- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

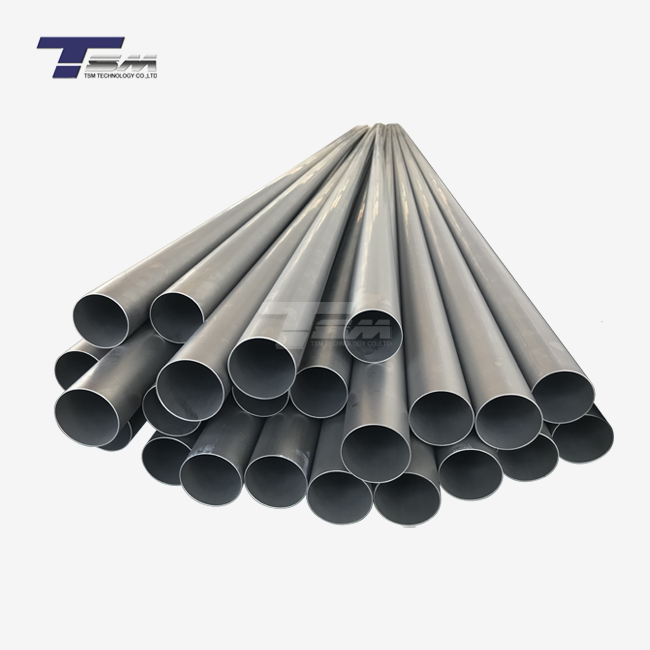

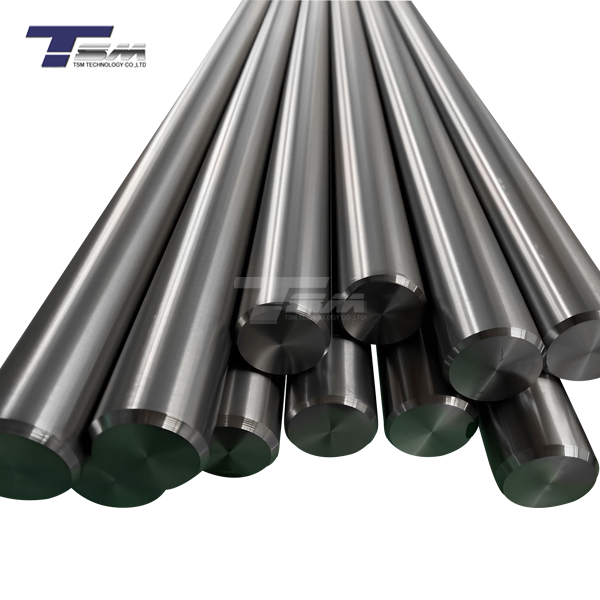

C276 Pipe Fittings

3 factories * 8 production lines * 100+ machines

Supply Ability: 200 Tons/month

Grade: Alloy C276 (UNS No. N10276)

Standard: ASTM, JIS, AISI, GB, DIN, EN

Type: Elbow, Tee, Reducer, Stub End, Cap, Cross

Size: 1/2” to 24” (DN15–DN600)

Wall Thickness: SCH10 to SCH160

Form: Seamless / Welded Pipe Fittings

Customization and processing supported

Material Certification: MTC and SGS test reports available

Delivery Time: Usually about 10–25 days

Not for Private Person Sale

C276 Pipe Fittings - Superior Corrosion Resistance for Critical Applications

When your mechanical operations require extraordinary chemical resistance and high-temperature execution, C276 pipe fittings provide unmatched unwavering quality. These premium Hastelloy C276 fittings give prevalent assurance against forceful chemicals, making them fundamental for basic channeling frameworks in chemical handling, petrochemical, and control era businesses. With exceptional resistance to setting, stress-corrosion cracking, and warm corrosion, C276 pipe fittings guarantee secure, long-lasting associations in your most demanding applications.

What are the C276 Pipe Fittings?

C276 pipe fittings are high-performance components made from Hastelloy C276, a nickel-molybdenum-chromium superalloy. These fittings interface, control, and divert liquid streams in channeling frameworks exposed to destructive situations and extraordinary temperatures. The one-of-a-kind composition of these fittings incorporates critical amounts of molybdenum and chromium, giving uncommon resistance to both oxidizing and decreasing chemical situations. You'll discover these fittings irreplaceable when standard materials fall flat beneath cruel working conditions.

Specification

| Parameter | Details |

|---|---|

| Grade | Alloy C276 (UNS No. N10276) |

| Standard | ASTM B366, JIS, AISI, GB, DIN, EN |

| Type | Elbow, Tee, Reducer, Stub End, Cap, Cross |

| Size Range | 1/2" to 24" (DN15–DN600) |

| Wall Thickness | SCH10 to SCH160 |

| Form | Seamless / Welded Pipe Fittings |

| Connection Type | Butt Weld, Socket Weld, Threaded |

| Pressure Rating | Class 150 to Class 2500 |

| Temperature Range | Up to 1,900°F (1,038°C) |

Physical and Chemical Properties

| Property | Value |

|---|---|

| Density | 8.89 g/cm³ |

| Melting Point | 1,370°C (2,500°F) |

| Tensile Strength | 690 MPa min |

| Yield Strength | 283 MPa min |

| Elongation | 40% min |

| Hardness | ≤ 22 HRC |

| Nickel Content | 54-58% |

| Molybdenum Content | 15-17% |

| Chromium Content | 14.5-16.5% |

| Tungsten Content | 3-4.5% |

Product Standards

Our fittings comply with multiple international standards to ensure global compatibility:

- ASTM B366 - Standard determination for factory-made nickel and nickel amalgam fittings

- ASME B16.9 - Factory-made buttwelding fittings

- ASME B16.11 - Fashioned fittings, socket-welding and threaded

- MSS SP-43 - Fashioned stainless steel butt-welding fittings

- DIN 2605 - German standard for pipe fittings

What are the features of the product?

