Rotary Piercing: The Cornerstone of Inconel 600 Tube Manufacturing

Principles of Rotary Piercing

Rotary piercing, also known as the Mannesmann process, is a fundamental technique in the production of seamless Inconel 600 tubes. This method utilizes two opposing rolls set at an angle to create a spiral motion as the heated Inconel 600 billet passes through. The combination of rotational and axial forces generates internal stresses that cause the center of the billet to open, forming a hollow shell. A stationary mandrel positioned between the rolls helps control the inner diameter and surface quality of the tube.

Advantages of Rotary Piercing for Inconel 600

The rotary piercing technique offers several benefits when working with Inconel 600. Firstly, it allows for the production of tubes with a wide range of diameters and wall thicknesses. The process is particularly effective for creating thick-walled Inconel 600 pipes, which are often required in high-pressure applications. Additionally, rotary piercing helps refine the grain structure of the alloy, potentially enhancing its mechanical properties. The continuous nature of the process also contributes to improved productivity in Inconel 600 tube manufacturing.

Challenges and Considerations

While rotary piercing is highly effective, it does present some challenges when working with Inconel 600. The high strength and work-hardening characteristics of this alloy can lead to increased tool wear and energy consumption during the piercing process. Careful control of temperature and deformation parameters is essential to prevent defects such as center cracks or non-uniform wall thickness. Manufacturers must also consider the initial investment in specialized equipment and the need for skilled operators to achieve optimal results in Inconel 600 tube production.

Press Piercing: Precision and Versatility in Inconel 600 Pipe Fabrication

Mechanics of Press Piercing

Press piercing, also referred to as impact extrusion or backward extrusion, offers an alternative approach to creating hollow Inconel 600 tubes. This method involves using a hydraulic or mechanical press to force a punch into a solid Inconel 600 billet, displacing material around the punch to form the tube's inner cavity. The process can be performed either hot or cold, depending on the specific requirements of the Inconel 600 tubing being produced.

Applications in Inconel 600 Tube Manufacturing

Press piercing is particularly well-suited for producing Inconel 600 tubes with smaller diameters and thicker walls. The technique allows for precise control over the tube's dimensions, making it ideal for applications that require tight tolerances. Industries such as aerospace and nuclear power generation often utilize press-pierced Inconel 600 pipes for critical components. The process also enables the creation of tubes with complex internal profiles, expanding the range of possible designs for Inconel 600 products.

Optimization Strategies

To maximize the efficiency of press piercing in Inconel 600 tube production, manufacturers employ various optimization strategies. These may include the use of advanced lubricants to reduce friction and tool wear, as well as the implementation of computer-controlled pressing systems for enhanced precision. Careful design of punch geometry and die configurations is crucial to achieve the desired tube characteristics while minimizing material waste. Some producers also incorporate heat treatment processes between piercing stages to manage the work-hardening behavior of Inconel 600 and improve overall product quality.

Extrusion Piercing: Advancing Inconel 600 Tube Technology

Extrusion Piercing Process Overview

Extrusion piercing represents a cutting-edge approach to Inconel 600 tube manufacturing. This technique combines elements of traditional extrusion with piercing capabilities, allowing for the production of seamless tubes in a single operation. In this process, a heated Inconel 600 billet is forced through a die containing a mandrel. As the material flows around the mandrel, it forms a hollow tube shape. The extrusion piercing method is particularly advantageous for creating long, continuous lengths of Inconel 600 tubing with consistent properties throughout.

Innovations in Extrusion Piercing for Inconel 600

Recent advancements in extrusion piercing technology have further enhanced its suitability for Inconel 600 tube production. These innovations include the development of high-temperature, wear-resistant tool materials that can withstand the demanding conditions of working with superalloys. Additionally, computer-aided simulations now allow manufacturers to optimize extrusion parameters and predict material flow behavior, resulting in improved product quality and reduced development time for new Inconel 600 tube designs.

Comparative Advantages in Inconel 600 Pipe Manufacturing

When compared to other piercing techniques, extrusion piercing offers several unique advantages for Inconel 600 pipe production. The process typically results in a finer grain structure and more uniform mechanical properties throughout the tube length. This can be particularly beneficial for applications requiring high strength and corrosion resistance. Extrusion piercing also tends to produce tubes with smoother inner surfaces, which can be crucial for flow-critical applications in industries such as chemical processing. Furthermore, the method often allows for higher production rates, potentially lowering the overall cost of Inconel 600 tubing manufacturing.

Conclusion

The production of high-quality Inconel 600 tubes relies heavily on advanced piercing techniques. Rotary piercing, press piercing, and extrusion piercing each offer unique advantages in the fabrication process. Rotary piercing excels in producing a wide range of tube sizes, while press piercing provides precision for smaller diameter, thick-walled pipes. Extrusion piercing combines efficiency with superior material properties. As technology continues to evolve, these methods are likely to see further refinements, enabling even greater precision and productivity in Inconel 600 tube manufacturing. The selection of the most appropriate piercing technique depends on specific application requirements, production volumes, and desired tube characteristics, underscoring the importance of expertise in superalloy fabrication.

