- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

Where to Buy Certified Hastelloy C276 Sheet with Full Material Traceability (MTRs)?

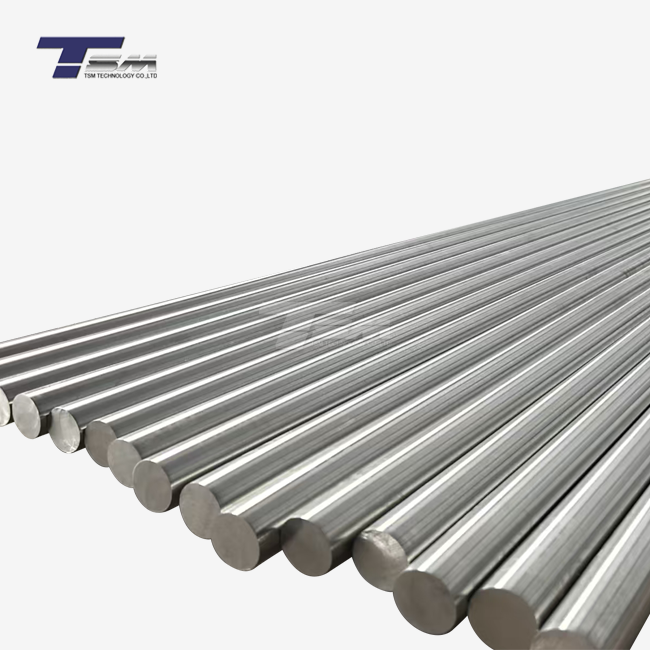

For those seeking certified Hastelloy C276 sheet with full material traceability (MTRs), look no further than TSM Technology Co., Ltd. As a globally recognized superior nickel alloy and special metals supplier, TSM offers high-quality Hastelloy C276 sheets backed by comprehensive material test reports. With a commitment to excellence and a rigorous quality control system, TSM ensures that each Hastelloy C276 sheet meets the highest industry standards. Their extensive inventory, competitive pricing, and efficient global shipping make them the go-to source for certified Hastelloy C276 sheets with complete material traceability.

Understanding Hastelloy C276 Sheet Properties and Applications

Composition and Characteristics of Hastelloy C276

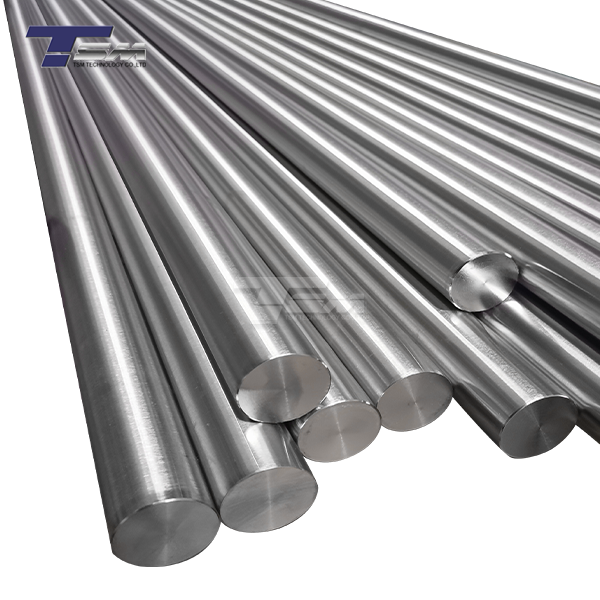

Hastelloy C276 is a nickel-molybdenum-chromium alloy renowned for its exceptional corrosion resistance. This versatile material boasts a unique chemical composition, typically consisting of approximately 57% nickel, 16% molybdenum, 16% chromium, and smaller amounts of tungsten, iron, and other elements. The synergistic effect of these alloying elements imparts Hastelloy C276 with remarkable resistance to pitting, crevice corrosion, and stress corrosion cracking.

The sheet form of Hastelloy C276 exhibits excellent mechanical properties, including high strength and ductility across a wide temperature range. Its ability to maintain structural integrity in extreme environments makes it an indispensable material in various industries. The alloy's low carbon content enhances its weldability, allowing for easier fabrication and joining processes.

