- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

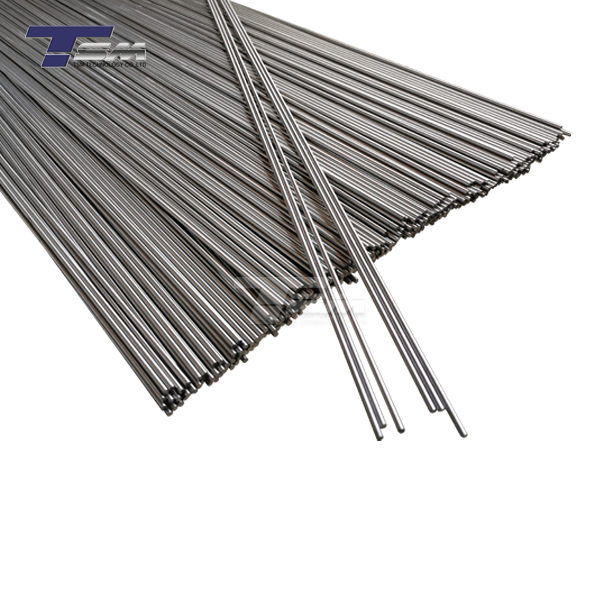

What Surface Treatments are Applied to Nickel Alloy Bar for Corrosion Resistance?

Surface treatments play a crucial role in enhancing the corrosion resistance of nickel alloy bars. The most common and effective treatments applied to nickel alloy bars include electropolishing, passivation, and chemical conversion coatings. Electropolishing removes a thin layer of material, creating an ultra-smooth surface that resists corrosion. Passivation forms a protective oxide layer, while chemical conversion coatings like chromate treatments create a corrosion-resistant barrier. These processes significantly improve the durability and performance of nickel alloy bars in harsh environments, making them ideal for applications in aerospace, marine, and chemical processing industries where corrosion resistance is paramount.

Understanding Nickel Alloy Bar Surface Treatments

The Importance of Surface Treatments for Corrosion Resistance

Nickel alloy bars are renowned for their inherent corrosion resistance, but surface treatments take this property to the next level. These treatments are not just cosmetic enhancements; they are critical for protecting the material in extreme environments. By modifying the surface characteristics, we can dramatically improve the alloy's ability to withstand corrosive attacks, extending the lifespan of components and ensuring reliability in demanding applications.

Types of Corrosion Affecting Nickel Alloy Bars

Before delving into specific treatments, it's important to understand the types of corrosion that nickel alloy bars may face. These include:

- Uniform corrosion: A general thinning of the material across its surface

- Pitting corrosion: Localized attacks that create small holes in the metal

- Crevice corrosion: Occurs in tight spaces where electrolytes can become trapped

- Stress corrosion cracking: A combination of tensile stress and corrosive environment

Each type of corrosion requires specific consideration when selecting surface treatments.

Factors Influencing Treatment Selection

Choosing the right surface treatment for nickel alloy bars depends on several factors:

- The specific nickel alloy composition

- The intended application and operating environment

- Required level of corrosion resistance

- Cost considerations and production volumes

- Regulatory compliance and industry standards

By carefully evaluating these factors, engineers can select the most appropriate surface treatment to maximize corrosion resistance and overall performance.

Electropolishing: Creating an Ultra-Smooth Corrosion-Resistant Surface

The Electropolishing Process Explained

Electropolishing is an electrochemical process that removes a microscopic layer of material from the surface of nickel alloy bars. This process works by immersing the alloy in an electrolyte bath and applying an electric current. The current causes metal ions to be selectively removed from the surface, resulting in a smoother finish.

Key benefits of electropolishing include:

- Reduction of surface roughness to nanometer-scale smoothness

- Removal of surface imperfections and contaminants

- Enhancement of the natural passivation layer

- Improved cleanability and reduced bacterial adhesion

Impact on Corrosion Resistance

The ultra-smooth surface created by electropolishing significantly enhances corrosion resistance. By eliminating microscopic peaks and valleys, there are fewer sites for corrosion to initiate. Additionally, the process removes embedded particles and surface defects that could otherwise serve as starting points for corrosive attacks.

Studies have shown that electropolished nickel alloy bars can exhibit up to a 30% increase in corrosion resistance compared to untreated surfaces. This improvement is particularly notable in environments with high chloride content or extreme pH levels.

