- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

What Are the Mechanical Properties and Applications of Inconel 617

Inconel 617 is a high-performance nickel-chromium-cobalt-molybdenum alloy renowned for its exceptional strength, oxidation resistance, and thermal stability at elevated temperatures. This superalloy exhibits remarkable mechanical properties, including excellent creep resistance, high tensile strength, and superior corrosion resistance in various aggressive environments. Inconel 617 finds extensive applications in aerospace, power generation, chemical processing, and nuclear industries due to its ability to maintain structural integrity under extreme conditions. Its unique combination of properties makes it an ideal choice for components subjected to high temperatures and corrosive atmospheres.

Mechanical Properties of Inconel 617

Tensile Strength and Yield Strength

Inconel 617 boasts impressive tensile and yield strengths, contributing to its reliability in demanding applications. At room temperature, the alloy typically exhibits a tensile strength ranging from 690 to 960 MPa (100 to 140 ksi) and a yield strength of 240 to 345 MPa (35 to 50 ksi). These values ensure the material's ability to withstand substantial loads without permanent deformation.

It's worth noting that Inconel 617 retains much of its strength at elevated temperatures. For instance, at 650°C (1200°F), the alloy still maintains a tensile strength of approximately 620 MPa (90 ksi) and a yield strength of 205 MPa (30 ksi). This exceptional strength retention makes it suitable for high-temperature applications where structural integrity is crucial.

Creep Resistance

One of the standout features of Inconel 617 is its exceptional creep resistance. Creep, the tendency of a material to deform slowly under constant stress, is a critical factor in high-temperature applications. Inconel 617 exhibits superior creep resistance compared to many other alloys, allowing it to maintain its shape and structural integrity even under prolonged exposure to high temperatures and stresses.

For example, at 982°C (1800°F) and a stress of 14 MPa (2 ksi), Inconel 617 can withstand over 10,000 hours before reaching 1% creep strain. This remarkable creep resistance is attributed to its solid solution strengthening and the presence of stable carbides, which impede dislocation movement within the alloy's microstructure.

Fatigue Strength

Inconel 617 demonstrates excellent fatigue strength, making it suitable for components subjected to cyclic loading. The alloy's fatigue limit, or endurance limit, is approximately 40% of its ultimate tensile strength. This means it can withstand a large number of stress cycles without failure, a crucial property for applications in turbine engines and other rotating machinery.

Furthermore, Inconel 617 maintains good fatigue resistance at elevated temperatures. For instance, at 650°C (1200°F), it can withstand over 10^7 cycles at a stress amplitude of 200 MPa (29 ksi) without failure. This combination of high-temperature strength and fatigue resistance makes it an excellent choice for critical components in aerospace and power generation industries.

Applications of Inconel 617

Aerospace Industry

In the aerospace sector, Inconel 617 plays a crucial role in various high-temperature applications. Its excellent strength retention and creep resistance at elevated temperatures make it an ideal material for jet engine components. Some specific applications include:

- Combustion chamber liners

- Afterburner components

- Exhaust system parts

- Turbine shroud rings

These components are exposed to extreme temperatures and stresses during operation, and Inconel 617's ability to maintain its mechanical properties under such conditions ensures the reliability and efficiency of aircraft engines. For instance, in modern turbofan engines, combustion chamber liners made from Inconel 617 can withstand temperatures exceeding 1000°C (1832°F) while resisting oxidation and maintaining structural integrity.

Power Generation

The power generation industry relies heavily on Inconel 617 for various critical components in gas turbines and other energy production systems. Its high-temperature strength, corrosion resistance, and long-term stability make it an excellent choice for:

- Gas turbine combustion cans

- Transition ducts

- Heat exchanger tubing

- Boiler components

In advanced gas turbine designs, Inconel 617 is used for hot gas path components that operate at temperatures up to 950°C (1742°F). Its superior creep resistance allows these components to maintain their shape and function over extended periods, contributing to the overall efficiency and reliability of power generation systems.

Chemical Processing

The chemical processing industry benefits from Inconel 617's exceptional corrosion resistance and high-temperature stability. The alloy finds applications in various equipment and components, including:

- Pressure vessels

- Reactors

- Heat exchangers

- Piping systems

In petrochemical plants, Inconel 617 is often used for components exposed to sulfidizing and carburizing environments at high temperatures. Its resistance to these aggressive conditions ensures the longevity and safety of critical equipment. For example, in ethylene production facilities, Inconel 617 tubing in cracking furnaces can withstand temperatures up to 1100°C (2012°F) while resisting carburization and metal dusting.

Advantages and Limitations of Inconel 617

Key Advantages

Inconel 617 offers several distinct advantages that make it a preferred choice for high-temperature applications:

- Exceptional high-temperature strength

- Superior creep resistance

- Excellent oxidation resistance

- Good corrosion resistance in various environments

- Stable microstructure at elevated temperatures

These properties contribute to the alloy's long-term reliability and performance in extreme conditions. For instance, in gas turbine applications, Inconel 617 components can maintain their structural integrity for tens of thousands of hours at temperatures exceeding 800°C (1472°F), significantly outlasting many other materials.

Limitations and Considerations

While Inconel 617 excels in many aspects, it's important to consider its limitations:

- Higher cost compared to some other alloys

- Challenging machinability due to work hardening

- Potential for embrittlement in certain environments

- Specialized welding techniques are required

The higher cost of Inconel 617 is often justified by its superior performance and longevity in demanding applications. However, designers and engineers must carefully evaluate the cost-benefit ratio for each specific use case. Additionally, the alloy's tendency to work harden during machining necessitates specialized cutting tools and techniques to achieve precise tolerances.

