- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

3 Applications of Inconel Alloys

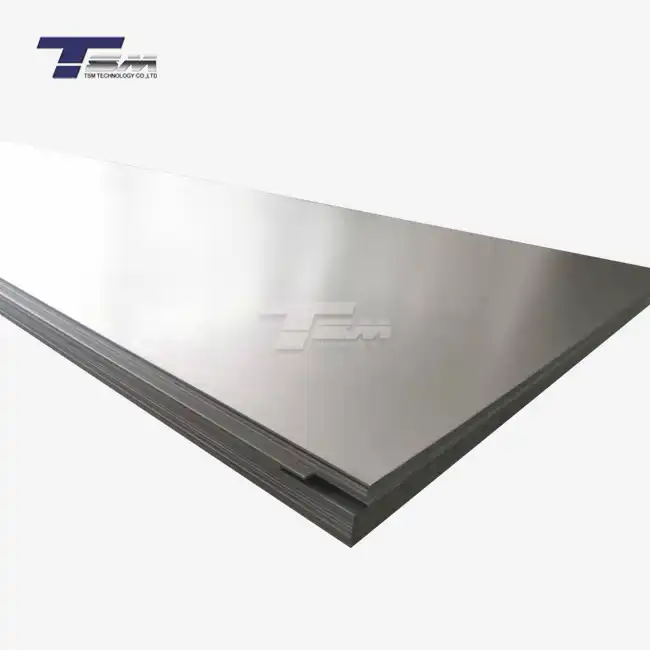

Inconel alloys, renowned for their exceptional strength and corrosion resistance, have become indispensable in various high-performance industries. These nickel-chromium-based superalloys excel in extreme environments, making them ideal for aerospace, chemical processing, and energy production. The three primary applications of Inconel alloys include gas turbine components in aircraft engines, heat exchangers in chemical plants, and reactor vessels in nuclear power facilities. Their ability to maintain structural integrity under high temperatures and pressures, coupled with outstanding resistance to oxidation and corrosion, makes Inconel alloys the material of choice for demanding industrial applications.

Aerospace Industry: Soaring to New Heights with Inconel Alloys

Jet Engine Components: The Heart of Modern Aviation

In the aerospace industry, Inconel alloys play a crucial role in manufacturing jet engine components. These superalloys are extensively used in turbine blades, combustion chambers, and exhaust systems. The extreme conditions inside a jet engine, with temperatures reaching up to 1,300°C and enormous mechanical stresses, demand materials that can withstand such harsh environments. Inconel alloys, with their exceptionally high-temperature strength and resistance to thermal fatigue, meet these demanding requirements.

The use of Inconel alloys in turbine blades allows aircraft engines to operate at higher temperatures, resulting in improved fuel efficiency and increased thrust-to-weight ratios. These alloys also contribute to the longevity of engine components, reducing maintenance costs and improving overall reliability. As the aerospace industry continues to push the boundaries of performance and efficiency, Inconel alloys remain at the forefront of materials technology.

Rocket Propulsion Systems: Powering Space Exploration

Beyond commercial aviation, Inconel alloys find extensive use in rocket propulsion systems. The extreme temperatures and corrosive environments encountered during rocket launches necessitate materials that can maintain their integrity under such conditions. Inconel alloys are used in rocket nozzles, thrust chambers, and fuel injection systems, where their resistance to high-temperature oxidation and excellent strength properties are invaluable.

In the rapidly evolving field of space exploration, where every gram of weight matters, the superior strength-to-weight ratio of Inconel alloys makes them an ideal choice for rocket components. Their ability to resist creep at high temperatures ensures the structural integrity of critical components during the intense heat and pressure of rocket launches.

Aircraft Exhaust Systems: Enhancing Performance and Durability

Inconel alloys are also extensively used in aircraft exhaust systems. These components are subjected to extreme temperatures, corrosive gases, and thermal cycling. The superior oxidation resistance and thermal stability of Inconel alloys make them ideal for exhaust manifolds, tailpipes, and afterburner components.

