- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

Nickel Alloy Screws

3 factories*8 production lines*more than 70+ machines

Supply Ability:100,000 -300,000 PCS

Size :M2.5-M32 or Customized

Length: 1mm-1990 mm or customized

Standards: ASTM, DIN, JIS, BS, GB/T

EN10204 3.1/3.2, Third Party Inspection Report, etc

Delivery time: Usually about 10-25 days(According to your order quantity)

Payment terms: T/T, L/C, Paypal, West Union or as required

MOQ:100PCSProvide Free sample

TSM Technology: Your Trusted Nickel Alloy Screws Manufacturer

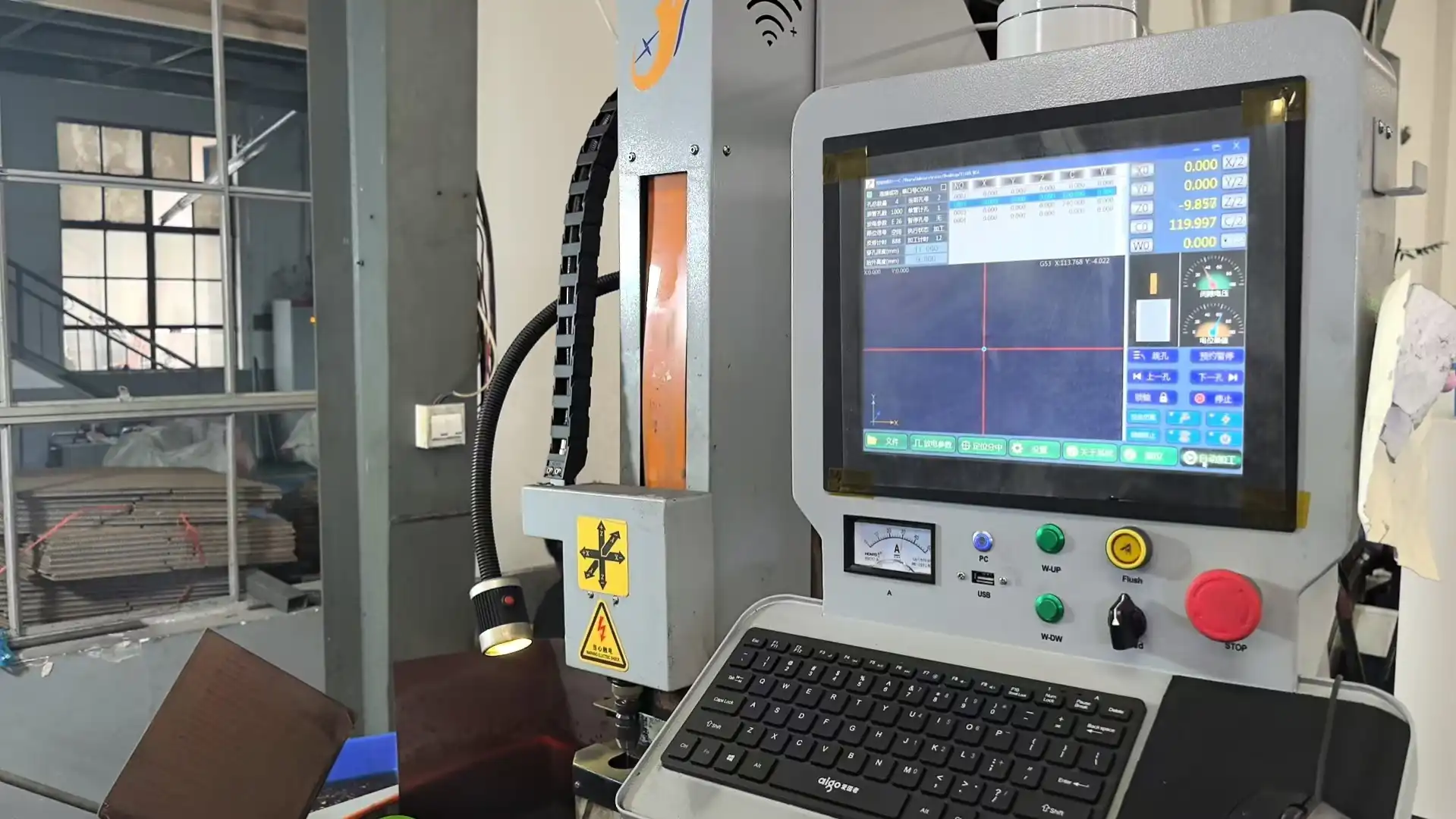

With over 14 years of expertise in precision fastener manufacturing, TSM Technology has established itself as a leading producer of premium Nickel alloy screws. Our 3,200㎡ advanced manufacturing facility houses 100+ precision machines including 5-axis machining centers, CNC lathes, and thread rolling equipment, enabling us to manufacture nickel screws from M1 to M64 with exceptional accuracy. Outlined to stand up to erosion, oxidation, and high temperatures, our screws are the favored choice for experts in the petrochemical, marine, and aviation divisions. Whether for OEM or custom applications, TSM conveys latches that meet your most thorough requests.

What are Nickel Alloy Screws?

Nickel Alloy Screws are specialized fasteners crafted from high-performance nickel-based alloys such as Inconel, Monel, and Hastelloy. These screws excel in extreme conditions where standard fasteners fail, offering:

- Exceptional corrosion resistance

- High-temperature stability

- Superior mechanical strength

- Excellent chemical resistance

Our Nickel Alloy Screws are engineered to maintain their integrity in the harshest environments, ensuring your equipment's reliability and longevity.