Your operations demand the best, and these fittings deliver exceptional features:

- Outstanding Erosion Resistance: Prevalent security against sulfuric corrosive, hydrochloric corrosive, and chloride environments

- High Temperature Execution: Keeps up quality and steadiness at hoisted temperatures up to 1,900°F

- Excellent Weldability: Simple to create and introduce without compromising integrity

- Stress Erosion Splitting Resistance: Avoids disappointment in high-stress environments

- Low Carbon Substance: Minimizes carbide precipitation for upgraded erosion resistance

Application

C276 Pipe Fittings serve critical roles across demanding industries:

- Chemical Handling: Taking care of forceful chemicals and acidic solutions

- Petrochemical Industry: Refining operations and hydrocarbon processing

- Marine Building: Seawater frameworks and seaward platforms

- Power Era: Atomic and warm control plant applications

- Pharmaceutical Fabricating: Sterile and destructive environment processing

- Pulp and Paper Industry: Dying and chemical recuperation systems

Production and Processing Technology

At TSM Innovation, we utilize progressed fabricating procedures to guarantee superior quality. Our state-of-the-art office utilizes accuracy-producing, machining, and shaping forms. Each fitting experiences controlled warm treatment to optimize mechanical properties and erosion resistance.

What is the production process of the product?

Our comprehensive production process ensures consistency and quality:

- Raw Fabric Review: Confirmation of chemical composition and fabric certificates

- Hot Shaping: Exactness manufacturing to accomplish wanted shapes and dimensions

- Heat Treatment: Arrangement toughening at ideal temperatures

- Machining: CNC accuracy machining for correct specifications

- Surface Treatment: Pickling and passivation for upgraded erosion resistance

- Quality Testing: Comprehensive dimensional and mechanical property verification

- Final Assessment: Total documentation and certification preparation

Quality Inspection

Every fitting undergoes rigorous quality control:

- Chemical Composition Examination: Spectroscopic verification

- Mechanical Testing: Ductile quality and hardness evaluation

- Dimensional Review: Exact estimation verification

- Non-Destructive Testing: Ultrasonic and color penetrant testing

- Hydrostatic Testing: Weight astuteness validation

- Corrosion Testing: Fabric execution verification

Why choose TSM Technology?

With over 14 years of experience and sending out to 70+ nations, TSM Innovation stands as your trusted accomplice. Our 50,000㎡ cutting edge production line houses 100+ accuracy machines over 8 generation lines, conveying 200 tons a month to a capacity. We keep up ISO 9001, AS9100D, and AS9120 certifications, guaranteeing aerospace-grade quality guidelines for each product.

Company Exhibition

TSM Innovation frequently takes an interest in worldwide trade shows, displaying our most recent advancements and interacting with worldwide accomplices. These occasions illustrate our commitment to industry headway and client benefit excellence.

Package and Shipping

We ensure safe delivery through professional packaging:

- Individual Security: Each fitting is wrapped in defensive material

- Wooden Cartons: Strong bundling for universal shipping

- Documentation: Total fabric certificates and test reports

- Delivery Time: Standard 10-25 days depending on amount and specifications

FAQ

Q1: What is the greatest temperature these items can withstand?

A: Our C276 fittings can handle ceaseless operation at temperatures up to 1,900°F (1,038°C), making them perfect for high-temperature applications.

Q2: Can these fittings be utilized for high-pressure applications?

A: Completely! Our fittings are outlined and tried for high-pressure frameworks, with weight evaluations from Course 150 to Lesson 2500.

Q3: What certifications do your fittings come with?

A: Each shipment incorporates Fabric Test Certificates (MTC), Process Test Reports (MTR), and third-party review certificates when required.

Q4: Do you offer custom sizes and specifications?

A: Yes, we give comprehensive customization services to meet your particular venture requirements, counting non-standard measurements and uncommon configurations.

Q5: How do you guarantee the quality of your product?

A: We keep up strict quality control through certified testing research facilities, experienced quality engineers, and compliance with universal measures counting ASTM B366 and ASME B16.9.

Contact Us

Ready to enhance your project with premium C276 Pipe Fittings? Our technical experts are standing by to assist with your specific requirements. Contact us today at info@tsmnialloy.com for detailed quotations, technical specifications, and professional consultation. Let TSM Technology be your trusted partner for superior alloy solutions.

Learn about our latest products and discounts through SMS or email

Learn about our latest products and discounts through SMS or email