Applications and Limitations

Electropolishing is widely used in industries where cleanliness and corrosion resistance are paramount, such as:

- Pharmaceutical manufacturing equipment

- Food processing machinery

- Aerospace components

- Medical implants and surgical instruments

However, electropolishing does have some limitations. It may not be suitable for very large components due to bath size constraints, and the process can be more expensive than other surface treatments. Additionally, it may slightly reduce the dimensions of the treated part, which must be accounted for in precision applications.

Chemical Passivation: Enhancing the Natural Oxide Layer

The Science Behind Passivation

Passivation is a chemical process that enhances the formation of a protective oxide layer on the surface of nickel alloy bars. This treatment works by removing free iron and other contaminants from the surface, allowing a more stable and uniform oxide layer to form. The passivation process typically involves immersing the alloy in an acid solution, often nitric or citric acid, for a specified period.

The resulting oxide layer acts as a barrier against corrosive elements, significantly improving the alloy's resistance to various forms of corrosion. This layer is self-healing to some extent, meaning that if damaged, it can reform in the presence of oxygen.

Passivation Techniques for Nickel Alloys

Several passivation techniques are commonly used for nickel alloy bars:

- Nitric acid passivation: A traditional method using concentrated nitric acid

- Citric acid passivation: A more environmentally friendly alternative

- High-temperature oxidation: Creates a thicker oxide layer for extreme environments

- Electrochemical passivation: Combines electrical current with chemical treatment

Each technique has its advantages and is selected based on the specific alloy composition and intended application.

Performance Benefits and Considerations

Passivation offers several key benefits for nickel alloy bars:

- Enhanced resistance to pitting and crevice corrosion

- Improved performance in oxidizing environments

- Increased durability in marine and chemical processing applications

- Cost-effective treatment for large batches of components

However, it's important to note that passivation is not a coating and does not add material to the surface. The effectiveness of passivation can also vary depending on the specific alloy composition and environmental conditions. Regular maintenance and re-passivation may be necessary for optimal long-term performance in highly corrosive environments.

Conclusion

Surface treatments are indispensable for maximizing the corrosion resistance of nickel alloy bars. Electropolishing and passivation stand out as highly effective methods, each offering unique benefits. Electropolishing creates an ultra-smooth surface that significantly reduces corrosion initiation sites, while passivation enhances the natural protective oxide layer. The choice between these treatments depends on specific application requirements, environmental conditions, and economic considerations. For optimal results, it's crucial to work with experienced manufacturers who can recommend and apply the most suitable treatment for your nickel alloy bar needs. By leveraging these advanced surface treatments, industries can ensure their components maintain peak performance and longevity even in the most challenging corrosive environments.

FAQs

How long does a surface treatment last on a nickel alloy bar?

The durability of surface treatments varies depending on the specific treatment and operating conditions. Electropolishing can provide long-lasting protection, often for the lifetime of the component. Passivation may require periodic reapplication, typically every 1-3 years in harsh environments.

Can surface treatments be applied to all types of nickel alloy bars?

Most surface treatments can be applied to a wide range of nickel alloys. However, the effectiveness and process parameters may vary depending on the specific alloy composition. It's essential to consult with a specialist to determine the best treatment for your particular nickel alloy bar.

Experience the TSM Technology Advantage in Nickel Alloy Bar Surface Treatments

At TSM Technology, we specialize in providing top-quality nickel alloy bars with advanced surface treatments for superior corrosion resistance. Our state-of-the-art facility, equipped with 100+ machines across 8 production lines, ensures precision and consistency in every product. We offer customized solutions, including electropolishing and passivation, to meet your specific needs. With our AS9100D certification and rigorous quality control processes, you can trust TSM for nickel alloy bars that exceed industry standards. Contact us at info@tsmnialloy.com to discover how our expertise can enhance your projects.

References

ASTM International. (2021). "Standard Practice for Cleaning, Descaling, and Passivation of Stainless Steel Parts, Equipment, and Systems."

Davis, J.R. (2000). "Nickel, Cobalt, and Their Alloys." ASM International.

Fontana, M.G. (2018). "Corrosion Engineering." McGraw-Hill Education.

Revie, R.W., & Uhlig, H.H. (2008). "Corrosion and Corrosion Control: An Introduction to Corrosion Science and Engineering." Wiley-Interscience.

Stainless Steel World. (2022). "Surface Treatments for Improved Corrosion Resistance in Nickel Alloys."

Tverberg, J.C. (2019). "The Role of Alloying Elements in Nickel Alloy Corrosion Resistance." Materials Performance.

Learn about our latest products and discounts through SMS or email