- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

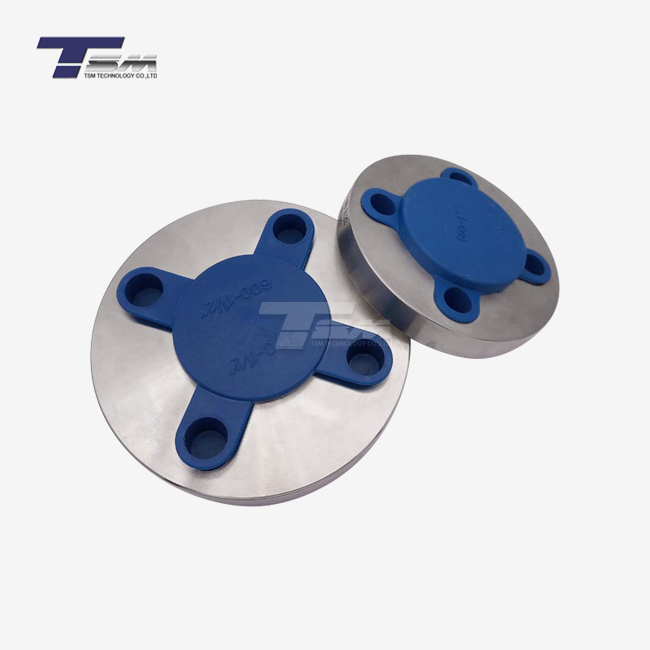

Hastelloy C276 Fittings

Supply Ability: 200 Tons/month

Grade: Hastelloy C276 (UNS No. N10276)

Standard: ASTM, JIS, AISI, GB, DIN, EN

Size: 1/2” to 24” (DN15–DN600)

Wall Thickness: SCH10 to SCH160

Form: Seamless / Welded Pipe Fittings

Customization and processing supported

Material Certification: MTC and SGS test reports available

Delivery Time: Usually about 10–25 days

Provide Free Sample

Not for Private Person Sale

Hastelloy C276 Fittings - Premium Corrosion-Resistant Solutions

When you need superior performance in the most demanding chemical environments, Hastelloy C276 Fittings deliver unmatched reliability. These premium nickel-molybdenum-chromium amalgam fittings give uncommon resistance to both common and localized erosion, making them your perfect choice for basic mechanical applications. Our C276 fittings keep up astuteness beneath extraordinary temperatures and chemicals, guaranteeing secure, proficient framework operation for years.

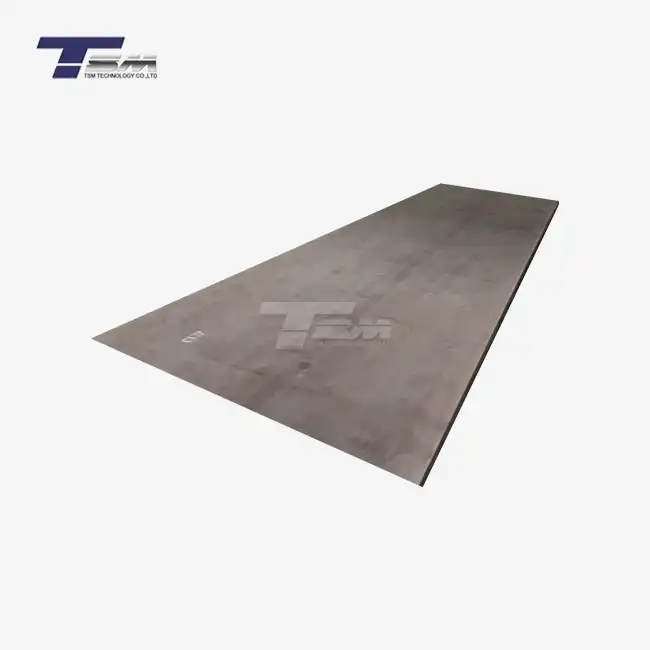

The items are pipe connectors made from a high-performance nickel-molybdenum-chromium superalloy, outlined for destructive situations. C276 combination stands up to acids, chlorides, and chemicals, while advertising fabulous mechanical properties at high temperatures.

