- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

Application of Nickel Alloys in Heat Treatment

Heat treatment is a key process for nickel alloys, heating and cooling the metal to a specific temperature to change its microstructure and improve its strength and toughness. Making it one of the ideal alloy material choices for end conditions.

Nickel alloys are often used in annealing processes due to their high ductility and easy processing. This makes them very suitable for manufacturing a variety of products, including wires, plates and pipes. In addition, nickel alloys are also suitable for quenching and tempering processes, which can increase the hardness and strength of the material.

The use of nickel alloys in heat treatment processes has been fully proven and verified. Our materials have undergone various practical tests and have shown excellent performance, making them the first choice for many customers.

Heat Treatment Industry

Commonly Used Nickel Alloy Grades & Product Forms

| Product Form |

Common Grades |

Typical Applications |

|---|---|---|

| Tube / Pipe |

Inconel 600 |

Furnace tubes, radiant tubes |

|

Inconel 601 |

High-temperature furnace components | |

| Plate / Sheet |

Inconel 601 |

Furnace linings, trays |

|

Hastelloy X |

High-temperature shields | |

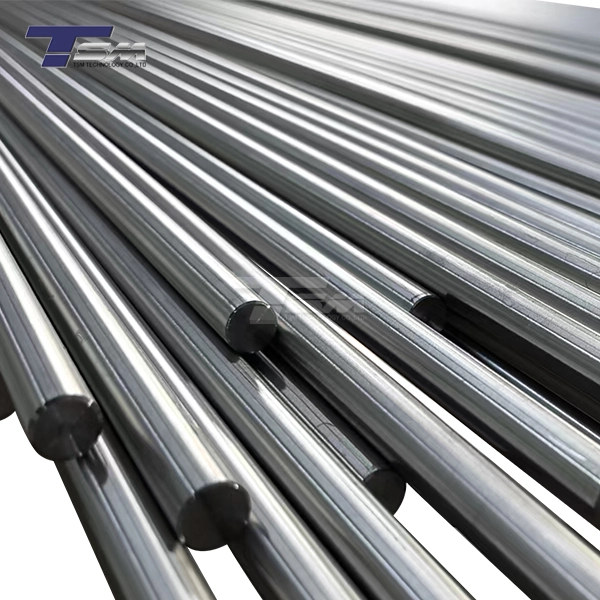

| Bar / Rod |

Inconel 601 |

Furnace fixtures, supports |

|

Inconel 600 |

Structural components | |

| Wire / Strip |

Nickel 200 |

Heating elements, resistance components |

Nickel alloys for hot working

|

High Temperature alloy |

||||

|

GH3030 |

GH3128 |

GH3044 |

GH3039 |

GH4080A |

|

4J50 |

4J29 kovar |

4J42 |

4J36 |

3J01 |

|

1J79 |

|

|

|

|

Contact Us

For high-quality products and expert technical support, contact us today:

Email: info@tsmnialloy.com

Learn about our latest products and discounts through SMS or email