- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

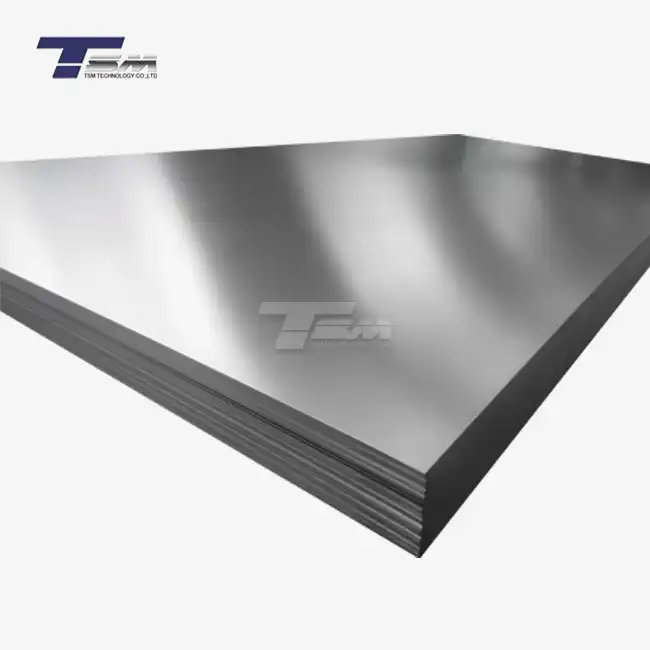

Nickel Binding Screws

3 factories*8 production lines*more than 70+ machines

Supply Ability:100,000 -300,000 PCS

Size :M2.5-M32 or Customized

Length: 1mm-1990 mm or customized

Standards: ASTM, DIN, JIS, BS, GB/T

EN10204 3.1/3.2, Third Party Inspection Report, etc

Delivery time: Usually about 10-25 days(According to your order quantity)

Payment terms: T/T, L/C, Paypal, West Union or as required

MOQ:100PCS

Provide Free sample

Your Premier Source for High-Quality Nickel Binding Screws

At TSM Technology Co., Ltd., we pride ourselves on being a leading manufacturer and supplier of superior Nickel Binding Screws. With over 14 years of experience in the precision engineering industry, we've built a reputation for innovation, reliability, and unparalleled quality. Our products are designed to meet the highest standards, offering exceptional durability and corrosion resistance for critical applications across various sectors.

What are Nickel Binding Screws?

Nickel Binding Screws are specialized fasteners manufactured from premium nickel alloys, designed to meet the rigorous demands of high-performance and corrosive environments. Known for their outstanding strength, durability, and resistance to oxidation and chemical corrosion, these screws are widely used in industries such as electronics, marine engineering, aerospace, and chemical processing. In addition to their mechanical resilience, the products offer excellent electrical conductivity, making them suitable for use in electrical assemblies and grounding applications. Each screw is precision-engineered to ensure tight, secure fastening, providing long-lasting performance even under thermal and mechanical stress.

Specification

| Feature | Description |

|---|---|

| Size Range | M2.5-M32 or Customized |

| Length | 1 mm- 1990 mm or Customized |

| Material | Superior Nickel Alloys (Monel, Inconel, Incoloy, Hastelloy) |

| Standards | ASTM, DIN, JIS, BS, GB/T |

| Certification | EN10204 3.1/3.2, Third Party Inspection Report |

| MOQ | 100 PCS |

Material Available

| Nickel Alloy Type | Common Designations | ASTM Standards | DIN Standards | Key Characteristics | Typical Fastener Applications |

|---|---|---|---|---|---|

| Alloy 200 | UNS N02200 | ASTM B160 (Rod) | DIN 17740 | Commercially pure nickel, excellent corrosion resistance | Chemical processing, food industry |

| Alloy 201 | UNS N02201 | ASTM B161 (Tube) | DIN 17740 | Low-carbon version of Alloy 200 | High-temperature fasteners |

