- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

What Thicknesses Are Available for Monel Sheets?

The thickness of Monel sheets can be anywhere from 0.5 mm to 50 mm, so they can be used in a wide range of commercial settings. Standard thickness ranges include very thin gauges for precise parts and heavy-duty plates for building purposes. The nickel-copper alloy makes sure that the mechanical properties stay the same no matter what thickness is used. Specialized production methods keep the dimensions and surface quality accurate. Knowing the different thickness choices helps engineers and procurement professionals choose the best specifications for each project, whether it's for use in the ocean, in chemical processing, or in space travel.

Overview of Monel Sheets and Their Thickness Significance

Monel is a high-quality nickel-copper alloy that is known for its high resistance to corrosion, high mechanical strength, and long life in harsh industrial settings. Choosing the right thickness is important for more reasons than just meeting basic size standards. It affects how well the material works overall, how well it works with other materials, and how reliable it is over time. For modern industrial uses, exact thickness requirements are needed to make sure that parts work well and don't cost too much over the course of their lives.

Understanding Thickness Impact on Performance

The thickness of a material directly affects how well it holds together and how well it can fight environmental damage. In marine and petrochemical uses, thicker sections are especially useful because they can hold more weight and are better protected against strong chemical attacks. Engineers know that changes in thickness can have an effect on electrical traits, thermal conductivity, and how a material behaves when it is under stress.

Engineering Considerations for Thickness Selection

When defining thickness parameters, procurement professionals have to weigh the need for performance against the limitations of the manufacturing process. Better longevity comes from thicker materials, but they can be harder to shape, weld, and machine. When designing parts for aerospace uses, where weight concerns fight with strength needs, this balance becomes very important.

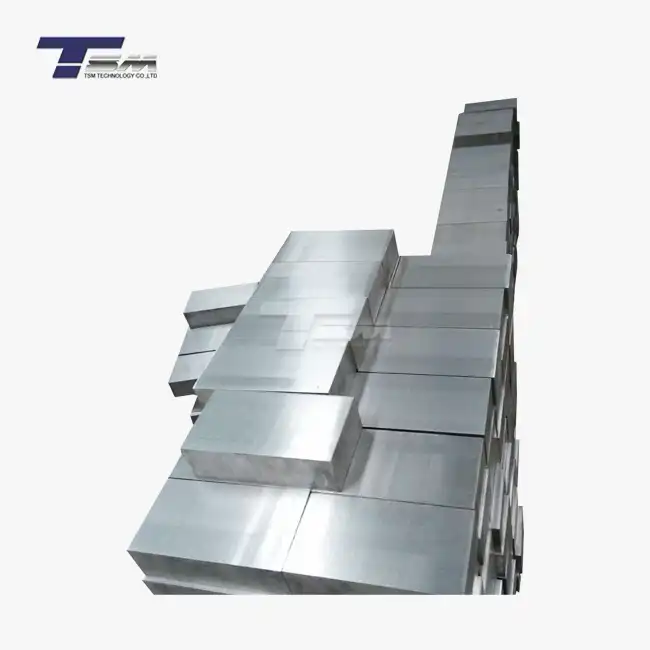

Standard Thickness Ranges Available for Monel Sheets

Industry standards set wide ranges of thicknesses to meet the needs of a wide range of applications in many areas. Monel sheets usually have a width between 0.5 mm for precise uses and 50 mm for heavy-duty structure parts. Standardized ranges like these make sure that they are always available and can be used for both large-scale production and specialized engineering projects.

Ultra-Thin Applications (0.5mm - 2.0mm)

Ultra-thin sections that are easy to shape and have a good surface finish are useful for precision engineering uses. These gauges work great for artistic purposes where corrosion resistance is needed along with good looks, like on electronic parts or the housings of instruments. To keep the dimensions and quality of the surface when making thin sections, you need to use specific rolling methods.

Medium Thickness Range (2.0mm - 10mm)

The category of medium thickness is best for most industrial uses because it strikes the best mix between being easy to work with and being strong. These measurements are often used for marine gear, chemical processing equipment, and heat exchanger parts. The welding quality is great in this range, and the cost of materials and the speed of the work are also good.

Heavy-Duty Applications (10mm - 50mm)

Heavy-gauge materials are used in structural uses that need the most strength and resistance to corrosion. These thicknesses are used to make offshore platforms, pressure vessel parts, and big marine structures that can handle harsh weather. Modern manufacturing methods make sure that the metallurgical qualities of a material are the same across its entire cross-section.

