- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

Application of Nickel Alloys in Aerospace

Aerospace engineering, as one of the most advanced industrial fields, requires high-performance and excellent materials. Nickel alloys have become indispensable materials in the aerospace industry with their excellent strength, corrosion resistance, high temperature resistance and other properties.

Nickel-based alloys are the main materials for manufacturing high-temperature engine components, such as turbine blades, combustion chamber liners and exhaust nozzles. These components require high temperature resistance, high mechanical strength and good fatigue resistance. Nickel-based alloys can meet these requirements and ensure the performance and reliability of the engine.

The high temperature resistance of nickel alloys ensures the high efficiency and reliability of aviation engines, enabling them to work under extreme conditions. The excellent corrosion resistance of nickel alloys prevents these components from being damaged by harsh environments such as salt water and acidic gases, thus helping to ensure the safety and life of aircraft.

Aerospace Industry

Commonly Used Nickel Alloy Grades & Product Forms

| Product Form |

Common Grades |

Typical Aerospace Applications |

|---|---|---|

| Plate / Sheet |

Inconel 718 |

Engine structural parts, turbine components |

|

Inconel 625 |

Exhaust systems, heat shields | |

|

Inconel 600 |

High-temperature structural components | |

|

Hastelloy X |

Combustion chambers, hot section parts | |

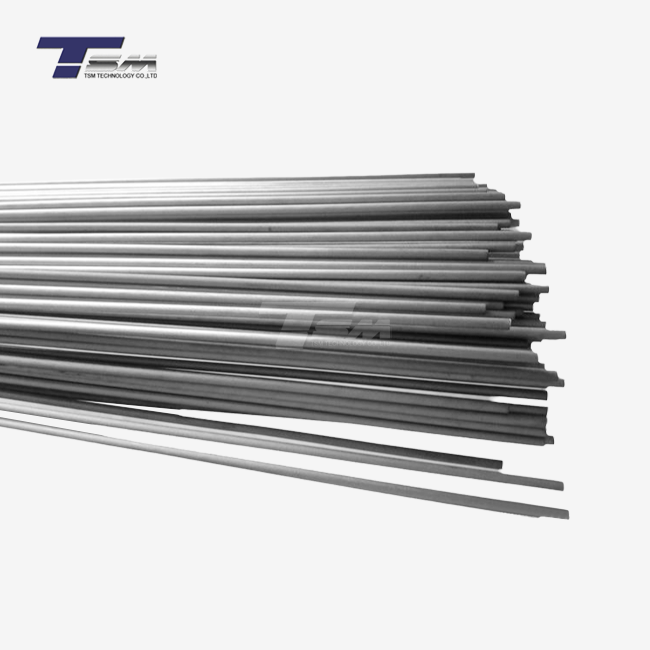

| Bar / Rod |

Inconel 718 |

Shafts, turbine disks, fastener blanks |

|

Inconel 625 |

High-strength machined components | |

|

A286 |

Bolts, high-temperature fasteners | |

| Tube / Pipe (Seamless) |

Inconel 625 |

Fuel lines, hydraulic systems |

|

Inconel 718 |

High-pressure, high-temperature tubing | |

|

Inconel 600 |

Thermal and exhaust tubing | |

| Strip / Foil |

Nickel 200 / 201 |

Sensors, electrical and shielding components |

| Wire |

Nickel 200 / 201 |

Thermocouples, electrical conductors |

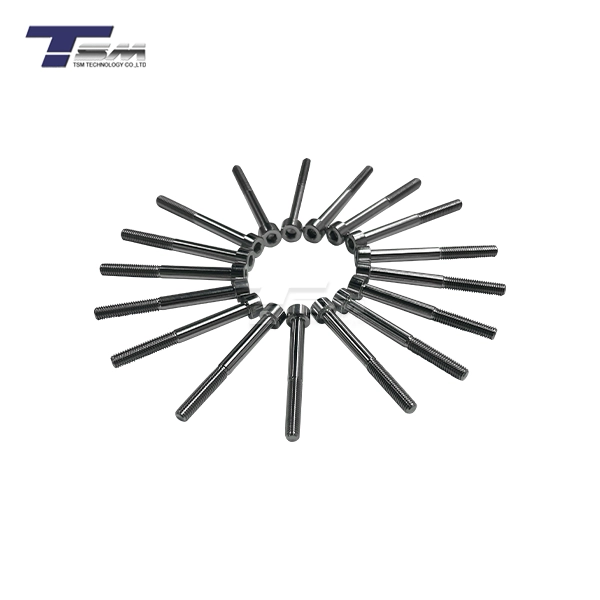

| Fasteners |

Inconel 718 |

Engine and hot-section fasteners |

|

A286 |

Structural and turbine fasteners |

Key Aerospace Material Characteristics

-

High-temperature strength and creep resistance

-

Oxidation and fatigue resistance

-

Lightweight, high strength-to-weight ratio

-

Compliance with AMS / AS9100 requirements

Nickel Alloys for Aerospace

|

Nickel |

|

|

Nickel 200 |

Nickel 201 |

|

MONEL ALLOY |

||||

|

ALLOY 400 |

ALLOY 401 |

ALLOY 404 |

ALLOY K500 |

ALLOY 502 |

|

INCONEL ALLOY |

||||

|

ALLOY 600 |

ALLOY 601 |

ALLOY 602CA |

ALLOY 617 |

ALLOY 625 |

|

INCONEL 686 |

690 |

718 |

725 |

X-750 |

|

INCOLOY ALLOY |

||||

|

800/800H/800HT |

801 |

825 |

925 |

926 |

|

A-286 |

ALLOY 20 |

ALLOY 75 |

ALLOY 33 |

ALLOY 31 |

|

ALLOY 28 |

ALLOY 330 |

|

|

|

|

HASTELLOY ALLOY |

||||

|

B |

B2 |

B3 |

C |

C59 |

|

C4 |

C22 |

C276 |

C2000 |

G30 |

|

G35 |

X |

|

|

|

|

High Temperature alloy |

||||

|

GH3030 |

GH3128 |

GH3044 |

GH3039 |

GH4080A |

|

4J50 |

4J29 kovar |

4J42 |

4J36 |

3J01 |

|

1J79 |

|

|

|

|

|

Copper alloy |

||||

|

C70600 |

C68700 |

C86300 |

C71500 |

C86300 |

Contact Us

For high-quality products and expert technical support, contact us today:

Email: info@tsmnialloy.com

Learn about our latest products and discounts through SMS or email