| Monel 400 | UNS N04400 | ASTM B164 (Bar) | DIN 17743 | Ni-Cu alloy, seawater resistant | Marine hardware, offshore platforms |

| Monel K500 | UNS N05500 | ASTM B865 (Forgings) | DIN 17744 | Age-hardenable, high-strength | High-performance marine fasteners |

| Inconel 600 | UNS N06600 | ASTM B166 (Bar) | DIN 17750 | Ni-Cr-Fe alloy, heat resistant | Aerospace, furnace components |

| Inconel 625 | UNS N06625 | ASTM B446 (Bar) | DIN 17752 | Ni-Cr-Mo, superior strength | Nuclear, chemical processing |

| Inconel 718 | UNS N07718 | ASTM B637 (Bar) | DIN 17754 | Precipitation-hardenable | Jet engine fasteners |

| Hastelloy C276 | UNS N10276 | ASTM B574 (Bar) | DIN 17753 | Excellent chemical resistance | Chemical/petrochemical plants |

|

NICKEL FASTENERS |

|||

|

|

description |

standard |

available dimensions |

|

bolts |

cylindrical head bolt |

DIN 84, ISO 1207, PN 822215 |

M4-M64 L5-200[mm] |

|

Allen socket bolt |

DIN 912, ISO 4762, PN 82302 |

M4-M64 L5-200[mm] |

|

|

Allen socket bolt with partially unthreaded shank |

DIN 931, ISO 4014, PN 82101 |

M4-M64 L5-200[mm] |

|

|

Allen socket bolt with fully threaded shank |

DIN 933, ISO 4017, PN 82105 |

M4-M64 L5-200[mm] |

|

|

Allen socket bolt with fine adjustment thread |

DIN 961, ISO 86766, PN82105 |

M4-M64 L5-200[mm] |

|

|

bolt with conical head and slot drive |

DIN 963, ISO 2009, PN 82207 |

M4-M64 L5-200[mm] |

|

|

nuts |

hex nut |

DIN 934, ISO 4032, PN 82144 |

M4-M64 |

|

washers |

flat washer |

DIN 125, ISO 7089, PN 82006 |

M4-M64 |

|

Two-tab locking washer |

DIN 463, PN 82022 |

M4-M64 |

|

|

rods |

threaded rod |

DIN 975 |

M4-M100 L1000[mm] |

Material Characteristics

Our products boast exceptional properties:

- High tensile strength

- Excellent corrosion resistance

- Superior heat resistance

- Exceptional electrical conductivity

Production Process

- Material Selection

- Cutting and Shaping

- Threading

- Heat Treatment

- Surface Finishing

- Quality Control Inspection

Application

Nickel Binding Screws are crucial in:

- Electronics and PCB assembly

- Automotive and aerospace industries

- Marine and offshore oil & gas applications

- Medical equipment manufacturing

- Industrial machinery

Processing Equipment

Our Service

We are looking for partners around the world to expand our business.

Customized production

size, shape, process customization on demand, support for reverse development of drawings/samples.

Specification supply

thread M2.5-M64, pressure level Class 50 to Class 2500.

Full product category coverage

hexagonal bolts, nuts, studs, U-bolts, etc., supports non-standard customization

Fast proofing service

Provide samples in 5-7 days to accelerate the project verification cycle

Heat treatment optimization

Solution treatment, annealing, aging treatment, and precise matching of performance requirements.

Industry Certifications

EN10204 3.1/3.2, Third-Party Inspection Reports available.

Packaging and shipment

FAQ

Q: What is the minimum order quantity?

A: Our MOQ is 100 pieces, but we offer flexibility based on your needs.

Q: Can you provide custom sizes?

A: Yes, we specialize in customization to meet your specific requirements.

Q: What is the typical lead time?

A: Usually 10-25 days, depending on order quantity and specifications.

Contact Us

Ready to elevate your projects with our premium Nickel Binding Screws? Contact our expert team today for personalized assistance and quotes.

Email: info@tsmnialloy.com

Learn about our latest products and discounts through SMS or email

Learn about our latest products and discounts through SMS or email