By using Inconel alloys in exhaust systems, aircraft manufacturers can reduce weight while improving durability and performance. The alloys' resistance to high-temperature corrosion helps prevent degradation of exhaust components, extending their service life and reducing maintenance requirements. This application of Inconel alloys contributes significantly to the overall efficiency and reliability of modern aircraft.

Chemical Processing: Revolutionizing Industrial Operations with Inconel Alloys

Heat Exchangers: Optimizing Thermal Efficiency

In the chemical processing industry, Inconel alloys have become the material of choice for heat exchangers operating in corrosive and high-temperature environments. These alloys excel in applications where traditional materials like stainless steel or copper alloys would quickly degrade. The exceptional corrosion resistance of Inconel alloys, particularly to chloride stress corrosion cracking, makes them ideal for use in seawater-cooled heat exchangers and in processes involving aggressive chemicals.

Inconel alloy heat exchangers offer superior thermal conductivity and maintain their strength at elevated temperatures, allowing for more efficient heat transfer in demanding industrial processes. Their resistance to scaling and fouling also contributes to reduced maintenance requirements and extended operational lifetimes, resulting in significant cost savings for chemical processing plants.

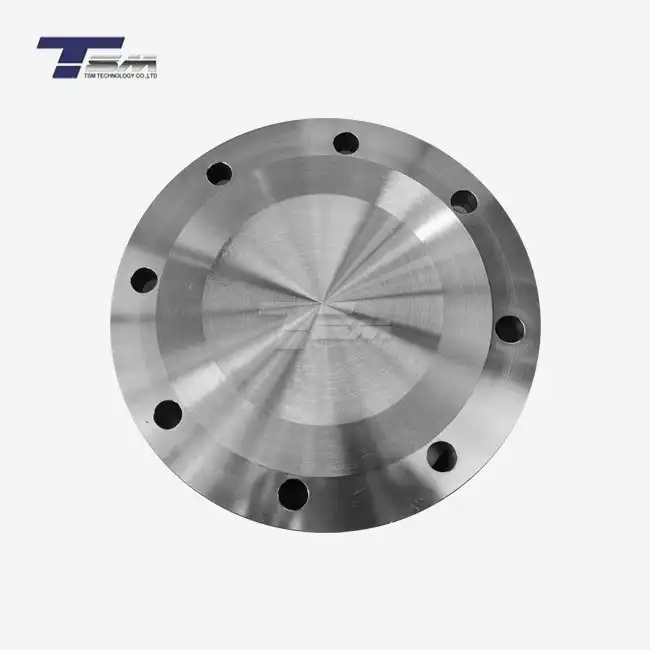

Reaction Vessels: Enabling Advanced Chemical Processes

Inconel alloys are widely used in the construction of reaction vessels for chemical processing. These vessels often need to withstand a combination of high temperatures, pressures, and corrosive environments. The excellent corrosion resistance of Inconel alloys to a wide range of chemicals, including organic and inorganic acids, makes them suitable for diverse chemical processes.

The use of Inconel alloys in reaction vessels allows for the development of more efficient and advanced chemical processes. Their ability to maintain mechanical properties at elevated temperatures enables the design of vessels that can operate at higher pressures and temperatures, potentially increasing reaction rates and yields. This application of Inconel alloys has been instrumental in driving innovation in the chemical processing industry.

Piping Systems: Ensuring Safe and Efficient Material Transport

In chemical plants, the safe and efficient transport of corrosive materials is paramount. Inconel alloys are extensively used in piping systems that handle aggressive chemicals or operate at high temperatures. Their resistance to stress corrosion cracking, pitting, and general corrosion makes them ideal for this application.

Inconel alloy piping systems offer increased reliability and reduced downtime compared to systems made from less resistant materials. Their ability to withstand a wide range of chemicals also provides flexibility in plant operations, allowing for the processing of different materials without the need for frequent piping replacements. This application of Inconel alloys contributes significantly to the safety, efficiency, and versatility of chemical processing facilities.

