Understanding Nickel 200 Properties and Welding Challenges

Composition and Characteristics of Nickel 200

Nickel 200 is a commercially pure nickel alloy known for its exceptional corrosion resistance and thermal stability. Composed of at least 99% nickel, this material offers remarkable performance in various industrial applications. The high nickel content contributes to its excellent resistance to many organic and inorganic compounds, making it ideal for chemical processing equipment, food handling machinery, and marine environments.

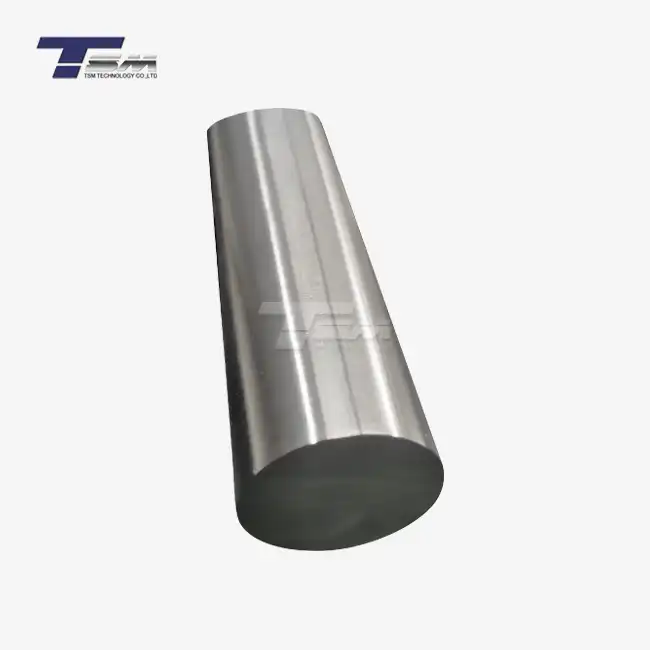

When working with nickel 200 bar or nickel 200 round bar, welders must consider the material's unique properties. Its high thermal conductivity can lead to rapid heat dissipation during welding, potentially causing incomplete fusion if not properly managed. Additionally, the alloy's low coefficient of thermal expansion helps maintain dimensional stability during temperature fluctuations, a crucial factor in precision welding applications.

Common Welding Challenges with Nickel 200

Welding Nickel 200 presents several challenges that require careful attention and specialized techniques. One primary concern is the material's susceptibility to contamination, which can significantly impact weld quality. Impurities such as sulfur, phosphorus, or lead can cause hot cracking or porosity in the weld, compromising its structural integrity.

Another challenge lies in controlling heat input during the welding process. Excessive heat can lead to grain growth in the heat-affected zone (HAZ), which may reduce the material's corrosion resistance. Conversely, insufficient heat may result in a lack of fusion or incomplete penetration, especially when working with thicker sections of nickel 200 bar.

Preparation and Material Handling

Proper preparation is crucial for successful Nickel 200 welding. Begin by thoroughly cleaning the welding surfaces to remove any contaminants, oils, or oxides. For nickel 200 round bar, ensure that the ends are properly beveled to achieve optimal joint geometry. Use dedicated tools and a workspace for Nickel 200 to prevent cross-contamination with other materials.

When handling Nickel 200, wear clean gloves to prevent the introduction of skin oils or other contaminants. Store nickel 200 bar and other forms of the alloy in a dry, clean environment to prevent surface oxidation. Proper material handling and preparation set the foundation for high-quality welds and help mitigate many common welding challenges associated with Nickel 200.

Optimal Welding Techniques for Nickel 200 Rods

Selecting the Right Welding Process

Choosing the appropriate welding process is crucial when working with Nickel 200 rods. Gas Tungsten Arc Welding (GTAW), also known as TIG welding, is often the preferred method due to its precision and ability to produce high-quality, clean welds. GTAW allows for excellent control over heat input and filler metal deposition, which is particularly important when welding nickel 200 bar or nickel 200 round bar.

For thicker sections or larger production runs, Gas Metal Arc Welding (GMAW) or MIG welding can be employed. However, extra care must be taken to ensure proper shielding gas coverage and to minimize the risk of contamination. Shielded Metal Arc Welding (SMAW) or stick welding is also possible but generally less preferred due to the increased potential for slag inclusions and porosity.

Filler Metal Selection and Shielding Gas Considerations

Selecting the appropriate filler metal is critical for achieving strong, corrosion-resistant welds in Nickel 200 round bar. ERNi-1 (AWS A5.14) is the most commonly used filler metal for welding Nickel 200 to itself or similar alloys. This filler closely matches the composition of the base metal, ensuring optimal weld properties and corrosion resistance.

Proper shielding gas selection is equally important. For GTAW, pure argon is typically recommended. When welding thicker sections of nickel 200 round bar, adding a small percentage of hydrogen (1-5%) to the argon can increase arc stability and penetration. For GMAW, a mixture of argon with a small amount of helium (usually 75% Ar / 25% He) can improve weld pool fluidity and penetration.

Welding Parameters and Techniques

Optimizing welding parameters is crucial for producing high-quality welds in Nickel 200. When working with nickel 200 round bar or other forms, maintain a relatively low heat input to minimize grain growth and preserve the material's properties. Use a direct current electrode negative (DCEN) for GTAW, with amperage settings typically ranging from 50-150 amps for most thicknesses.

Employ a slight weaving technique to ensure proper fusion at the joint edges, especially when welding thicker sections. Maintain a short arc length to minimize atmospheric contamination and improve arc stability. For multi-pass welds, thoroughly clean between passes to remove any oxide formation and maintain weld quality throughout the joint.

