- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

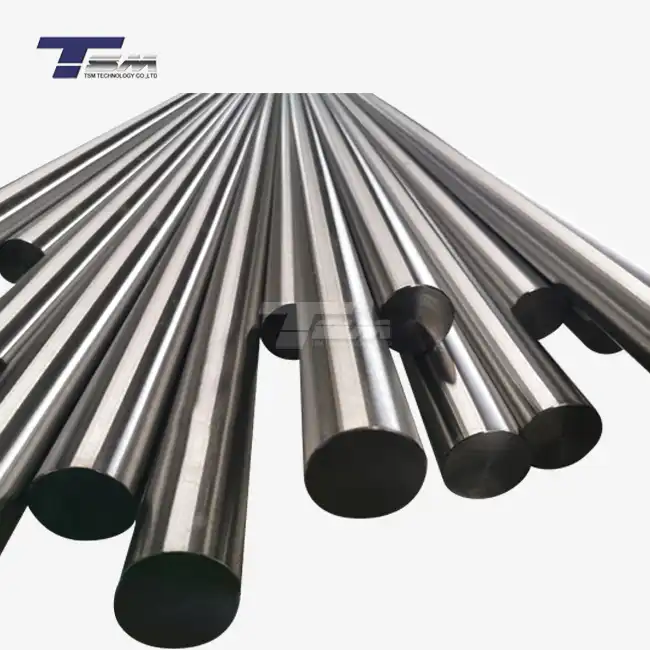

Hastelloy C276 Tube

Standard:ASTM B622、ASTM B619、ASTM B626

Outside Diameter:6.0-114 mm

Wall Thickness:0.5-15 mm

Length:Max.15000mm (the maximum length is for the scope of special diameters and walls)

Customized size and processing are supported

Trusted Manufacturer & Supplier of Hastelloy C276 Tube

TSM Technology is a leading hastelloy tubing manufacturer and supplier, dedicated to providing superior nickel alloy solutions to various industries. Our product offers exceptional corrosion resistance, high durability, and precision engineering, making it the ideal choice for demanding environments.

What is the Hastelloy C276 Tube?

Hastelloy C276 Tube is a nickel-molybdenum-chromium alloy known for its outstanding resistance to severe corrosive environments, including strong oxidizing and reducing agents. This alloy is widely used in industries such as chemical processing, marine, aerospace, and power plants due to its superior mechanical properties and longevity. With excellent weldability and stress corrosion resistance, it is ideal for applications requiring durability and performance under extreme conditions.

Supply Type

Hastelloy C276 pipe supply includes seamless pipes and welded pipes, which can be manufactured by cold drawing or hot rolling process, and provide surface treatments such as pickling, bright annealing, polishing, etc. It complies with ASTM B622, ASTM B619 and other standards, and is widely used in chemical, marine and highly corrosive environments.

Specifications

OD: φ6 - φ114mm

WT: 0.5 - 15mm

L ≤ 12000mm

Please confirm with us for customized sizes

Product Standards

Our hastelloy tubing complies with the following international standards:

Seamless: ASTM B622

Welded: ASTM B619, ASTM B626

Hastelloy C-276(UNS N10276W.Nr.2.4819/NS336) |

||||||||||||||||

|

Chemical Composition |

Alloy |

% |

Ni |

Cr |

Fe |

Mo |

C |

Mn |

Si |

S |

P |

Co |

V |

W |

||

|

Hastelloy C |

min |

margin |

14.5 |

4 |

15 |

|

|

|

|

|

|

|

3 |

|||

|

|

max |

margin |

16.5 |

7 |

17 |

0.08 |

1 |

1 |

0.03 |

0.04 |

2.5 |

0.35 |

4.5 |

|||

|

C276 |

min |

margin |

14.5 |

4 |

15 |

|

|

|

|

|

|

|

3 |

|||

|

|

max |

margin |

16.5 |

7 |

17 |

0.01 |

1 |

0.08 |

0.03 |

0.04 |

2.5 |

0.35 |

4.5 |

|||

|

Physical Characteristics |

Density |

8.9g/cm³ |

||||||||||||||

|

Melting point |

1325-1370℃ |

|||||||||||||||

|

Minimum mechanical properties of alloys at room temperature |

Typical mechanical properties |

tensile strength Rm N/mm² |

Yield Strength RP0.2 N/mm² |

Elongation A5% |

Brinell hardness HB |

|||||||||||

|

Solution treatment |

690 |

283 |

40 |

|||||||||||||

Product Details

Material Characteristics

Superior Corrosion Resistance: Withstands oxidizing and reducing environments, including acidic and chloride conditions.

High-Temperature Strength: Performs well in extreme heat and harsh chemical processes.

Excellent Weldability: Easily welded without risk of grain boundary precipitation.

Non-Magnetic: Ideal for sensitive applications requiring non-magnetic properties.

Low Carbon Content: Minimizes carbide precipitation, ensuring long-term performance.

Applications of Hastelloy C276 Tube

Chemical Processing: Used in heat exchangers, reactors, and piping systems.

Marine Industry: Ideal for seawater applications due to exceptional corrosion resistance.

Aerospace & Defense: Utilized in aircraft exhaust and fuel systems.

Power Plants: Applied in nuclear and geothermal energy production.

Medical Equipment: Ensures biocompatibility and longevity in critical devices.

Hastelloy C276 Pipe vs Hastelloy C22 Tube: Key Differences

| Comparison Criteria | Hastelloy C276 Pipe (UNS N10276) | Hastelloy C22 Tube (UNS N06022) |

|---|---|---|

| Primary Composition | Ni-16%Mo-16%Cr-4%W | Ni-22%Cr-13%Mo-3%W |

| Key Strength | Superior chloride resistance | Enhanced oxidizing acid resistance |

| Corrosion Resistance | Excellent for reducing acids (HCl, H₂SO₄) | Better for mixed acids (HCl+HNO₃) & pitting |

| Temperature Limit | Up to 1093°C (2000°F) | Up to 1204°C (2200°F) |

| Common Applications | Chemical processing, marine environments | Pharmaceutical, pollution control systems |

| Form Availability | Seamless & welded pipes (ASTM B619) | Seamless & welded tubes (ASTM B622) |

| Cost Factor | Generally lower cost | Premium priced (20-25% higher) |

| Weldability | Good (but may need post-weld treatment) | Excellent (lower sensitization risk) |

Testing Process and Equipment

Why Choose Us?

Customized solutions

including size, wall thickness, surface treatment, processing technology, etc.

Full quality control

100% hydrostatic pressure test, each tube is traceable.

Processing services

Provide cutting, welding, bending and other special processing needs.

Global supply

Products have been sold to more than 60 countries around the world.

Packaging and shipment

FAQ

Q1: What makes it unique?

A1: It is highly resistant to corrosion, stress, and oxidation, making it ideal for extreme environments.

Q2: Can TSM provide customized tube dimensions?

A2: Yes, we offer a variety of sizes and can manufacture tubes to your exact specifications.

Q3: Do you provide material certifications?

A3: Absolutely. All our Hastelloy C276 pipes come with detailed test reports and quality certifications.

Q4: How do I place an order?

A4: Contact us via email at [info@tsmnialloy.com] for inquiries and quotes.

Contact Us

For bulk orders or specific inquiries about Hastelloy C276 Tube, reach out to us

Email: info@tsmnialloy.com

Learn about our latest products and discounts through SMS or email

Learn about our latest products and discounts through SMS or email