Nickel Studs are high-performance fasteners manufactured from pure nickel or advanced nickel-based alloys, specifically engineered for use in demanding industrial environments. These studs are known for their exceptional resistance to corrosion, oxidation, and high temperatures, making them ideal for critical applications where standard materials would fail. They are widely used in industries such as oil and gas, chemical processing, marine engineering, and power generation, where reliability and strength are non-negotiable. Our products provide long-term durability and stable performance, even when exposed to aggressive chemicals, saltwater, or extreme thermal conditions, ensuring safety and reduced maintenance needs.

- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

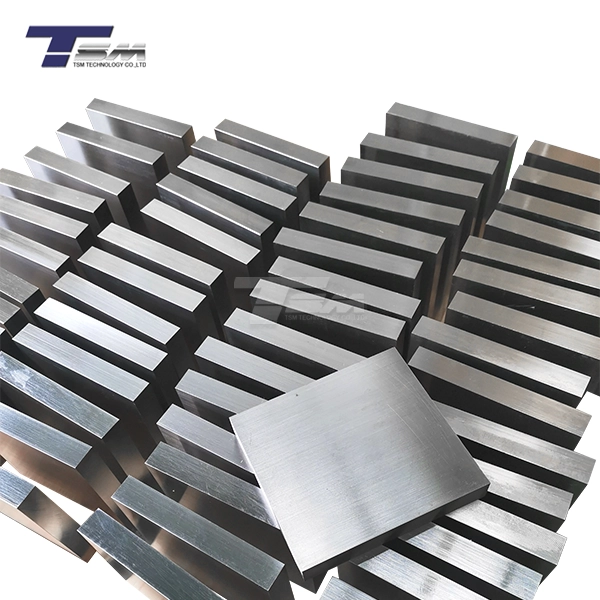

Nickel Studs

3 factories*8 production lines*more than 70+ machines

Supply Ability:100,000 -300,000 PCS

Size :M2.5-M32 or Customized

Length: 1mm-1990 mm or customized

Standards: ASTM, DIN, JIS, BS, GB/T

EN10204 3.1/3.2, Third Party Inspection Report, etc

Delivery time: Usually about 10-25 days(According to your order quantity)

Payment terms: T/T, L/C, Paypal, West Union or as required

MOQ:100PCSProvide Free sample

Your Premier Source for High-Quality Nickel Studs

TSM Technology specializes in manufacturing a variety of special alloy nickel studs, using high-quality materials such as Hastelloy, Inconel and Monel to provide high-performance fastening solutions for demanding applications such as chemical, aerospace and offshore engineering. We can provide precisely customized corrosion-resistant, high-temperature resistant and high-strength stud products based on your specific needs. With over 14 years of experience in the industry, we've honed our expertise to deliver products that consistently exceed customer expectations.

What are Nickel Studs?

Supply Type

| Product Name | Product Description | Key Advantages |

|---|---|---|

| Full Thread Studs | TSM Technology manufactures full thread studs using specialty alloys including Hastelloy®, Inconel®, Monel® and titanium. The full-length thread design ensures even load distribution, ideal for demanding applications like oil pipelines, pressure vessels and power equipment. | Optimized tensile strength Corrosion/heat-resistant materials Custom lengths (up to 12m) |

| Double End Studs | Precision-engineered with dual-end threading for flange connections and high-pressure sealing. Available in corrosion-resistant nickel alloys and high-strength titanium, widely used in chemical reactors, nuclear valves and offshore platforms. | Custom threading on both ends Surface treatments available ASME B16.5 compliant |

| Threaded Rod | Standard and custom threaded rods for construction, power transmission and other harsh environments. Optional UV-resistant coating or electropolishing for long-term stability in corrosive conditions. | 6g/6H tolerance class Cold/hot rolled options Precision cutting service (±0.5mm) |

