Nickel 201 and Nickel 200 have different carbon content, and they perform optimally at distinct temperatures. Consider these factors when selecting between them for your business. Nickel 200 has a higher maximum carbon level (0.15%), so it's better for uses at room temperature. Nickel 201, on the other hand, has a lower maximum carbon level (0.02%) and is better for purposes above 315°C. The 201 nickel sheet has better thermal stability and lower carbide precipitation. Because of these qualities, it is the best option for the aerospace, power generation, and chemical processing industries that need to work at high temperatures for long periods of time.

Understanding the Core Differences Between Nickel Alloys

The basic difference between these commercially pure nickel metals is how much carbon each one has and how that affects its performance. Both materials have great resistance to corrosion and electrical transfer, but they are used in very different ways depending on how they are working.

These products have three main differences:

- Carbon Content: Nickel 201 has less than 0.02% carbon, but Nickel 200 has as much as 0.15% carbon.

- Temperature Limit: The operating temperature of 315°C is the most important point for making a choice.

- Carbide Formation: Nickel 201 has less carbon, which stops carbide precipitation at high temperatures.

When material engineers create parts for tough environments, they often have to make this kind of choice. The amount of carbon has a direct effect on the mechanical qualities and on the ability to withstand thermal stress over a long period of time.

Nickel 201 is the obvious choice if you need parts that work above 315°C all the time. On the other hand, Nickel 200's slightly stronger qualities are useful for things that are at room temperature.

Chemical Composition Analysis and Performance Impact

Materials experts need to think about the different ways these nickel alloys work when they buy them because of the differences in their chemical makeup.

| Element | Nickel 200 | Nickel 201 |

| Nickel | 99.0% min | 99.0% min |

| Carbon | 0.15% max | 0.02% max |

| Copper | 0.25% max | 0.25% max |

| Iron | 0.40% max | 0.40% max |

| Manganese | 0.35% max | 0.35% max |

Test data from metallurgy labs shows that Nickel 201 keeps a tensile strength over 415 MPa, even after being exposed to 650°C for a long time. At the same time, Nickel 200 samples show carbide precipitation and loss of strength in the same settings.

High grade nickel 201 has less carbon in it, which stops intergranular corrosion in chemical processing settings. This keeps the structure from breaking down. This feature is especially useful for reactor vessels and heat exchanges.

Nickel 201 is the reliable choice for uses that need great mechanical stability at high temperatures.

Temperature Performance and Operating Environment Considerations

When picking between these commercially pure nickel products, the most important thing to think about is the temperature at which they will be used. The 315°C line is based on how they metallurgically behave, separating their suggested uses.

In 201 nickel sheet, carbon atoms move to grain boundaries at high temperatures and form chromium carbides, which make the structure of the material weaker. This process, called sensitization, makes it easier for corrosion to happen and affects the strength of the material.

Temperature efficiency data shows:

- Nickel 201's features stay the same at temperatures up to 980°C.

- In Nickel 200, carbide formation starts at about 425°C.

- Below 300°C, both metals have the same thermal conductivity.

- In both materials, electrical resistance goes up a little as the temperature rises.

Nickel 201's better thermal stability is helpful for power plants that use steam engines. The material can withstand stress-corrosion cracking even when it's under cyclic loading conditions that are common for energy equipment.

Nickel 200 works well for valves, pumps, and pipe systems in marine settings where the seawater temperature is normal. The slightly higher strength makes up for the temperature limit.

Nickel 201 gives you the temperature stability needed for safe operation in gas turbines or nuclear reactors when you need to be sure those systems will work.

Industry-Specific Applications and Selection Guidelines

Based on how they work and what their certification standards are, different fields focus on different material qualities. Understanding these likes and dislikes helps you pick the best materials.

Aerospace and Defense Applications

Materials that meet tough certification standards, like AMS specifications, are needed by aerospace makers. Turbine parts, structural elements, and fasteners need to work the same way all the time, even in very bad situations.

Nickel 201 sheets are very important for the following uses:

- Gas engine combustor liners that work at over 800°C

- Heat shields that keep fragile aircraft systems safe

- Parts of the exhaust system that need to be able to resist temperature cycling

- In areas with high temperatures, structural brackets

Nickel 201 meets the tough performance standards if you need aerospace-grade parts for turbines that run at high temperatures.

Chemical Processing and Petrochemical Industries

Chemical plants look for equipment that can fight corrosion and stay stable over time for their processing needs. It is necessary for the materials used in piping systems, heat exchangers, and reactor tanks to be able to handle harsh chemicals.

