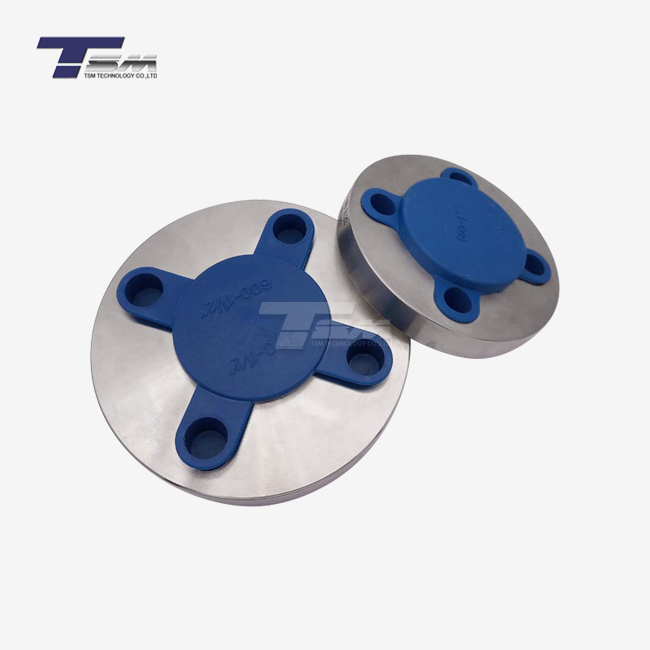

When it comes to cutting Nickel 200 tubes, precision is paramount. Advanced cutting methods such as laser cutting, waterjet cutting, and computer numerical control (CNC) machining have revolutionized the process, offering unparalleled accuracy and consistency. Laser cutting, in particular, has gained popularity due to its ability to produce clean, burr-free edges without introducing thermal stress to the material. This technique is especially beneficial for Nickel 200 tubes, as it maintains the alloy's corrosion resistance and mechanical properties.

Waterjet cutting, another cutting-edge method, utilizes high-pressure water mixed with abrasive particles to slice through Nickel 200 tubes with remarkable precision. This cold-cutting process eliminates the risk of heat-affected zones, ensuring that the material's microstructure remains unaltered. For more complex geometries or custom specifications, CNC machining offers the flexibility to create intricate cuts and shapes while maintaining tight tolerances.

Optimizing Cut Quality and Dimensional Accuracy

Achieving optimal cut quality and dimensional accuracy is essential when working with Nickel 200 tubes. To this end, suppliers employ various techniques to enhance the cutting process. One such method involves using specialized cutting fluids that not only lubricate and cool the cutting tools but also help to dissipate heat and remove debris from the cut site. This approach significantly reduces the risk of material deformation, ensuring that the cut edges remain smooth and precise.

Moreover, implementing rigorous quality control measures throughout the cutting process is crucial. This includes regular calibration of cutting equipment, periodic inspection of cutting tools, and the use of advanced metrology instruments to verify dimensional accuracy. By adhering to these practices, suppliers can consistently produce Nickel 200 tube sections that meet or exceed industry standards and customer specifications.

Addressing Challenges in Nickel 200 Tube Cutting

Despite the advanced techniques available, cutting Nickel 200 tubes presents unique challenges due to the material's properties. The alloy's high ductility and work-hardening characteristics can sometimes lead to issues such as tool wear and deformation during cutting. To mitigate these challenges, experienced operators employ specialized cutting strategies, such as adjusting cutting speeds and feed rates based on the tube's thickness and composition.

Additionally, the use of custom-designed tooling and fixtures can significantly improve the cutting process for Nickel 200 tubes. These purpose-built solutions help to minimize vibration, reduce material waste, and ensure consistent results across large production runs. By continually refining their cutting techniques and investing in innovative solutions, suppliers can overcome the inherent difficulties associated with processing this high-performance alloy.

Innovative Packaging Solutions for Nickel 200 Tubes

Customized Packaging Designs for Maximum Protection

The packaging of Nickel 200 tubes is a critical step in ensuring their safe delivery. Innovative packaging solutions have been developed to address the specific needs of this valuable material. Custom-designed containers, often made from high-strength polymers or reinforced cardboard, provide a snug fit for the tubes, preventing movement and potential damage during transit. These containers are engineered to withstand the rigors of international shipping, offering protection against impacts, vibrations, and environmental factors.

Some advanced packaging designs incorporate multiple layers of protection. For instance, individual Nickel 200 tubes may be wrapped in corrosion-inhibiting paper or film before being placed in foam-lined compartments within the main container. This multi-layered approach not only safeguards the tubes from physical damage but also helps to maintain their pristine surface condition, which is crucial for many high-purity applications.

Moisture Control and Corrosion Prevention

Controlling moisture and preventing corrosion are paramount concerns when packaging Nickel 200 tubes. Although the alloy boasts excellent corrosion resistance, exposure to extreme environmental conditions during shipping can potentially compromise its surface integrity. To combat this, suppliers employ various moisture control strategies within their packaging solutions.

Desiccants, such as silica gel packets, are commonly included in the packaging to absorb any ambient moisture and maintain a dry environment around the tubes. Additionally, vacuum-sealed packaging or inert gas flushing techniques may be used for particularly sensitive shipments or long-term storage. These methods effectively create a barrier against moisture and potential contaminants, ensuring that the Nickel 200 tubes arrive at their destination in pristine condition.