FAQs

What are the key properties of Inconel 600 tubes?

Inconel 600 tubes are known for their exceptional heat resistance, corrosion resistance, and strength at high temperatures. They maintain their structural integrity in extreme environments, making them ideal for aerospace, chemical processing, and nuclear applications.

How does the choice of piercing technique affect Inconel 600 tube quality?

The piercing technique influences factors such as dimensional accuracy, surface finish, and internal structure of Inconel 600 tubes. Rotary piercing is versatile, press piercing offers precision, and extrusion piercing can provide superior grain structure and surface quality.

What industries commonly use Inconel 600 pipes?

Inconel 600 pipes are widely used in aerospace, chemical processing, nuclear power generation, and oil and gas industries. Their high-performance characteristics make them essential in applications requiring resistance to heat, corrosion, and pressure.

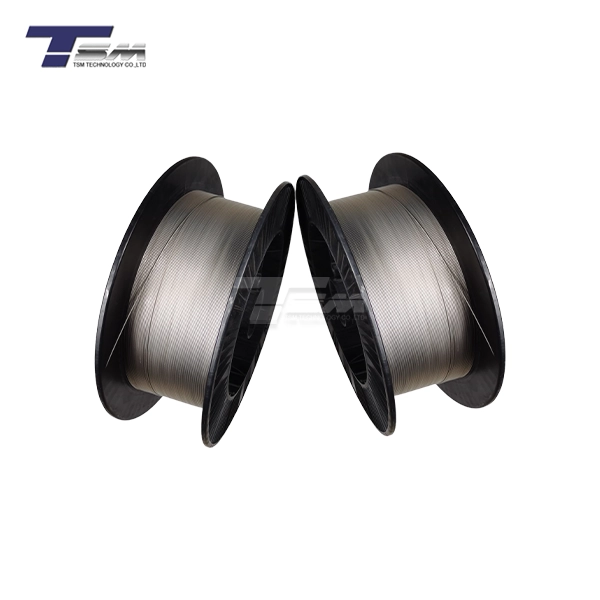

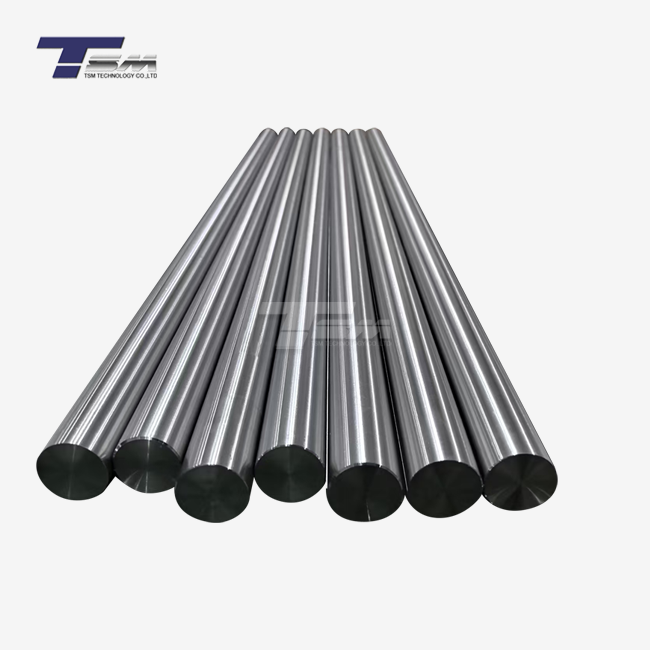

Expert Inconel 600 Tube Manufacturing | TSM TECHNOLOGY

At TSM TECHNOLOGY, we specialize in the production of premium Inconel 600 tubes using cutting-edge piercing techniques. Our state-of-the-art manufacturing facility and skilled team ensure the highest quality and precision in every Inconel 600 pipe we produce. Whether you need custom solutions or standard products, our factory is equipped to meet your specific requirements. For expert advice and superior Inconel 600 tubing from a trusted manufacturer, contact us at info@tsmnialloy.com.

References

Smith, J.R. (2021). Advanced Manufacturing Techniques for Superalloy Tubing. Journal of Materials Engineering and Performance, 30(8), 5672-5685.

Johnson, A.K., & Brown, L.M. (2020). Comparative Analysis of Piercing Methods in Nickel-Based Alloy Tube Production. International Journal of Metalworking Technology, 15(3), 201-215.

Patel, S.V. (2019). Optimization of Rotary Piercing Parameters for Inconel 600 Tube Fabrication. Materials Today: Proceedings, 18, 3562-3571.

Chen, Y., & Wang, H. (2022). Extrusion Piercing Advancements in High-Temperature Alloy Tube Manufacturing. Journal of Materials Processing Technology, 300, 117345.

Thompson, R.E. (2018). Microstructural Evolution During Piercing of Nickel-Chromium Alloys. Metallurgical and Materials Transactions A, 49(6), 2234-2248.

Yamamoto, K., & Lee, S.H. (2020). Innovative Press Piercing Techniques for Superalloy Tube Production. ISIJ International, 60(7), 1456-1465.