- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

Nickel Nuts

3 factories*8 production lines*more than 70+ machines

Supply Ability:100,000 -300,000 PCS

Size :M2.5-M32 or Customized

Length: 1mm-1990 mm or customized

Standards: ASTM, DIN, JIS, BS, GB/T

EN10204 3.1/3.2, Third Party Inspection Report, etc

Delivery time: Usually about 10-25 days(According to your order quantity)

Payment terms: T/T, L/C, Paypal, West Union or as required

MOQ:100PCSProvide Free sample

Nickel Nuts Manufacturer And Supplier

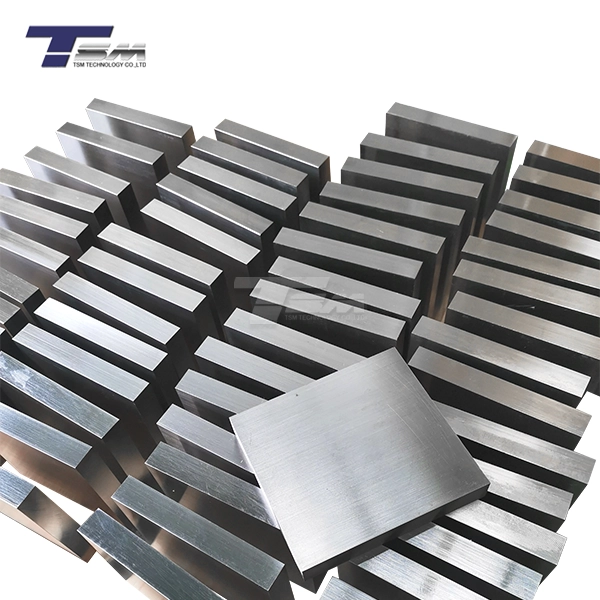

TSM Technology specializes in manufacturing high-performance nickel nuts from premium-grade specialty alloys to meet the most demanding industrial requirements. Our nuts are engineered from premium-grade materials like Hastelloy®, Inconel®, and Monel®, offering unmatched corrosion resistance, strength, and durability for chemical processing, marine, aerospace, and energy applications. Engineered to perform under extreme temperatures, pressures, and chemical exposure, they ensure long-term reliability and safety. With over 14 years of precision engineering experience, TSM Technology upholds strict quality control and utilizes advanced manufacturing equipment to deliver consistent, high-performance products. Our products meet international standards, making them the trusted choice for demanding applications requiring superior corrosion resistance and mechanical integrity.

What are Nickel Nuts?

The products are high-performance fasteners made from pure nickel or nickel-based alloys, specifically engineered for use in harsh environments. Unlike standard carbon or stainless steel nuts, they offer exceptional resistance to heat, corrosion, and aggressive chemicals. Commonly used alloys include Inconel, Monel, and Hastelloy, each selected based on the application’s demands. These nuts are vital in industries such as aerospace, marine, oil and gas, and chemical processing. Beyond corrosion resistance, they provide excellent mechanical strength, thermal stability, and long service life under stress or fluctuating temperatures. Their durability reduces maintenance needs and enhances safety and performance in critical applications, making them a reliable, cost-effective solution for demanding industrial settings.

Supply Type

| Type |

Hex Nut |

Flanged / Collared Hex Nuts |

Acorn Nuts |

Locking Nuts |

Slotted Nuts |

|

Round Nuts |

T-Nuts |

Tinnerman-Style Nuts |

Snap-In Nuts |

Wheel Nuts |

|

|

Available Size: |

M1-M64 |

||||

Product Standards and Available Materials Selection

TSM Technology's products comply with international standards, including:

| Nickel Alloy Type | Common Designations | ASTM Standards | DIN Standards | Key Characteristics | Typical Fastener Applications |

|---|---|---|---|---|---|

| Alloy 200 | UNS N02200 | ASTM B160 (Rod) | DIN 17740 | Commercially pure nickel, excellent corrosion resistance | Chemical processing, food industry |

| Alloy 201 | UNS N02201 | ASTM B161 (Tube) | DIN 17740 | Low-carbon version of Alloy 200 | High-temperature fasteners |

| Monel 400 | UNS N04400 | ASTM B164 (Bar) | DIN 17743 | Ni-Cu alloy, seawater resistant | Marine hardware, offshore platforms |

| Monel K500 | UNS N05500 | ASTM B865 (Forgings) | DIN 17744 | Age-hardenable, high-strength | High-performance marine fasteners |

| Inconel 600 | UNS N06600 | ASTM B166 (Bar) | DIN 17750 | Ni-Cr-Fe alloy, heat resistant | Aerospace, furnace components |

| Inconel 625 | UNS N06625 | ASTM B446 (Bar) | DIN 17752 | Ni-Cr-Mo, superior strength | Nuclear, chemical processing |

| Inconel 718 | UNS N07718 | ASTM B637 (Bar) | DIN 17754 | Precipitation-hardenable | Jet engine fasteners |

| Hastelloy C276 | UNS N10276 | ASTM B574 (Bar) | DIN 17753 | Excellent chemical resistance | Chemical/petrochemical plants |