Factors Influencing Thickness Selection in Monel Sheets

For the best project results, thickness selection decisions are based on a number of technical and cost factors. By understanding how these factors affect each other, you can make smart choices about what to buy that balance performance needs with budget limits and manufacturing capabilities.

Corrosion Resistance Considerations

In harsh settings, the thickness of a material has a big effect on how well it resists corrosion. Increasing the thickness adds more material stores to handle uniform corrosion rates while keeping the structure's integrity for longer periods of time. Marine uses benefit most from having thicker sections that are constantly in touch with saltwater.

Mechanical Property Requirements

For load-bearing uses, it's important to carefully look at the thickness to make sure there are enough strength margins for practical stresses. Increasing the thickness of a material makes its tensile strength, yield strength, and fatigue resistance all better. This makes it useful for demanding uses in the energy and aircraft sectors. When setting thickness requirements, design engineers have to think about both static and dynamic loading situations.

Manufacturing and Fabrication Constraints

Choosing the right thickness affects many steps in the manufacturing process, such as cutting, shaping, bonding, and finishing the surface. Some materials are too thick to be processed without special tools or for long periods of time, which can delay projects and increase costs. In contrast, very thin parts need to be handled carefully so that they don't get damaged while they're being made.

Comparative Thickness Insights: Monel Sheets vs Other Alloys

A study of the competition shows that Monel sheet thickness options have clear benefits over other alloy systems. Knowing these differences in benefits helps buying teams choose the right materials based on the needs of the application and the expected performance.

Stainless Steel Comparison

Superior corrosion protection across similar thickness ranges makes Monel better than stainless steel when it comes to strength. Monel doesn't crack easily when exposed to chloride, which is a common problem with stainless steel parts that are used in saltwater. This makes it useful for marine uses.

Inconel and High-Temperature Alloys

Inconel alloys work great in high-temperature situations, but they cost more than Monel-based options. Monel sheets work well in mild temperature ranges and are cheaper for marine and chemical processing uses that don't need to be resistant to very high or very low temperatures.

Titanium Alloy Considerations

Titanium has an incredible strength-to-weight ratio, but it is very hard to work with and costs a lot. In standard thickness ranges, monel has better machinability and welding properties than other metals with similar corrosion protection. This makes it a good choice for parts with complex geometries.

Procurement Guide: How to Buy Monel Sheets by Thickness?

For procurement strategies to work, they need to carefully look at the skills, quality systems, and delivery performance of each provider. Building trusting relationships with suppliers guarantees consistent material quality and supply for a range of thickness needs.

Supplier Qualification Criteria

A thorough evaluation of the supplier's manufacturing skills, compliance with certification requirements, and technical support resources is the first step in quality-focused procurement. Suppliers should show that their whole line of products has the same thickness tolerances, surface finish quality, and chemical makeup control.

Quality Certification Requirements

Material certifications, such as Mill Test Certificates (MTC) and reports from third parties testing the material, are important for making sure the quality of important uses. For aerospace and nuclear uses, detailed records are needed, such as records of heat treatment, test results for mechanical properties, and chemistry analysis data.

Inventory Management Strategies

When planning your inventory, it's important to think about lead times, minimum order amounts, and the thicknesses that are available from different suppliers. Strategic relationships with qualified suppliers make sure that you can always get both standard and custom thickness choices, and they also help you get the most out of your working capital.

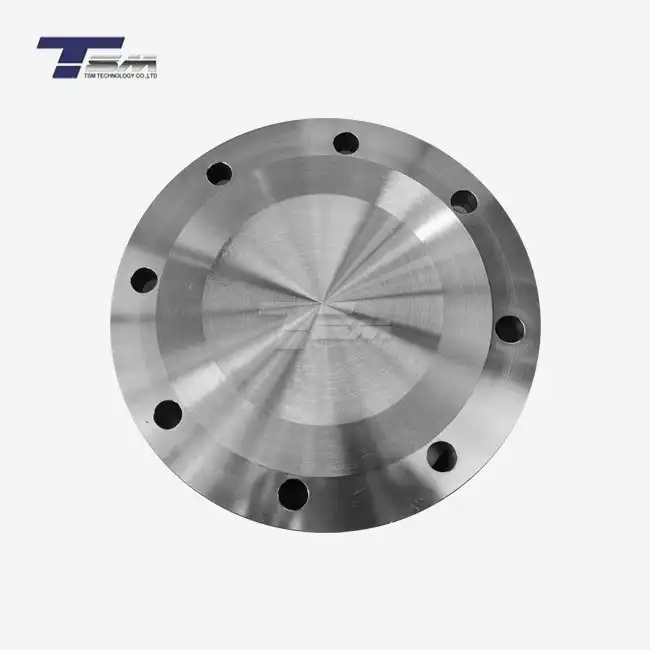

TSM Technology: Your Trusted Monel Sheet Manufacturer

TSM Technology has been providing high-quality nickel alloys to industrial markets around the world for more than 14 years. Our extensive manufacturing skills include three factories with more than 100 machines and eight production lines all devoted to making high-quality Monel sheets in a range of thicknesses, from 0.5 mm to 50 mm.