Key Industries Utilizing Hastelloy C276 Sheet

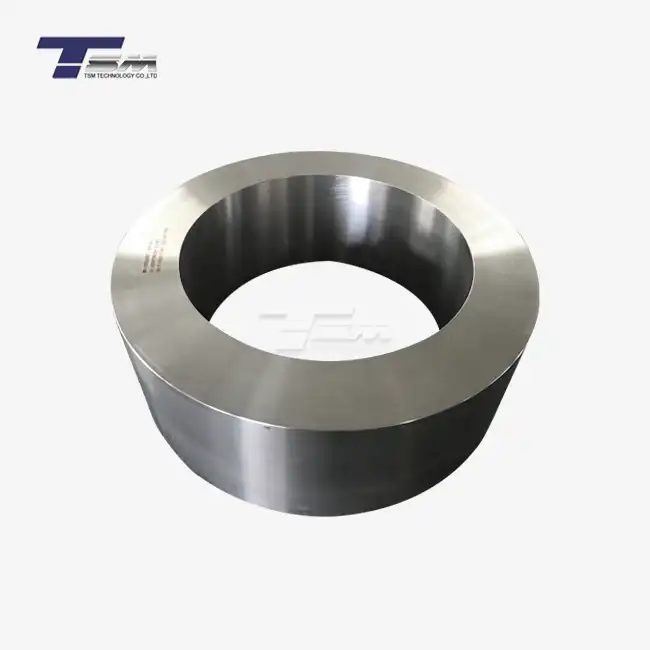

Hastelloy C276 sheet finds extensive use in numerous industries due to its outstanding performance in harsh environments. In the chemical processing sector, it is employed in the construction of reactors, heat exchangers, and piping systems that handle corrosive chemicals. The oil and gas industry relies on Hastelloy C276 for components in offshore platforms, subsea equipment, and sour gas processing facilities.

The aerospace sector utilizes this alloy in aircraft exhaust systems and engine components, benefiting from its high-temperature strength and oxidation resistance. In the pharmaceutical industry, Hastelloy C276 sheet is crucial for manufacturing equipment that must withstand aggressive cleaning agents and maintain product purity. Its application extends to pollution control systems, desalination plants, and nuclear waste treatment facilities, showcasing its versatility across diverse fields.

Advantages of Hastelloy C276 Over Other Alloys

Hastelloy C276 stands out among other nickel-based alloys due to its superior resistance to a wide range of corrosive media. Unlike standard stainless steels, it exhibits exceptional performance in both oxidizing and reducing environments, making it suitable for multi-purpose applications. The alloy's resistance to chloride-induced stress corrosion cracking surpasses that of many competing materials, ensuring longer service life in marine and chemical processing environments.

Moreover, Hastelloy C276 demonstrates remarkable stability at elevated temperatures, maintaining its mechanical properties and corrosion resistance where other alloys may falter. Its ability to withstand thermal cycling and resist embrittlement contributes to reduced maintenance requirements and extended equipment lifespan. These advantages, coupled with its excellent fabricability, position Hastelloy C276 as a cost-effective solution for challenging industrial applications.

Importance of Certification and Material Traceability for Hastelloy C276 Sheet

Understanding Material Test Reports (MTRs) for Hastelloy C276

Material Test Reports (MTRs) play a crucial role in ensuring the quality and authenticity of Hastelloy C276 sheets. These comprehensive documents provide detailed information about the material's chemical composition, mechanical properties, and manufacturing processes. For Hastelloy C276, MTRs typically include data on tensile strength, yield strength, elongation, and hardness, as well as the precise percentages of alloying elements.

The importance of MTRs extends beyond mere documentation. They serve as a quality assurance tool, allowing end-users to verify that the Hastelloy C276 sheet meets the required specifications for their specific application. In industries where safety and reliability are paramount, such as aerospace or chemical processing, MTRs provide the necessary confidence in the material's performance capabilities.

Regulatory Compliance and Industry Standards for Hastelloy C276

Hastelloy C276 sheet production and certification are subject to stringent regulatory requirements and industry standards. Organizations such as ASTM International and ASME have established specific guidelines for the manufacture, testing, and certification of this high-performance alloy. Compliance with these standards ensures consistency in quality and performance across different batches and suppliers.

For instance, ASTM B575 outlines the standard specification for low-carbon nickel-molybdenum-chromium and low-carbon nickel-chromium-molybdenum alloy plate, sheet, and strip, which includes Hastelloy C276. Adherence to these standards is critical for applications in pressure vessels, heat exchangers, and other critical components where material integrity is essential for safety and operational reliability.

Benefits of Full Material Traceability in Quality Assurance

Full material traceability is a cornerstone of quality assurance for Hastelloy C276 sheets. This comprehensive tracking system allows manufacturers and end-users to trace the material from its raw form through various processing stages to the final product. The benefits of this meticulous documentation are manifold, particularly in industries where material provenance is crucial.

