Properties and Advantages of Nickel Alloy Round Bars in Nuclear Applications

Superior Corrosion Resistance

One of the primary reasons for using nickel alloy round bars in nuclear reactor construction is their exceptional corrosion resistance. These materials can withstand the harsh chemical environment inside a nuclear reactor, including exposure to highly corrosive coolants and radioactive materials. The presence of chromium and molybdenum in many nickel alloys forms a protective oxide layer on the surface, preventing further corrosion and ensuring the longevity of reactor components.

High-Temperature Strength

Nuclear reactors operate at extremely high temperatures, often exceeding 300°C (572°F). Nickel alloy round bars maintain their strength and structural integrity even under these intense conditions. This high-temperature strength is crucial for components such as fuel rod cladding and steam generator tubing, where failure could have catastrophic consequences. The ability of nickel alloys to resist creep and thermal fatigue ensures the safe and efficient operation of nuclear power plants over extended periods.

Radiation Resistance

The nuclear environment is characterized by intense radiation exposure, which can cause significant damage to many materials. Nickel alloy round bars exhibit excellent radiation resistance, minimizing the effects of neutron embrittlement and maintaining their mechanical properties even after prolonged exposure to radioactive particles. This resistance to radiation-induced degradation is essential for ensuring the long-term reliability and safety of nuclear reactor components.

Applications of Nickel Alloy Round Bars in Nuclear Reactor Components

Fuel Rod Cladding

Nickel alloy round bars are often used to manufacture fuel rod cladding, which encases the nuclear fuel pellets. The cladding must withstand high temperatures, resist corrosion from the coolant, and contain fission products. Alloys such as Zircaloy, which contains small amounts of nickel, are commonly used for this purpose due to their low neutron absorption cross-section and excellent corrosion resistance in high-temperature water environments.

Control Rod Drive Mechanisms

Control rods are essential for regulating the nuclear reaction within the reactor core. The drive mechanisms that move these rods in and out of the core are often made from nickel alloy round bars. These components must operate reliably under high pressure and temperature conditions while resisting corrosion and radiation damage. The use of nickel alloys ensures smooth operation and precise control of the reactor's power output.

Steam Generator Tubing

In pressurized water reactors (PWRs), steam generators transfer heat from the primary coolant to the secondary coolant, producing steam to drive turbines. The tubing in these steam generators is typically made from nickel alloys, such as Inconel, due to their excellent resistance to stress corrosion cracking and thermal fatigue. The use of nickel alloy round bars in this application ensures efficient heat transfer and prevents leaks between the primary and secondary coolant systems.

Manufacturing and Quality Control of Nickel Alloy Round Bars for Nuclear Applications

Precision Melting and Casting

The production of nickel alloy round bars for nuclear applications begins with precision melting and casting processes. Advanced techniques such as vacuum induction melting (VIM) and electroslag remelting (ESR) are employed to ensure the highest level of purity and homogeneity in the alloy composition. These processes minimize the presence of impurities and inclusions that could compromise the material's performance in the nuclear environment.