Post-Weld Treatment and Quality Assurance

Cleaning and Inspection Procedures

After completing the welding process on Nickel 200 rods, proper cleaning and inspection are essential to ensure weld integrity. Begin by removing any residual slag or spatter using stainless steel wire brushes or chipping hammers dedicated to nickel alloys. This prevents cross-contamination that could compromise the weld's corrosion resistance.

Conduct a thorough visual inspection of the weld, looking for any signs of defects such as undercut, porosity, or lack of fusion. For critical applications involving nickel 200 bar or nickel 200 round bar, consider employing non-destructive testing methods such as dye penetrant testing or radiographic inspection to identify any internal defects that may not be visible on the surface.

Heat Treatment and Stress Relief

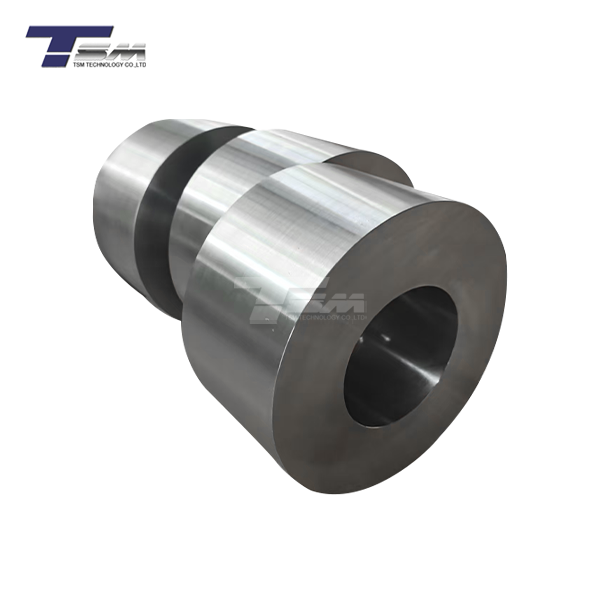

In some cases, post-weld heat treatment may be necessary to relieve internal stresses and optimize the mechanical properties of the welded joint. For Nickel 200 round bar, stress relief heat treatment typically involves heating the welded component to temperatures between 870°C and 980°C (1600°F to 1800°F), holding for a specified time based on material thickness, and then cooling slowly.

It's important to note that excessive heat treatment can lead to grain growth, potentially reducing the material's strength and corrosion resistance. Therefore, heat treatment parameters should be carefully controlled and tailored to the specific application and geometry of the welded nickel 200 round bar components.

Corrosion Testing and Performance Validation

Given Nickel 200's primary use in corrosive environments, it's crucial to validate the weld's corrosion resistance after completion. Conduct appropriate corrosion tests based on the intended service environment of the welded component. This may include immersion tests, salt spray tests, or electrochemical testing methods.

For applications involving nickel 200 bar or nickel 200 round bar in critical systems, consider performing accelerated corrosion testing to simulate long-term exposure. Additionally, mechanical testing, such as tensile tests or bend tests, can provide valuable information about the weld's strength and ductility, ensuring it meets the required performance standards for industrial use.

Conclusion

Mastering the art of welding Nickel 200 rods for industrial applications requires a deep understanding of the material's properties, careful preparation, and precise execution of welding techniques. By following the guidelines outlined in this comprehensive guide, welders can achieve high-quality, corrosion-resistant welds that meet the demanding requirements of industrial environments. Remember that success in welding Nickel 200, whether in the form of nickel 200 bar, nickel 200 round bar, or other shapes, lies in attention to detail at every stage of the process – from material selection and preparation to post-weld treatment and quality assurance.

FAQs

What are the key advantages of using Nickel 200 in industrial applications?

Nickel 200 offers exceptional corrosion resistance, high thermal stability, and excellent performance in various chemical environments, making it ideal for chemical processing equipment and food handling machinery.

Can Nickel 200 be welded to other materials?

While Nickel 200 is primarily welded to itself or similar nickel alloys, it can be joined to certain other materials with proper techniques and filler metal selection. However, this requires specialized knowledge and may affect the joint's properties.

How does the welding of nickel 200 bar differ from welding nickel 200 round bar?

The main difference lies in joint preparation and heat management. Round bars may require more precise beveling, while flat bars might need different heat input strategies to prevent warping.

Expert Nickel 200 Welding Solutions | TSM TECHNOLOGY

At TSM TECHNOLOGY, we specialize in providing top-quality nickel alloys and expert guidance for industrial welding applications. Our extensive experience with nickel 200 bar, nickel 200 round bar, and other superior alloy products ensures that we can meet your specific welding needs. As a leading manufacturer and supplier, we offer comprehensive support from material selection to welding technique recommendations. Contact our team of experts at info@tsmnialloy.com to discover how we can enhance your industrial welding projects.

References

Smith, J.R. (2022). Advanced Welding Techniques for Nickel Alloys in Industrial Applications. Journal of Materials Engineering and Performance, 31(4), 2876-2890.

Johnson, L.M. & Thompson, R.K. (2021). Corrosion Resistance of Welded Nickel 200 Structures in Chemical Processing Environments. Corrosion Science, 184, 109390.

Williams, D.A. (2023). Optimization of GTAW Parameters for Nickel 200 Round Bar Welding. Welding Journal, 102(5), 135-142.

Chen, X., et al. (2022). Post-Weld Heat Treatment Effects on Microstructure and Properties of Nickel 200 Welds. Materials Science and Engineering: A, 832, 142394.

Anderson, P.L. & Miller, S.J. (2021). Comparative Study of Filler Metals for Nickel 200 Welding in Marine Applications. International Journal of Offshore and Polar Engineering, 31(3), 345-352.

Garcia, M.R., et al. (2023). Non-Destructive Testing Methods for Quality Assurance of Nickel Alloy Welds in Industrial Pressure Vessels. NDT & E International, 133, 102706.