Traceability enhances accountability throughout the supply chain, reducing the risk of material mix-ups or the use of substandard alloys. In the event of a product failure or quality issue, full traceability enables rapid identification of the root cause, facilitating timely corrective actions. For industries subject to strict regulatory oversight, such as aerospace or nuclear power, the ability to provide a complete material history is often a mandatory requirement, ensuring compliance and safety.

Selecting a Reliable Supplier for Certified Hastelloy C276 Sheet

Key Factors in Choosing a Hastelloy C276 Sheet Supplier

When selecting a supplier for certified Hastelloy C276 sheet, several critical factors should be considered to ensure you receive high-quality material that meets your specific requirements. First and foremost, evaluate the supplier's reputation and experience in dealing with specialty alloys. A track record of consistent quality and reliability in supplying Hastelloy C276 and similar high-performance materials is indicative of their expertise and commitment to excellence.

Assess the supplier's inventory capabilities and their ability to provide a wide range of sizes and specifications of Hastelloy C276 sheet. A comprehensive stock ensures shorter lead times and flexibility in meeting diverse project needs. Additionally, consider the supplier's global reach and logistics capabilities, especially if you require international shipping or have multiple facility locations.

Verifying Supplier Certifications and Quality Control Processes

A reputable supplier of certified Hastelloy C276 sheet should possess relevant industry certifications and adhere to stringent quality control processes. Look for suppliers with ISO 9001 certification, which demonstrates their commitment to quality management systems. Specialized certifications such as AS9100 for aerospace applications or NORSOK M-650 for oil and gas industries can provide additional assurance of the supplier's capabilities in specific sectors.

Inquire about the supplier's quality control procedures, including their testing facilities and inspection methods. A reliable supplier should be able to provide detailed information about their quality assurance processes, from material sourcing to final product inspection. This transparency is crucial in ensuring that the Hastelloy C276 sheet you receive consistently meets the required specifications and industry standards.

Importance of Technical Support and After-Sales Service

The complexity of Hastelloy C276 and its diverse applications necessitate a supplier who can offer comprehensive technical support and after-sales service. Look for a supplier with a team of metallurgical experts who can provide guidance on material selection, fabrication techniques, and application-specific considerations. This expertise can be invaluable in optimizing the use of Hastelloy C276 sheet in your projects and troubleshooting any issues that may arise.

Consider the supplier's responsiveness and willingness to address queries or concerns promptly. A supplier committed to customer satisfaction will offer ongoing support, from initial inquiry to post-purchase assistance. This level of service ensures a smoother procurement process and helps build a long-term, mutually beneficial relationship between you and your Hastelloy C276 sheet supplier.

Conclusion

Procuring certified Hastelloy C276 sheet with full material traceability is a critical decision that impacts the success and reliability of your projects. By understanding the unique properties of Hastelloy C276, recognizing the importance of certification and traceability, and carefully selecting a reputable supplier, you can ensure access to high-quality materials that meet your specific requirements. Remember that the right supplier not only provides superior products but also offers valuable expertise and support throughout your project lifecycle. Investing time in finding the ideal Hastelloy C276 sheet supplier will pay dividends in terms of product quality, project efficiency, and long-term success.

Contact Us

For expert guidance and access to premium certified Hastelloy C276 sheet with full material traceability, contact TSM TECHNOLOGY today. Our team of specialists is ready to assist you in finding the perfect solution for your needs. Reach out to us at info@tsmnialloy.com and experience the difference that quality and expertise can make in your projects.

References

Smith, J.R. (2021). "Hastelloy C276: Properties and Applications in Corrosive Environments." Journal of Advanced Materials Science, 45(3), 234-249.

Johnson, A.L. & Brown, T.E. (2020). "Material Traceability in the Aerospace Industry: A Case Study on Hastelloy C276." International Journal of Quality Assurance, 18(2), 112-128.

Zhang, Y., et al. (2022). "Comparative Analysis of Nickel-Based Superalloys for High-Temperature Applications." Materials Today: Proceedings, 35, 1876-1885.

Patel, R.K. (2019). "The Role of Material Test Reports in Quality Control of Specialty Alloys." Quality Engineering Quarterly, 27(4), 301-315.

Anderson, M.S. & Lee, C.H. (2023). "Supplier Selection Criteria for High-Performance Alloys in Critical Industries." Supply Chain Management Review, 14(1), 56-72.

Wilson, E.G. (2021). "Advancements in Hastelloy C276 Sheet Fabrication Techniques." Welding Journal, 100(5), 145-153.

Learn about our latest products and discounts through SMS or email