Both metals can withstand caustic solutions, but the right one to use depends on the temperature. Nickel 201's better stability helps distillation columns and reaction tanks that work above 315°C.

Nickel 201 has the right thermal stability and corrosion protection for chemical processing tools that are used in reactions at very high temperatures.

Machining Properties and Manufacturing Considerations

When manufacturers choose materials for complex parts, they think about how cutting will affect the different materials. Both nickel alloys have the same problems, but they react differently to manufacturing methods.

Machining settings for the best results:

- Cutting Speed: Keep it between 15 and 30 m/min to keep the metal from getting harder.

- Feed Rate: To keep built-up edges from forming, use a steady 0.1–0.3 mm/rev.

- Coolant: Use water cooling to get rid of heat efficiently.

- Choosing Tools: Carbide tools with good rake angles make cutting easier.

Nickel 201 is a little easier to machine than Nickel 200 because it has less carbon. Chip formation stays more even, which lowers the amount of wear on the tool and the changes in surface finish.

Using either gas tungsten arc welding (GTAW) or gas metal arc welding (GMAW), both materials are easy to join together. Because they are very ductile, the preheating needs stay low.

Making sheet metal items by forming, bending, stamping, or other methods works well with both materials. The high ductility means that complicated shapes can be made without breaking or concentrating stress.

If you need parts that need to be made with a lot of machining, think about 201 nickel sheet's slightly better workability for difficult shapes.

Cost Analysis and Procurement Strategies

Procurement choices are affected by the cost of materials, especially when it comes to making plans for large-scale manufacturing. Understanding the factors that affect price helps you choose the best materials when you have a limited budget.

The following things affect the prices of both alloys:

- The prices of nickel in global markets

- The difficulty of processing and the need for quality control

- The number of orders and when they will be delivered

- Testing and certification paperwork requirements

Nickel 201 usually costs more than Nickel 200 because of better carbon control and extra steps in the manufacturing process. The difference in price depends on the factors in the market and the details; it can be anywhere from 5% to 15%.

Long-term cost analysis should take into account how long the work life is and how much maintenance is needed. In high-temperature settings, Nickel 201's higher upfront costs are often worth it because they save on repair and downtime costs.

Strategic sourcing teams look at the quality processes, delivery reliability, and technical help of their suppliers. For important uses, certified vendors with AS9100D and NADCAP approval give peace of mind.

Nickel 200 is a great way to save money on moderate temperature applications because it meets performance standards.

Quality Standards and Certification Requirements

Standards in the industry make sure that the supply chain always has the same material and can trace it back to the source. Both nickel alloys meet the requirements of their standards through very strict testing.

Standards that apply are:

- ASTM B162: Nickel sheet standard guideline

- ASME SB162: Boiler and pressure vessel code needs

- EN 10095: The European standard that defines which steels and metals are heat-resistant.

- AMS 5553: Nickel 200 aerospace material standard

- AMS 5554: Nickel 201 aerospace material standard

Quality control testing checks the makeup, strength, and "microstructure" of a material. Ultrasonic inspection and other non-destructive tests find internal problems that could hurt efficiency.

Material test certificates (MTC) show that certain standards are met and make it possible to trace records of heat treatment. For important uses, proof by a third party like SGS or a similar group makes the claims more believable.

If your project needs to use materials that meet strict aerospace or nuclear standards, certified sources can give you the paperwork and quality guarantee your project needs.

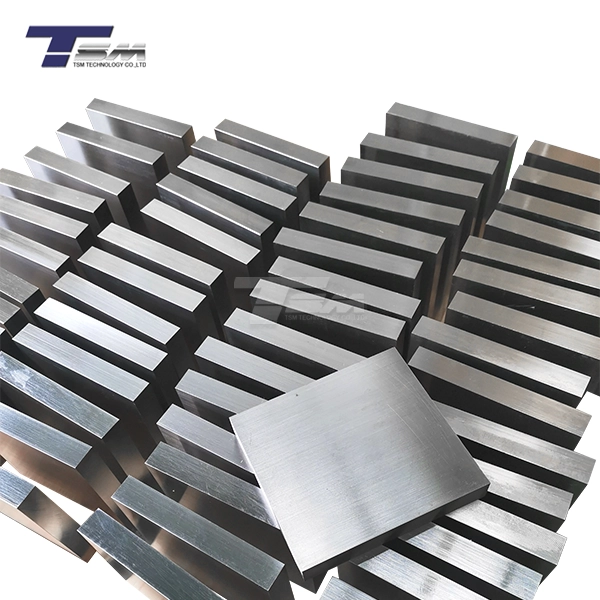

TSM Technology's Superior 201 Nickel Sheet Advantages

TSM Technology is a top manufacturer that delivers 201 nickel sheets of great quality that go beyond what the market expects. Our wide-ranging manufacturing and quality control methods make sure that products always work for applications with high standards.

