- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

Nickel alloys in gas and oil applications

Nickel alloys are widely used in the oil and gas industry due to their excellent corrosion resistance, high temperature strength, and toughness. Their unique properties make them ideal for critical applications that require durability and reliability under extreme conditions.

In the production of oil and gas, nickel alloys are primarily used in the construction and maintenance of drilling equipment, pipelines, and tanks. These alloys are essential for preventing corrosion of metal parts that come into contact with corrosive fluids and gases. Nickel alloys also offer longer service life and lower maintenance requirements due to enhanced resistance to stress corrosion cracking.

In addition, nickel alloys have become common in the manufacture of heaters, furnaces, and heat exchangers used in crude oil and natural gas refining and processing. These components are subject to extreme temperatures and harsh environments, making the use of nickel alloys essential. Nickel alloys have low thermal expansion and excellent thermal conductivity, allowing them to efficiently transfer heat and withstand thermal cycling, which are essential properties in these applications.

Oil & Gas Industry

Commonly Used Nickel Alloy Grades & Product Forms

|

Product Form |

Common Grades | Typical Oil & Gas Applications |

|---|---|---|

| Seamless Tube / Pipe |

Inconel 625 |

Flowlines, control lines, subsea piping |

|

Incoloy 825 |

Sour gas service, corrosion-resistant piping | |

|

Hastelloy C276 |

Severe acid and sour environments | |

|

Inconel 718 |

HPHT well tubing, downhole tools | |

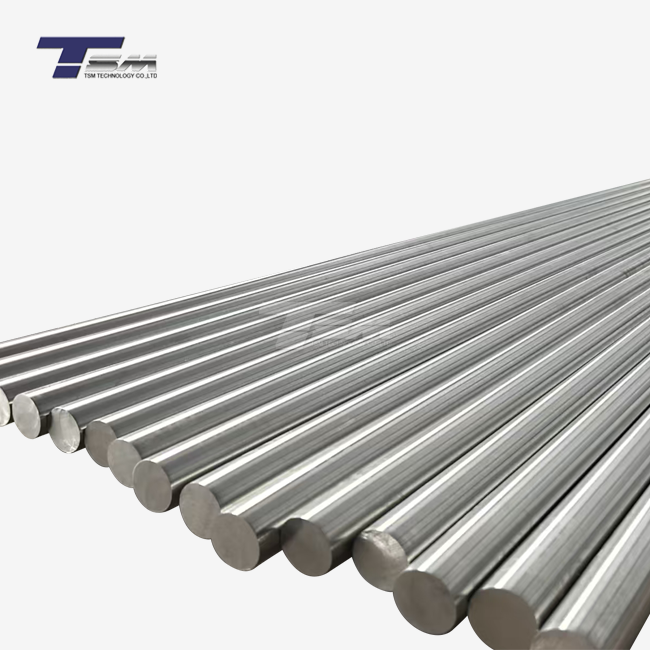

| Bar / Rod |

Inconel 718 |

Downhole tools, pressure-bearing parts |

|

Inconel 725 |

Valve stems, high-strength fasteners | |

|

Monel K500 |

Offshore shafts, valve components | |

| Plate / Sheet |

Inconel 625 |

Pressure vessels, heat exchangers |

|

Incoloy 825 |

Desulfurization units, process equipment | |

|

Hastelloy C276 |

Reactors, highly corrosive systems | |

| Fasteners |

Inconel 718 |

High-pressure flange connections |

|

Inconel 725 |

Sour-service bolting | |

|

Monel K500 |

Offshore structural connections | |

| Wire / Strip |

Nickel 200 / 201 |

Instrumentation, auxiliary components |

Key Oil & Gas Material Characteristics

-

Resistance to H₂S / CO₂ (sour service)

-

High strength under high pressure and high temperature (HPHT)

-

Compliance with NACE MR0175 / ISO 15156

-

Long-term reliability in offshore and onshore environments

Contact Us

For high-quality products and expert technical support, contact us today:

Email: info@tsmnialloy.com

Learn about our latest products and discounts through SMS or email