- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

Nickel Alloy BL Flange

3 factories*8 production lines*more than 70+ machines

Supply Ability: 300 Tons/month

Grade: MONEL 400, INCONEL 600, HASTELLOY C276

Specifications:ASTM B564 / ASME SB564 / ASME B16.5

Size:1/2″ (15 NB) to 48″ (1200 NB)

Finish: Machine faced with drilled bolt holes

Delivery time: Usually about 10-25 days(According to your order quantity)

Payment way: T/T, L/C, can be negotiated.

Nickel Alloy BL Flange Manufacturer & Supplier

At TSM Technology, we specialize in manufacturing and supplying Nickel Alloy BL Flange with strict quality control and full traceability. We deliver high-performance flanges designed to meet the demanding requirements of the aerospace, medical, petrochemical, and semiconductor industries. Each Nickel Alloy BL Flange is produced with precision and tested to global standards, ensuring top-notch performance, corrosion resistance, and durability.

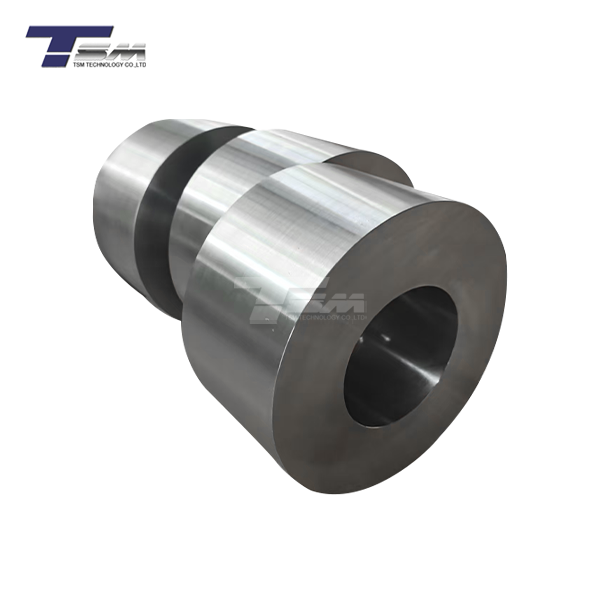

What is Nickel Alloy BL Flange?

Nickel Alloy Blind Flanges (BL) are solid discs used to close off piping systems or nozzles. These flanges offer excellent resistance to corrosion, pressure, and extreme temperatures, making them ideal for critical service applications.

Specification

| Type | Nickel Alloy Blind Flange (BL) |

|---|---|

|

Grades |

Inconel 625, Inconel 718, Hastelloy C22, Monel 400, Nickel 201 |

|

Sizes |

1/2” – 24” (custom sizes available) |

|

Standards |

ASME B16.5 / B16.47, ANSI, EN1092, DIN |

|

Pressure Ratings |

Class 150 – 2500 |

|

Surface Finish |

Machined / Pickled / Sandblasted / Polished |

|

Connection |

Raised Face (RF), Flat Face (FF), RTJ |

|

Customization |

Drilled or solid, special dimensions, surface treatment |

Physical & Chemical Properties

| Property | Nickel 201 (UNS N02201) | Monel K500 (UNS N05500) | Inconel 718 (UNS N07718) | Hastelloy C276 (UNS N10276) |

|---|---|---|---|---|

| Physical Properties | ||||

| Density (g/cm³) | 8.89 | 8.44 | 8.19 | 8.89 |

| Melting Point (°C) | 1440-1455 | 1315-1350 | 1260-1340 | 1325-1370 |

| Thermal Conductivity (W/m·K) | 61.8 | 22.1 | 11.4 | 10.2 |

| Electrical Resistivity (μΩ·m) | 0.48 | 0.54 | 1.25 | 1.30 |

| Mechanical Properties | ||||

| Tensile Strength (MPa) | 380-480 | 760-1030 | 1240-1380 | 690-790 |

| Yield Strength (MPa) | 120-170 | 550-690 | 1030-1170 | 310-410 |

| Hardness (HRB/HRC) | HRB 40-75 | HRB 65-100 | HRC 35-45 | HRB 85-100 |

| Chemical Composition (%) | ||||

| Nickel (Ni) | ≥99.0 | 63-67 | 50-55 | Balance |

| Chromium (Cr) | - | - | 17-21 | 14.5-16.5 |

| Molybdenum (Mo) | - | - | 2.8-3.3 | 15.0-17.0 |

| Copper (Cu) | ≤0.4 | 27-33 | - | - |

| Iron (Fe) | ≤0.4 | ≤2.0 | Balance | 4.0-7.0 |

| Corrosion Resistance | ||||

| Acid Resistance | Excellent (HF, NaOH) | Good (H₂SO₄, seawater) | Moderate (HCl, H₂S) | Outstanding (HCl, HNO₃ mix) |

| Pitting/Crevice Resistance | Good | Excellent | Good | Exceptional |

| Max Service Temp (°C) | 600 | 480 | 700 | 400 ( |

Product Standards

Our Nickel Alloy BL Flanges conform to the following standards:

ASTM B564 / B366 / B462, ASME B16.5 / B16.47, NACE MR0175 for sulfide stress cracking resistance, ISO 13485 (for medical biocompatibility), NADCAP-certified processes (for aerospace-grade heat treatment)

Featured Capabilities:

ASTM B564 flanges: Solution-annealed per AMS 5662 (Inconel 718)

NACE MR0175 compliance: Guaranteed SSC resistance at H₂S partial pressures >0.3 psi

Medical polish: Ra ≤ 0.2μm surface finish for ISO 13485 applications

Key Features

Smooth surface finish up to Ra ≤ 0.2μm, meeting medical and semiconductor standards

Available in a variety of nickel alloys and customized surface treatments

Leak-proof Design: Blind flanges provide secure sealing for pipeline termination.

Custom Finishes: Available in polished (Ra ≤ 0.8μm), sandblasted, or coated surfaces.

Standards Compliance: ASTM B564 (forged), ASME B16.5/B16.47 (dimensions).

Applications

Our flanges are trusted in industries with zero tolerance for failure

Aerospace

High-temperature turbine systems, structural sealing

01

Petrochemical & Energy

Pipeline ends, reactor closures

02

Semiconductors

Ultra-clean gas pipelines with EP-grade finish

03

Marine & Offshore

Seawater systems, anti-corrosion barrier ends

04

Production and Processing Technology

We combine advanced CNC machining and strict alloy handling protocols. Our manufacturing processes ensure:

- Ultra-tight tolerance control

- Custom surface processing like pickling, passivation, and electropolishing (EP)

- Welded or forged options, depending on pressure and sealing needs

- 100% PMI (Positive Material Identification) before dispatch

Nickel Alloy BL Flange Production Process

-

Raw Material Selection – From certified nickel alloy stock (strategic reserve).

-

Forging or Machining – Based on size, pressure class, and customization.

-

Heat Treatment – For mechanical stability and corrosion resistance.

-

Precision Finishing – Includes optional EP or medical-grade polishing.

-

Quality Inspection – Each piece undergoes 100% dimensional and chemical testing.

-

Marking & Packaging – Heat No., alloy grade, and specs are marked for traceability.

Quality Inspection

Every Nickel Alloy BL Flange is inspected by professional inspectors. Our checks include:

- Visual and dimensional inspection

- ASTM-compliant mechanical testing

- Surface finish check (Ra inspection)

- PMI (XRF spectroscopy)

- Certification: ISO 9001, ISO 13485, AS9100D, NADCAP (as needed)

After placing an order, we will provide: QAC/ITP/MTR

Our Service

Global Supply Chain

With 14 years of trading, we ensure on-time international delivery.

Precision Manufacturing:

Tight-tolerance machining and custom surfaces like sandblasting, pickling, polishing — tailored for medical and chemical use.

Complete Quality System

Certified under ISO 9001, ISO 13485 (medical), AS9100D (aerospace), NADCAP (heat treatment) for full compliance.

Delegati Curatores

Traceability System: All flanges are heat-number tracked and supplied with full documentation.

Advanced Alloy Purity Control

We use high-purity raw materials and strict refining to ensure performance under extreme conditions.

Fast Response to Custom Needs

Small batch or urgent order? We adapt quickly.

Package and Shipping

FAQ

Q: Can you supply medical-grade flanges?

A: Yes, with ISO 13485 certification and Ra ≤ 0.2μm polished finish.

Q: Do you accept small batch or urgent orders?

A: Absolutely. We have strategic stock and flexible production capacity.

Q: Can you provide test reports?

A: All products come with MTC, third-party test reports available on request.

Contact Us

Let's start your project with high-performance Nickel Alloy BL Flange from TSM. Email: info@tsmnialloy.com

Learn about our latest products and discounts through SMS or email

Learn about our latest products and discounts through SMS or email