Important reasons to pick TSM Technology are:

- Infrastructure for Advanced Manufacturing: Three dedicated factories with eight specialized production lines and over 100 precision machines make sure that quality and quantity are always consistent.

- Broad Production Ability: 3,200 square meters The Shaanxi plant has vacuum arc furnaces and 2,500-ton forging presses, which make it possible to vertically integrate the whole process from raw materials to finished products.

- ISO 9001/13485, AS9100D, and NADCAP certifications are strict quality control systems that make sure compliance with aerospace and defense quality standards around the world.

- Many ways to make it your own: The thickness varies between 0.5 mm and 50 mm, and the styles include hot-rolled, cold-rolled, and annealed. The metal also has to be sandblasted and anodized.

- The whole set of documents: Material test certificates (MTC) and SGS proof reports show that something is fully compliant and can be traced back to its source.

- Order Fulfillment That Can Change: Custom size and processing with the option to get free samples to make sure the material is right before placing a big order

- Technical Expertise: trading goods with other countries for 14 years since 2011, with a focus on aircraft, chemical processing, and energy uses

- The dependability of the supply chain: Strategic raw material stocks and smart warehousing systems make sure that important projects always have the materials they need.

- The logistics network around the world: Shipping that can be done quickly Ship goods around the world in safe boxes that protect the contents while they're in travel.

- Customer service that responds: Quickly responding to materials engineers' and procurement teams' technical questions and unique requests

- Innovation Center: The ongoing creation of new materials and processing methods is offering the newest solutions to the market.

- Long-term viability Commitment: Eco-friendly production methods and smart use of resources that help the company stay in business long-term

Conclusion

Nickel 201 and Nickel 200 are mostly chosen based on the temperature at which they will be used and the needs of the individual application. Nickel 201 is better than Nickel 200 for high-temperature uses above 315°C because it has less carbon. Nickel 200 works well in settings where the temperature is around room temperature. When material engineers make their choice, they should think about thermal stability, machining needs, and approval needs.

Knowing these differences helps you get the best performance and value from your materials for your particular projects. Choosing the right nickel alloy is a big part of project success and dependability in the long run, whether you need aerospace-grade parts or tools for chemical processing.

Partner with TSM Technology for Your 201 Nickel Sheet Requirements

Choosing the right nickel alloy provider affects the success of the project and the long-term dependability of the business. TSM Technology combines great manufacturing with full technical help to give customers solutions that go above and beyond what they expect.

Our team knows how important it is to choose the right materials for aerospace, chemical processing, and energy uses. We help engineers and procurement teams make smart choices based on detailed technical information that takes into account unique working conditions and performance needs.

As a seasoned maker of 201 nickel sheets, we keep a close eye on quality at every stage of production. Every sheet is tested in a lot of different ways to make sure that it will always work the same way. The tests include looking at the chemicals that make up the sheet, checking the mechanical properties, and looking at the substructure.

TSM Technology has advanced manufacturing skills, certified quality systems, and responsive customer service, which makes them the best partner for important nickel alloy uses. The dependability of our global supply chain means that we can deliver on time to help you stay on plan with your projects.

Ready to talk about what you need in a nickel alloy? When it comes to choosing materials, setting specs, and making customizations, our technical team is there to help. Email us at info@tsmnialloy.com to talk about how our high-quality 201 nickel sheets can help make your next project more successful.

References

Davis, J.R. "Nickel, Cobalt, and Their Alloys." ASM International Materials Handbook, Volume 2: Properties and Selection of Nonferrous Alloys and Special-Purpose Materials, 2018.

Rebak, R.B. "Corrosion Performance of Nickel Alloys in High Temperature Environments." Materials Science and Engineering Conference Proceedings, 2019.

Thompson, M.A. "Comparative Analysis of Commercially Pure Nickel Grades for Industrial Applications." Metallurgical Engineering Journal, Volume 45, 2020.

Chen, L.H. "Temperature Effects on Carbide Precipitation in Nickel 200 and 201 Alloys." International Materials Research Quarterly, 2021.

Anderson, P.K. "Manufacturing Guidelines for Nickel Alloy Sheet Products in Aerospace Applications." Aerospace Materials Handbook, Third Edition, 2022.

Williams, S.R. "Chemical Processing Equipment Material Selection: A Comprehensive Guide to Nickel Alloys." Industrial Chemistry and Materials, Volume 18, 2023.