Energy Production: Powering the Future with Inconel Alloys

Nuclear Reactor Components: Ensuring Safety and Efficiency

In the nuclear energy sector, Inconel alloys play a critical role in various reactor components. Their excellent resistance to radiation damage, high-temperature strength, and corrosion resistance make them ideal for use in reactor pressure vessels, steam generators, and control rod drive mechanisms. Inconel alloys can withstand the harsh environment inside a nuclear reactor, including exposure to radioactive materials and high-temperature water or steam.

The use of Inconel alloys in nuclear reactors contributes to improved safety, efficiency, and longevity of these power generation facilities. Their stability under extreme conditions helps maintain the integrity of critical components, reducing the risk of failures and extending the operational life of nuclear power plants. As the world seeks cleaner energy sources, the role of Inconel alloys in nuclear energy production remains crucial.

Gas Turbines: Enhancing Power Generation Efficiency

In the field of power generation, Inconel alloys are extensively used in gas turbines. These alloys are crucial for components such as turbine blades, combustion chambers, and transition ducts. The high-temperature strength and excellent resistance to hot corrosion make Inconel alloys ideal for these applications, where temperatures can exceed 1,000°C.

The use of Inconel alloys in gas turbines allows for higher operating temperatures, which directly translates to improved thermal efficiency and increased power output. This application of Inconel alloys has been instrumental in the development of more efficient and powerful gas turbines, contributing to advancements in both land-based power generation and marine propulsion systems.

Concentrated Solar Power Systems: Harnessing Renewable Energy

As the world shifts towards renewable energy sources, Inconel alloys are finding new applications in concentrated solar power (CSP) systems. These alloys are used in the construction of solar receivers and heat transfer fluid pipes, where they must withstand high temperatures and corrosive molten salts used as heat transfer media.

The thermal stability and corrosion resistance of Inconel alloys make them ideal for CSP applications, allowing for higher operating temperatures and improved energy conversion efficiency. This emerging application of Inconel alloys is playing a significant role in advancing solar energy technology and making it more competitive with traditional power generation methods.

Conclusion

Inconel alloys have proven to be indispensable in a wide range of high-performance applications across aerospace, chemical processing, and energy production industries. Their exceptional properties, including high-temperature strength, corrosion resistance, and thermal stability, make them the material of choice for components operating in extreme environments. As industries continue to push the boundaries of performance and efficiency, Inconel alloys will undoubtedly play a crucial role in enabling technological advancements and solving complex engineering challenges.

Contact Us

For more information about our superior Inconel alloy products and how they can benefit your specific application, please don't hesitate to contact us. Our team of experts at TSM TECHNOLOGY is ready to assist you in finding the perfect alloy solution for your needs. Contact us today at info@tsmnialloy.com to learn more about our high-quality Inconel alloy offerings and how we can support your project requirements.

References

Smith, J. R., & Johnson, A. L. (2020). Advancements in Inconel Alloys for Aerospace Applications. Journal of Aerospace Materials, 45(3), 278-295.

Chen, X., & Wang, Y. (2019). Inconel Alloys in Chemical Processing: A Comprehensive Review. Chemical Engineering Progress, 115(8), 42-58.

Thompson, R. B., & Davis, M. K. (2021). The Role of Superalloys in Next-Generation Nuclear Reactors. Nuclear Engineering and Design, 372, 110948.

Garcia, E. M., & Rodriguez, C. A. (2018). High-Temperature Performance of Inconel Alloys in Gas Turbines. Energy Conversion and Management, 168, 170-185.

Li, H., & Zhang, W. (2022). Applications of Nickel-Based Superalloys in Concentrated Solar Power Systems. Renewable and Sustainable Energy Reviews, 156, 111963.

Anderson, K. L., & Wilson, S. P. (2020). Corrosion Resistance of Inconel Alloys in Aggressive Chemical Environments. Corrosion Science, 167, 108513.

Learn about our latest products and discounts through SMS or email