Specification

| Parameter | Details |

|---|---|

| Size Range | M2.5 - M32 (Customizable) |

| Length | 1mm - 1990mm (Customizable) |

| Standards | ASTM, DIN, JIS, BS, GB/T |

| Material | High-grade Nickel Alloys |

| Supply Capacity | 100,000 - 300,000 PCS |

Product Standards

Our Nickel studs comply with international standards, including:

| Nickel Alloy Type | Common Designations | ASTM Standards | DIN Standards | Key Characteristics | Typical Fastener Applications |

|---|---|---|---|---|---|

| Alloy 200 | UNS N02200 | ASTM B160 (Rod) | DIN 17740 | Commercially pure nickel, excellent corrosion resistance | Chemical processing, food industry |

| Alloy 201 | UNS N02201 | ASTM B161 (Tube) | DIN 17740 | Low-carbon version of Alloy 200 | High-temperature fasteners |

| Monel 400 | UNS N04400 | ASTM B164 (Bar) | DIN 17743 | Ni-Cu alloy, seawater resistant | Marine hardware, offshore platforms |

| Monel K500 | UNS N05500 | ASTM B865 (Forgings) | DIN 17744 | Age-hardenable, high-strength | High-performance marine fasteners |

| Inconel 600 | UNS N06600 | ASTM B166 (Bar) | DIN 17750 | Ni-Cr-Fe alloy, heat resistant | Aerospace, furnace components |

| Inconel 625 | UNS N06625 | ASTM B446 (Bar) | DIN 17752 | Ni-Cr-Mo, superior strength | Nuclear, chemical processing |

| Inconel 718 | UNS N07718 | ASTM B637 (Bar) | DIN 17754 | Precipitation-hardenable | Jet engine fasteners |

| Hastelloy C276 | UNS N10276 | ASTM B574 (Bar) | DIN 17753 | Excellent chemical resistance | Chemical/petrochemical plants |

Product Details

Material Characteristics

- Excellent corrosion resistance

- High-temperature strength

- Superior mechanical properties

- Exceptional durability in harsh environments

Applications

- Petrochemical industry equipment

- Offshore oil and gas platforms

- Chemical processing plants

- Marine and naval engineering

- Aerospace components

- Power generation facilities

Processing Equipment

Our Service

We are looking for partners around the world to expand our business.

Customized drawings and model production

Customized 3D drawings and CAD models are produced according to customer needs to help customers better understand and confirm product designs.

Dimensions and tolerances

Comply with ISO 4759-1 standards, thread accuracy reaches 6g/6H level, diameter range M1~M30, suitable for minimally invasive medical devices to large mechanical assembly.

Reliable global supply

With global distribution capabilities, we can provide reliable logistics solutions no matter where customers are

Quality control

From raw material procurement to finished product inspection, every link is strictly controlled to ensure stable and reliable product quality.

After-sales service

We have established a dedicated after-sales team to respond to customer needs in a timely manner. If there are product quality problems or customer dissatisfaction, we provide a flexible return and exchange policy.

Sample trial production service

Provide free samples or small batch trial production services to help you verify product performance and reduce trial and error costs.

TSM Technology is a superior nickel alloy and special metals supplier and stockist. We are dedicated to providing quality superior alloys such as Nickel、Monel、Inconel、Incoloy、Hastelloy、High Temperature alloy to the precision engineering industry and machine shops globally, such as in pharmaceutical, pharmachemical, marine, shore (oil and gas), and medical industries.

Our international trading journey began in 2011 in Hong Kong, Over the 14 years, TSM has continuously evolved and grown, building a reputation for innovation, reliability, and quality in the superior Nickel alloy area.

Packaging and shipment

FAQ

Q: What is the minimum order quantity for products?

A: Our MOQ is 100 PCS, with free samples available upon request.

Q: How long is the typical delivery time?

A: Delivery usually takes 10-25 days, depending on order quantity and specifications.

Q: Can you provide custom sizes?

A: Yes, we offer customization services to meet your exact requirements.

Contact Us

Ready to upgrade your fastening solutions with our premium Nickel studs? Contact our expert team today!

Email: info@tsmnialloy.com

Learn about our latest products and discounts through SMS or email

Learn about our latest products and discounts through SMS or email