Specification

| Feature | Description |

|---|---|

| Size Range | M2.5 - M32 (custom sizes available) |

| Length | 1mm - 1990mm (customizable) |

| Standards | ASTM, DIN, JIS, BS, GB/T |

| Supply Capacity | 100,000 - 300,000 PCS |

| Delivery Time | 10-25 days (order-dependent) |

| MOQ | 100 PCS |

Product Details

Product Standards

We adhere to stringent international standards, including:

- ASTM B164, B165, B166

- EN 10204 3.1/3.2 certification

- ISO 9001:2015 quality management

| Nickel Alloy Type | Common Designations | ASTM Standards | DIN Standards | Key Characteristics | Typical Fastener Applications |

|---|---|---|---|---|---|

| Alloy 200 | UNS N02200 | ASTM B160 (Rod) | DIN 17740 | Commercially pure nickel, excellent corrosion resistance | Chemical processing, food industry |

| Alloy 201 | UNS N02201 | ASTM B161 (Tube) | DIN 17740 | Low-carbon version of Alloy 200 | High-temperature fasteners |

| Monel 400 | UNS N04400 | ASTM B164 (Bar) | DIN 17743 | Ni-Cu alloy, seawater resistant | Marine hardware, offshore platforms |

| Monel K500 | UNS N05500 | ASTM B865 (Forgings) | DIN 17744 | Age-hardenable, high-strength | High-performance marine fasteners |

| Inconel 600 | UNS N06600 | ASTM B166 (Bar) | DIN 17750 | Ni-Cr-Fe alloy, heat resistant | Aerospace, furnace components |

| Inconel 625 | UNS N06625 | ASTM B446 (Bar) | DIN 17752 | Ni-Cr-Mo, superior strength | Nuclear, chemical processing |

| Inconel 718 | UNS N07718 | ASTM B637 (Bar) | DIN 17754 | Precipitation-hardenable | Jet engine fasteners |

| Hastelloy C276 | UNS N10276 | ASTM B574 (Bar) | DIN 17753 | Excellent chemical resistance | Chemical/petrochemical plants |

Material Characteristics

Our Nickel Alloy Screws boast

Low thermal expansion

Maintains dimensional stability in high-temperature cycling

01

Non-magnetic properties

Ideal for sensitive electronic and medical applications

02

Oxidation resistance

Withstands temperatures up to 1000°C (1832°F) in corrosive atmospheres

03

Excellent fatigue strength

Superior durability in high-vibration applications

04

Key Applications

Nickel Alloy Screw are crucial in:

- Oil & Gas: Platform hardware, subsea components

- Chemical Processing: Reactor vessels, piping systems

- Nuclear: Reactor internals, fuel assembly parts

- Aerospace: Engine mounts, turbine components

- Marine: Propulsion systems, desalination plants

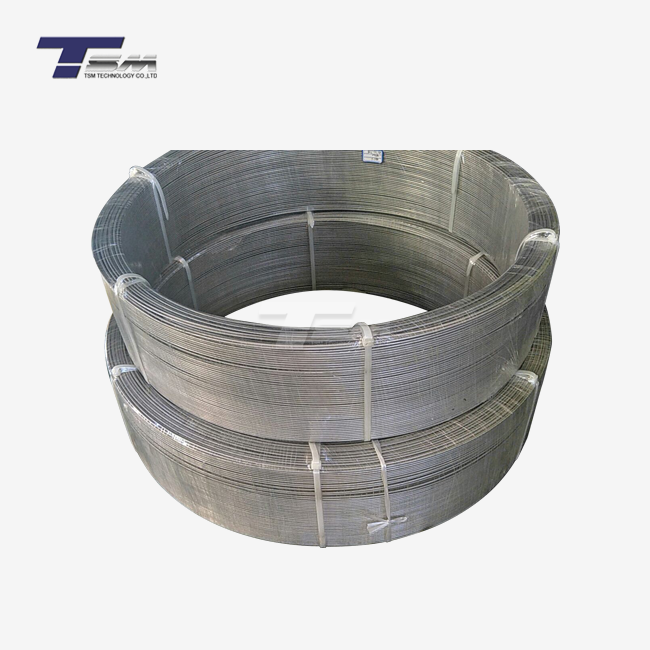

Production Process

Processing Equipment

Our Service

We are looking for partners around the world to expand our business.

Customized production

size, shape, process customization on demand, support for reverse development of drawings/samples.

Specification supply

thread M2.5-M64, pressure level Class 50 to Class 2500.

Full product category coverage

hexagonal bolts, nuts, studs, U-bolts, etc., support non-standard customization

Fast proofing service

Provide samples in 5-7 days to accelerate the project verification cycle

Heat treatment optimization

Solution treatment, annealing, aging treatment, and precise matching of performance requirements.

Industry Certifications

EN10204 3.1/3.2, Third-Party Inspection Reports available.

Packaging and shipment

Why Choose TSM Technology?

- 14+ years of industry expertise

- State-of-the-art manufacturing (3 factories, 8 production lines)

- Strict quality control measures

- Customization capabilities

- Competitive pricing for bulk orders

- Global shipping and support

Certificates

- ISO 9001:2015

- EN 10204 3.1/3.2

- Third-party inspection reports are available

FAQ

Q: What's the minimum order quantity?

A: Our MOQ is 100 PCS, with flexibility for larger orders.

Q: Can you provide custom sizes?

A: Yes, we specialize in customized solutions to meet your specific requirements.

Q: What's your typical lead time?

A: Generally 10-25 days, depending on order quantity and specifications.

Contact Us

Ready to elevate your project with TSM Technology's premium Nickel Alloy Screws? Our team is here to assist you with expert advice and tailored solutions.

Email: info@tsmnialloy.com

Learn about our latest products and discounts through SMS or email

Learn about our latest products and discounts through SMS or email