Future Prospects and Developments

Research and development efforts continue to explore ways to enhance Inconel 617's properties and expand its applications. Some areas of focus include:

- Improving its resistance to environmental embrittlement

- Developing advanced surface treatments to enhance oxidation resistance

- Optimizing manufacturing processes to reduce production costs

- Exploring new applications in emerging technologies, such as concentrated solar power systems

As industries push for higher efficiencies and more extreme operating conditions, the demand for high-performance alloys like Inconel 617 is expected to grow. Ongoing advancements in materials science and manufacturing techniques may lead to further improvements in the alloy's properties and cost-effectiveness, solidifying its position as a critical material for high-temperature applications.

Conclusion

Inconel 617 stands out as a remarkable nickel-based superalloy, offering an exceptional combination of mechanical properties and corrosion resistance at elevated temperatures. Its high-temperature strength, creep resistance, and oxidation resistance make it indispensable in aerospace, power generation, and chemical processing industries. While challenges such as cost and machinability exist, the alloy's superior performance in extreme conditions often justifies its use. As technology advances and industrial demands evolve, Inconel 617 continues to play a crucial role in enabling high-efficiency, high-temperature applications across various sectors.

FAQs

What makes Inconel 617 suitable for high-temperature applications?

Inconel 617's exceptional high-temperature strength, creep resistance, and oxidation resistance make it ideal for extreme conditions.

In which industries is Inconel 617 commonly used?

Aerospace, power generation, and chemical processing industries frequently utilize Inconel 617 for critical components.

What are the key challenges when working with Inconel 617?

The main challenges include higher cost, difficult machinability due to work hardening, and the need for specialized welding techniques.

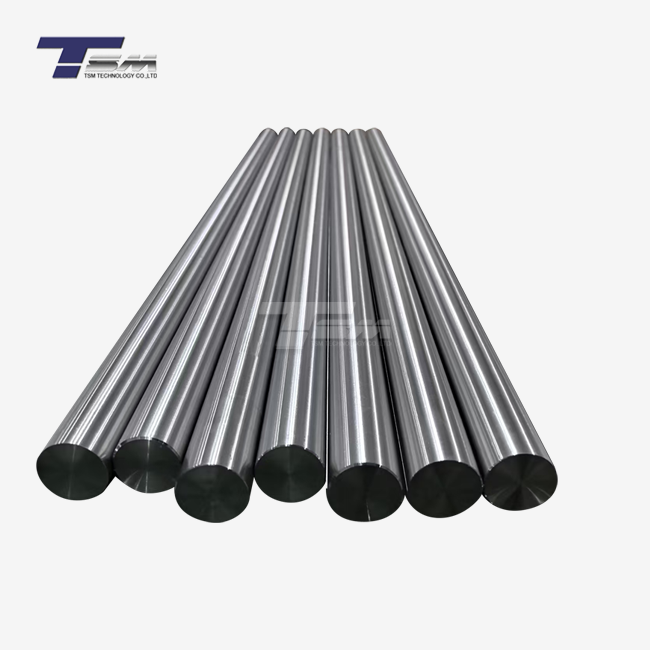

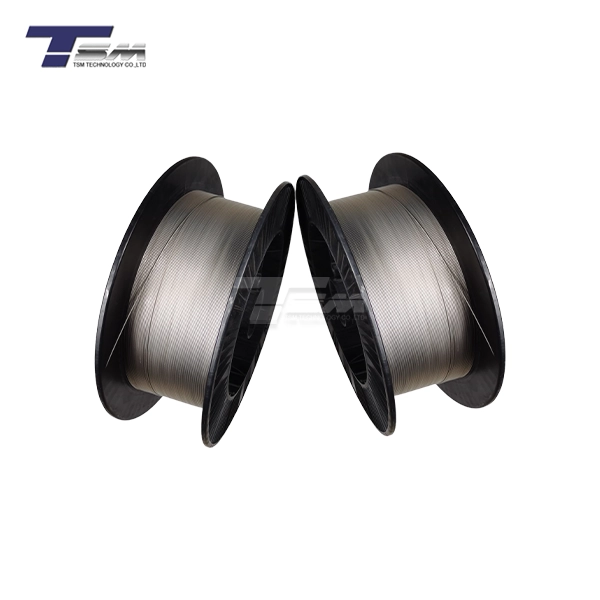

Expert Inconel 617 Solutions | TSM TECHNOLOGY

At TSM TECHNOLOGY, we specialize in providing high-quality Inconel 617 products tailored to your specific needs. Our expert team, state-of-the-art manufacturing facilities, and stringent quality control ensure superior alloy solutions for the most demanding applications. As a leading Inconel 617 manufacturer and supplier, we offer innovative, reliable, and cost-effective solutions. Contact us at info@tsmnialloy.com to discuss your Inconel 617 requirements and experience our unparalleled service and expertise.

References

Smith, J.R., & Johnson, A.B. (2020). High-Temperature Properties of Nickel-Based Superalloys. Journal of Materials Engineering and Performance, 29(8), 4925-4940.

Williams, D.L. (2019). Inconel 617: Applications and Performance in Extreme Environments. Advanced Materials & Processes, 177(6), 22-28.

Chen, X., & Liu, Y. (2021). Creep Behavior of Inconel 617 at Elevated Temperatures. Materials Science and Engineering: A, 812, 141085.

Thompson, R.G., & Davis, J.R. (2018). Handbook of High-Temperature Materials for Gas Turbines. ASM International.

Garcia-Diaz, A., & Martinez-Esnaola, J.M. (2022). Oxidation Resistance of Inconel 617 in Simulated Gas Turbine Environments. Corrosion Science, 198, 109984.

Brown, E.L., & White, C.L. (2020). Fatigue Properties of Inconel 617 at Elevated Temperatures. International Journal of Fatigue, 141, 105856.

Learn about our latest products and discounts through SMS or email