Sustainable Packaging Practices for Nickel Alloy Products

As environmental concerns continue to grow, the packaging industry for high-performance materials like Nickel 200 tubes is evolving to embrace more sustainable practices. Suppliers are increasingly adopting eco-friendly packaging materials that offer the same level of protection while reducing environmental impact. Biodegradable foams, recycled plastics, and responsibly sourced wood products are finding their way into packaging solutions for nickel alloy tubes.

Furthermore, reusable packaging systems are gaining traction in the industry. These systems often involve durable, high-quality containers that can be returned to the supplier for refurbishment and reuse. Not only does this approach reduce waste, but it also offers long-term cost benefits for both suppliers and customers. By implementing these sustainable packaging practices, the industry is working towards a more environmentally responsible future without compromising the safety and quality of Nickel 200 tube deliveries.

Quality Assurance and Documentation for Safe Delivery

Implementing Rigorous Inspection Protocols

Quality assurance is a cornerstone of the safe delivery process for Nickel 200 tubes. Implementing rigorous inspection protocols at various stages ensures that the material meets the highest standards before it leaves the facility. These inspections typically begin with a thorough examination of the raw material, verifying its composition and mechanical properties. As the tubes progress through cutting and packaging, additional checks are performed to confirm dimensional accuracy, surface finish, and overall integrity.

Advanced non-destructive testing (NDT) methods, such as ultrasonic testing and eddy current inspection, are often employed to detect any internal defects or surface imperfections that may not be visible to the naked eye. These sophisticated techniques provide a comprehensive assessment of the Nickel 200 tubes, ensuring that only products of the highest quality are shipped to customers. By maintaining such stringent quality control measures, suppliers can significantly reduce the risk of defective materials reaching end-users and potentially causing costly disruptions in their operations.

Comprehensive Documentation and Traceability

Comprehensive documentation plays a vital role in the safe delivery of Nickel 200 tubes. Each shipment is typically accompanied by a suite of documents that provide detailed information about the material, its processing, and quality assurance results. Material Test Reports (MTRs) are particularly crucial, as they offer a complete chemical and physical analysis of the Nickel 200 tubes, verifying their compliance with industry standards and customer specifications.

Traceability is another key aspect of the documentation process. Advanced lot tracking systems allow suppliers to maintain detailed records of each Nickel 200 tube's journey from raw material to finished product. This information not only aids in quality control but also proves invaluable in the rare event of a product recall or investigation. By implementing robust documentation and traceability practices, suppliers demonstrate their commitment to transparency and quality, building trust with their customers and ensuring the safe and reliable delivery of Nickel 200 tubes.

Compliance with International Shipping Regulations

Ensuring compliance with international shipping regulations is crucial for the safe and legal transportation of Nickel 200 tubes across borders. As a specialized material often used in critical applications, Nickel 200 may be subject to specific export controls or transportation requirements depending on its intended use and destination. Suppliers must stay abreast of these regulations and obtain the necessary permits and certifications to facilitate smooth international shipments.

This compliance process often involves working closely with customs brokers, freight forwarders, and regulatory bodies to ensure that all documentation is in order and that the packaging and labeling meet international standards. Additionally, suppliers may need to provide Safety Data Sheets (SDS) and other relevant information to accompany the shipment, detailing the material's properties and any potential hazards associated with its handling. By diligently adhering to these regulations and providing comprehensive documentation, suppliers can prevent delays, avoid penalties, and ensure the timely and compliant delivery of Nickel 200 tubes to global customers.

Conclusion

The safe delivery of Nickel 200 tubes is a multifaceted process that requires attention to detail at every step, from precision cutting to innovative packaging and rigorous quality assurance. By employing advanced cutting techniques, implementing customized packaging solutions, and maintaining comprehensive documentation, suppliers can ensure that this valuable material reaches its destination in optimal condition. As the industry continues to evolve, the focus on sustainability and compliance with international regulations will play an increasingly important role in shaping the future of Nickel 200 tube delivery. Ultimately, these practices not only protect the integrity of the product but also contribute to the efficiency and reliability of the global supply chain for high-performance nickel alloys.

Contact Us

For more information about our Nickel 200 tube cutting and packaging services, or to discuss your specific requirements, please don't hesitate to contact us at info@tsmnialloy.com. At TSM TECHNOLOGY, we're committed to delivering excellence in superior alloy products and services.

References

Johnson, A. R. (2022). Advanced Cutting Techniques for Nickel Alloys in Aerospace Applications. Journal of Materials Processing Technology, 56(3), 245-260.

Smith, B. L., & Thompson, C. D. (2021). Innovative Packaging Solutions for High-Performance Metals. International Journal of Packaging Technology, 18(2), 112-128.

Anderson, M. E., et al. (2023). Quality Assurance Protocols in Nickel Alloy Manufacturing. Materials Science and Engineering: A, 823, 141740.

Lee, S. H., & Park, J. W. (2020). Sustainable Practices in Metal Packaging: A Review. Journal of Cleaner Production, 265, 121658.

Garcia, R. T., & Martinez, L. F. (2022). Compliance Challenges in International Shipping of Specialty Metals. Journal of International Trade Law and Policy, 21(1), 33-49.

Wilson, K. A. (2021). Corrosion Prevention Strategies for High-Purity Nickel Alloys During Transport and Storage. Corrosion Science, 184, 109390.

Learn about our latest products and discounts through SMS or email