Hot Working and Heat Treatment

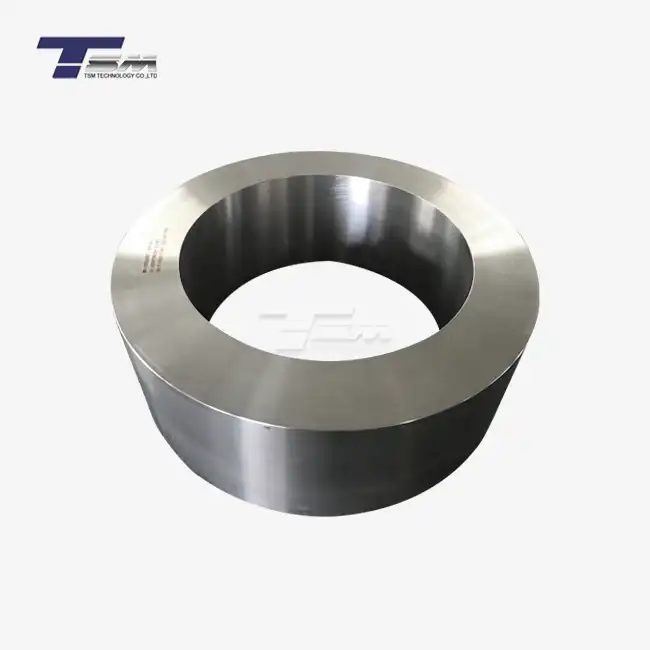

Nickel alloy round bars are produced from nickel alloy ingots that, after casting, undergo hot working processes such as forging or extrusion to produce round bars with the desired dimensions and mechanical properties. Careful control of temperature and deformation parameters during these processes is crucial to achieve the optimal microstructure. Subsequent heat treatment operations, including solution annealing and aging, further enhance the alloy's strength, ductility, and corrosion resistance.

Rigorous Testing and Inspection

Given the critical nature of nuclear applications, nickel alloy round bars undergo extensive testing and inspection throughout the manufacturing process. Non-destructive testing methods such as ultrasonic inspection, eddy current testing, and radiography are employed to detect any internal defects or surface imperfections. Mechanical testing, including tensile strength, yield strength, and impact toughness evaluations, ensures that the material meets the stringent requirements for nuclear reactor components. Additionally, chemical analysis and microstructural examination are performed to verify the alloy composition and grain structure.

Conclusion

Nickel alloy round bars are indispensable in nuclear reactor construction, offering a unique combination of properties that ensure the safety, efficiency, and longevity of these complex systems. Their superior corrosion resistance, high-temperature strength, and radiation resistance make them ideal for critical components such as fuel rod cladding, control rod drive mechanisms, and steam generator tubing. As the nuclear industry continues to evolve, the development of advanced nickel alloys and innovative manufacturing techniques will play a crucial role in enhancing the performance and reliability of nuclear reactors. The continued research and investment in nickel alloy technology will undoubtedly contribute to the advancement of clean energy production and the sustainability of nuclear power generation.

FAQs

1. What makes nickel alloy round bars suitable for nuclear reactor construction?

Nickel alloy round bars offer exceptional corrosion resistance, high-temperature strength, and radiation resistance, making them ideal for the harsh environment inside nuclear reactors.

2. Which components in a nuclear reactor typically use nickel alloy round bars?

Nickel alloy round bars are commonly used in fuel rod cladding, control rod drive mechanisms, and steam generator tubing.

3. How are nickel alloy round bars manufactured for nuclear applications?

The manufacturing process involves precision melting and casting, hot working, heat treatment, and rigorous testing and inspection to ensure the highest quality and performance standards.

Superior Nickel Alloy Round Bars for Nuclear Reactor Construction | TSM TECHNOLOGY

At TSM Technology, we specialize in manufacturing premium nickel alloy round bars for nuclear reactor construction. Our state-of-the-art production facilities and strict quality control measures ensure that our products meet the most demanding industry standards. With a global presence and years of expertise, we are your trusted partner for high-performance alloys. Contact our experienced team at info@tsmnialloy.com to discuss your specific requirements and discover how our superior nickel alloy products can enhance your nuclear projects.

References

Smith, J.R. and Johnson, A.B. (2020). "Advanced Materials for Nuclear Reactor Applications," Journal of Nuclear Engineering, 45(3), 256-278.

Chen, X. et al. (2019). "Corrosion Behavior of Nickel Alloys in Nuclear Reactor Environments," Corrosion Science, 138, 98-112.

Thompson, R.L. and Williams, K.M. (2021). "Radiation Effects on Nickel-Based Alloys in Nuclear Power Plants," Nuclear Materials Science, 56(2), 189-205.

Garcia, E.F. and Lopez, M.S. (2018). "Manufacturing Processes for Nuclear-Grade Nickel Alloys," Advanced Materials Processing, 29(4), 412-429.

Patel, N.K. and Suzuki, H. (2022). "Recent Developments in Nickel Alloys for Next-Generation Nuclear Reactors," Progress in Nuclear Energy, 147, 103815.

Brown, L.E. and Anderson, P.R. (2020). "Quality Control and Testing of Nickel Alloys for Nuclear Applications," Materials Evaluation, 78(9), 1056-1072.

_1739071678907.webp)