Advanced Manufacturing Capabilities

Our cutting-edge factories use vacuum induction melting and electroslag remelting methods to make sure that the materials we use are very pure and consistent. Tight tolerances on dimensions are kept by precision rolling techniques, and the mechanical qualities are improved across all thickness ranges by using specific heat treatment methods. Surface finishing techniques, such as grinding and anodizing, make parts ready to use in tough situations.

Quality Assurance Excellence

Full quality control methods make sure that every Monel sheet is delivered in perfect condition. Chemical composition analysis, mechanical property verification, non-destructive examination, and microstructure evaluation are all parts of our testing procedures. Our ISO 9001, AS9100D, and NADCAP certifications show that we are dedicated to quality excellence in the chemical processing, marine, and aerospace businesses.

Customization and Processing Services

We can make a lot of changes, like precision cutting, special surface treatments, and custom dimensional fabrication, in addition to the normal thickness ranges. Our expert team works with customers to find the best solutions for each application's needs while keeping prices low and delivery times on track.

Conclusion

Choosing the right thickness of Monel sheet is a very important choice that affects how well parts work, how efficiently they are made, and how reliable they will be in the long run. The wide range, from 0.5 mm to 50 mm, can be used for a lot of different industrial purposes while still having great mechanical and rust resistance. Understanding how thickness, performance characteristics, and manufacturing constraints affect each other lets you make smart buying decisions that improve the results of your project. TSM Technology's wide range of skills and dedication to quality make it easy to get high-quality Monel sheets in all thicknesses, which helps with project completion in tough industrial settings.

FAQ

1.Where do most Monel sheets fall in terms of thickness?

Monel sheets usually come in thicknesses between 0.5mm and 50mm, so they can be used for everything from very thin precise parts to heavy-duty structural parts. All of the thicknesses in this wide range have the same quality standards and material properties, so they can meet most industry needs.

2.How does the thickness of a Monel sheet affect its ability to prevent corrosion?

Increasing the thickness makes the material more resistant to corrosion by adding more reserves that can handle steady corrosion rates over long work periods. In harsh environments, thicker sections offer better protection. This is especially useful for marine uses that are constantly in contact with saltwater and chemical processing equipment that deals with corrosive media.

3.Can different sizes be made to fit different needs?

The answer is yes, custom thickness manufacturing is possible for specific uses that need exact measurements. Custom orders may have longer wait times and minimum order quantities, but they are the best way to solve engineering problems when standard thicknesses can't meet certain design or performance needs.

4.What should you think about when choosing the thickness of a Monel sheet?

Some important things to think about are the severity of the corrosion environment, the mechanical loading requirements, the fabrication methods, the weight limits, and the cost. While thicker sections are more durable, they can be harder to shape and machine, so it's important to find the right mix between performance needs and manufacturing capabilities.

Contact TSM Technology for Premium Monel Sheet Solutions

When you need to buy Monel sheets, TSM Technology is ready to help with a wide range of thickness choices and high quality standards. Our technical team has a lot of knowledge and can help you find the best material specifications for your needs. You can talk to us about your needs and get free samples by emailing us at info@tsmnialloy.com. As one of the biggest suppliers of Monel sheets, we offer dependable solutions that are backed by strict quality control and the ability to make changes as needed.

References

ASTM International. "Standard Specification for Nickel-Copper Alloy Sheet and Strip." ASTM B127-19, 2019.

Davis, J.R., editor. "ASM Specialty Handbook: Nickel, Cobalt, and Their Alloys." ASM International, 2000.

Rebak, Raul B. "Corrosion of Monel Alloys in Marine Environments: A Comprehensive Review." Materials Performance, Vol. 58, No. 3, 2019.

Smith, William F. and Javad Hashemi. "Foundations of Materials Science and Engineering, Sixth Edition." McGraw-Hill Education, 2019.

International Nickel Company. "Monel Alloy 400: Properties and Applications in Industrial Environments." Technical Bulletin NiDI-001, 2020.

Anderson, Timothy L. "Manufacturing Processes for Nickel-Copper Alloy Sheets: Thickness Control and Quality Assurance." Journal of Materials Processing Technology, Vol. 285, 2020.

Learn about our latest products and discounts through SMS or email