Size Range:M2.5 - M32 or custom

Length:1mm - 1990mm or custom

Material:Nickel alloys (e.g., Monel, Inconel, Incoloy)

Standards:ASTM, DIN, JIS, BS, GB/T

Certifications:EN10204 3.1/3.2, Third Party Inspection

Our products boast:

- Superior corrosion resistance

- High-temperature strength

- Excellent mechanical properties

- Non-magnetic properties (select alloys)

- Resistance to stress-corrosion cracking

Our Nickel Nuts find use in:

- Offshore oil & gas platforms

- Chemical processing equipment

- Nuclear power plants

- Aerospace engine components

- Marine propulsion systems

- High-temperature industrial furnaces

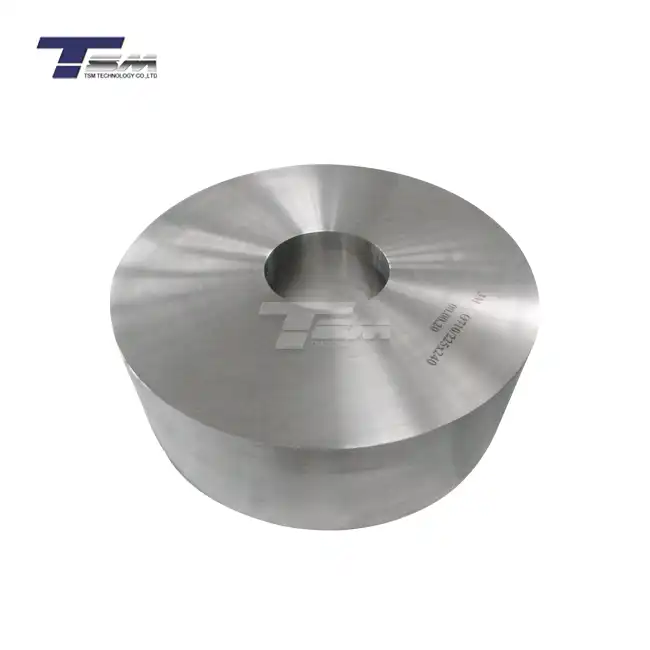

Advanced Manufacturing Processes

CNC Turning & Milling: Precision threading and head machining for tight tolerances (±0.005 mm).

Thread Rolling: Cold-forming technology enhances thread strength and fatigue resistance.

Stress Relief Annealing: Ensures dimensional stability under load.

100% Inspection: Each nut is verified with GO/NO-GO gauges and ultrasonic testing (UT).

Custom Solutions

Sizes: M4 to M100 (metric) / #2 to 4" (imperial).

Standards: DIN, ANSI, ISO, ASME, or customer-specific designs.

Coatings: Optional PTFE, Xylan, or electroless nickel plating for enhanced performance.

Processing Equipment

Why Choose Us?

Quality Assurance

EN10204 3.1/3.2 certification and third-party inspection

Custom-made

Sizes ranging from M2.5-M32, or as per your requirements.

Fast Delivery

Reliable shipping within 10-25 days worldwide.

Competitive Pricing

Best industry rates for bulk orders.

Packaging and shipment

Certifications

ISO 9001:2015 Quality Management System

API Q1 (American Petroleum Institute)

NORSOK M-650 (for oil & gas applications)

PED 2014/68/EU (Pressure Equipment Directive)

FAQ

Q: What is the minimum order quantity (MOQ)?

A: Our standard MOQ is 100 pieces, but we offer free samples for evaluation.

Q: Can you provide custom sizes or materials?

A: Yes, we specialize in customization to meet your specific requirements.

Q: What is the typical lead time for orders?

A: Generally, 10-25 days, depending on order quantity and specifications.

Contact Us

Ready to enhance your projects with our superior Nickel Nuts? Contact our expert team today for quotes, technical support, or custom inquiries.

Email:info@tsmnialloy.com

Learn about our latest products and discounts through SMS or email

Learn about our latest products and discounts through SMS or email