Specification

| Parameter | Details |

|---|---|

| Grade | Hastelloy C276 (UNS N10276) |

| Size Range | 1/2" to 24" (DN15–DN600) |

| Wall Thickness | SCH10 to SCH160 |

| Form | Seamless / Welded Pipe Fittings |

| Standard | ASTM, JIS, AISI, GB, DIN, EN |

| Manufacturing | ASTM B366, UNS N10276 |

| Supply Capacity | 200 Tons/month |

| Delivery Time | 10–25 days |

| Customization | Available upon request |

Physical and Chemical Properties

| Property | Value |

|---|---|

| Density | 8.89 g/cm³ |

| Melting Point | 1325-1370°C (2417-2498°F) |

| Tensile Strength | 690 MPa (100 ksi) min |

| Yield Strength | 283 MPa (41 ksi) min |

| Elongation | 40% min |

| Hardness | ≤ 22 HRC |

| Nickel Content | 54-58% |

| Molybdenum Content | 15-17% |

| Chromium Content | 14.5-16.5% |

| Maximum Service Temperature | 1038°C (1900°F) |

Product Standards

Our C276 fittings comply with universally recognized measures counting ASTM B366, UNS N10276, ASME B16.9, and EN 10253-4. These certifications guarantee reliable quality and execution across all applications. We keep up strict adherence to ISO 9001, AS9100D, and AS9120 quality administration systems.

Production and Processing Technology

TSM Innovation utilizes progressed fabricating strategies counting exactness manufacturing, CNC machining, and thermal treatment processes.

Our progressed hardware guarantees dimensional exactness, predominant wraps up, and maintains combination properties through controlled dissolving and shaping processes.

What is the production process of the product?

- Raw Material Selection: High-purity C276 alloy sourcing and verification

- Melting and Casting: Controlled atmosphere melting for optimal composition

- Hot Forging: Precision forming to achieve desired shapes and grain structure

- Heat Treatment: Solution annealing for stress relief and property optimization

- Machining: CNC processing for precise dimensions and surface finish

- Quality Testing: Comprehensive inspection including dimensional and material testing

- Final Inspection: Documentation and certification before packaging

Quality Inspection

Our comprehensive quality control system includes ultrasonic testing, radiographic examination, eddy current testing, and hydrostatic pressure testing. Each fitting undergoes verification, inspection, and material analysis, with full traceability documentation, including MTC and SGS reports.

What are the highlights of the product?

Exceptional Erosion Resistance: Prevalent security against acids, chlorides, and oxidizing environments

High-Temperature Execution: Keeps up quality and astuteness up to 1900°F (1038°C)

Excellent Weldability: Simple establishment without compromising fabric properties

Stress-Corrosion Breaking Resistance: Anticipates disappointment beneath mechanical stress and destructive conditions

Versatile Setup: Accessible in flanged, strung, and compression designs

Long Benefit Life: Diminishes upkeep costs and framework downtime

Application

Hastelloy C276 Fittings find extensive use across multiple industries. These fittings are fundamental in chemical preparation, petrochemical refineries, marine applications, aviation fuel systems, and control era, advertising unwavering quality in taking care of forceful chemicals, high temperatures, weights, seawater erosion, and turbine applications.

Factory

Our fabricating office ranges 50,000 square meters with three specialized generation regions committed to distinctive combination preparation requirements.

Advanced hardware like vacuum acceptance heaters and mechanized review frameworks guarantees tight resistances and meets requesting generation schedules.

Why Choose TSM Technology?

With over 14 years of involvement and trades to 70+ nations, TSM Innovation stands as your trusted accomplice for premium amalgam arrangements. Our 50,000㎡ square foot office with 100+ exactness machines guarantees quality, convenient conveyance, and AS9100D certification for aviation projects.

Package and Shipping

We employ protective packaging methods including individual wrapping, foam cushioning, and moisture-resistant barriers. Standard shipping containers ensure safe international transport. Our Hong Kong logistics hub facilitates efficient global distribution with tracking capabilities and insurance coverage.

FAQ

Q: Can these fittings be utilized in submerged installations?

A: Yes, the C276 combination offers fabulous resistance to seawater erosion, making it perfect for marine and submerged applications.

Q: What is the most extreme temperature these fittings can handle?

A: Our C276 fittings can withstand persistent benefit temperatures up to 1900°F (1038°C).

Q: Are custom sizes and setups available?

A: Completely. We give customization services for uncommon measurements, threading, and arrangement requirements.

Q: How long is the normal conveyance time?

A: Standard conveyance time ranges from 10-25 days depending on arrange amount and specifications.

Q: Do you give fabric certificates and test reports?

A: Yes, we supply total documentation counting Fabric Test Certificates (MTC), SGS reports, and dimensional review certificates.

Q: What payment terms do you offer?

A: We accept various payment methods including T/T, L/C, and other internationally recognized payment terms.

Contact Us

Ready to enhance your system's performance with premium Hastelloy C276 Fittings? Contact our technical team for expert advice, competitive pricing, and reliable, long-term solutions for your challenging applications.

Email: info@tsmnialloy.com

Request your free sample today and experience the TSM Technology difference firsthand.

Learn about our latest products and discounts through SMS or email

Learn about our latest products and discounts through SMS or email

_1739071581132.webp)