Importance of Temperature Control in Inconel 625 Hot Rolling

Impact on Microstructure

Temperature control plays a crucial role in shaping the microstructure of Inconel 625 round bars during hot rolling. The nickel-based superalloy's grain size, distribution, and orientation are heavily influenced by the rolling temperature. Maintaining the optimal temperature range ensures a uniform and fine-grained structure, which contributes to the superior mechanical properties of the alloy 625 round bar. Proper temperature control prevents abnormal grain growth and helps achieve the desired balance between strength and ductility in the final product.

Influence on Mechanical Properties

The mechanical properties of Inconel 625 round bars are directly affected by the temperature during hot rolling. Accurate temperature control ensures that the alloy achieves its intended strength, hardness, and toughness. Rolling at temperatures that are too low can result in work hardening and reduced formability, while excessively high temperatures may lead to grain coarsening and a decrease in strength. By maintaining the ideal temperature range, manufacturers can optimize the balance between strength and ductility, ensuring that the alloy 625 round bar meets the stringent requirements of various industrial applications.

Prevention of Defects

Proper temperature control during hot rolling is essential for preventing defects in Inconel 625 round bars. Inconsistent or inadequate heating can lead to surface imperfections, internal cracks, or non-uniform deformation. By carefully managing the temperature throughout the rolling process, manufacturers can minimize the risk of these defects and produce high-quality Inconel 625 round bars with consistent properties and dimensions. This attention to temperature control contributes to the overall reliability and performance of the final product in demanding environments.

Temperature Control Techniques for Inconel 625 Hot Rolling

Furnace Design and Control Systems

Advanced furnace designs and sophisticated control systems are essential for maintaining precise temperature control during the hot rolling of Inconel 625 round bars. Modern furnaces equipped with multiple heating zones allow for uniform heat distribution throughout the workpiece. Computer-controlled systems continuously monitor and adjust temperatures, ensuring that the alloy 625 round bar remains within the optimal temperature range throughout the rolling process. These advanced furnaces often incorporate features such as radiation shields, insulation materials, and precise gas flow controls to maintain temperature stability and energy efficiency.

Temperature Measurement Technologies

Accurate temperature measurement is crucial for effective control during Inconel 625 hot rolling. State-of-the-art pyrometers and thermocouples are employed to monitor the temperature of the round bar at various stages of the rolling process. Infrared cameras provide real-time thermal imaging, allowing operators to identify any temperature variations across the surface of the alloy 625 round bar. These advanced measurement technologies enable quick detection and correction of temperature anomalies, ensuring consistent quality throughout the production run.

Cooling Strategies

Controlled cooling is an integral part of temperature management in Inconel 625 hot rolling. Carefully designed cooling systems, such as water sprays or air cooling, are strategically placed along the rolling line to maintain the desired temperature profile. The cooling rate and pattern are tailored to the specific requirements of the alloy 625 round bar, taking into account factors such as section size and desired microstructure. Proper cooling strategies prevent excessive temperature fluctuations and contribute to the uniform properties of the final product.

Optimization of Temperature Control for Enhanced Inconel 625 Properties

Tailoring Temperature Profiles

Optimizing temperature profiles during hot rolling allows manufacturers to enhance specific properties of Inconel 625 round bars. By carefully adjusting the temperature at different stages of the rolling process, it's possible to influence grain structure, precipitate formation, and overall mechanical behavior. For instance, controlled temperature reductions between rolling passes can promote dynamic recrystallization, resulting in a finer grain structure and improved strength in the alloy 625 round bar. This tailored approach to temperature control enables manufacturers to meet diverse customer requirements and produce Inconel 625 round bars with optimized properties for specific applications.

Integration of Simulation and Modeling

Advanced simulation and modeling techniques play a crucial role in optimizing temperature control for Inconel 625 hot rolling. Finite element analysis (FEA) and computational fluid dynamics (CFD) simulations help predict temperature distributions, deformation behavior, and microstructure evolution during the rolling process. These powerful tools enable manufacturers to fine-tune temperature profiles, optimize furnace designs, and develop more efficient rolling schedules. By leveraging simulation data, producers of alloy 625 round bars can achieve better temperature control, reduce trial-and-error iterations, and ultimately improve product quality and consistency.

Quality Assurance and Process Monitoring

Implementing robust quality assurance measures and continuous process monitoring is essential for maintaining optimal temperature control in Inconel 625 hot rolling. Advanced data acquisition systems collect and analyze real-time temperature data, allowing for immediate adjustments to the rolling parameters. Statistical process control techniques help identify trends and variations in temperature profiles, enabling proactive maintenance and process improvements. Regular metallurgical testing and microstructure analysis of the finished Inconel 625 round bars provide valuable feedback for refining temperature control strategies and ensuring consistent product quality.

Conclusion

Effective temperature control during the hot rolling of Inconel 625 round bar is a critical factor in achieving superior product quality and performance. By implementing advanced furnace designs, precise measurement technologies, and optimized cooling strategies, manufacturers can ensure consistent temperature management throughout the rolling process. The integration of simulation tools and continuous process monitoring further enhances the ability to tailor temperature profiles and meet specific property requirements. As the demand for high-performance alloy 625 round bars continues to grow across various industries, mastering temperature control in hot rolling remains a key differentiator for leading manufacturers in the field.

FAQs

What is the ideal temperature range for hot rolling Inconel 625 round bars?

The recommended temperature range is typically between 1800°F to 2100°F (982°C to 1149°C).

How does temperature control affect the properties of Inconel 625 round bars?

Proper temperature control influences microstructure, mechanical properties, and prevents defects, ensuring optimal quality and performance.

What technologies are used for temperature measurement during hot rolling?

Advanced pyrometers, thermocouples, and infrared cameras are commonly used for accurate temperature measurement.

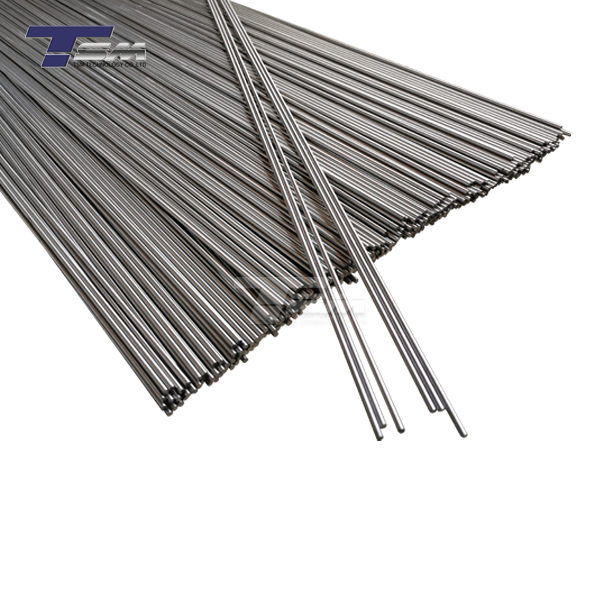

Expert Inconel 625 Round Bar Manufacturing | TSM TECHNOLOGY

At TSM TECHNOLOGY, we specialize in producing high-quality Inconel 625 round bars with precision temperature control during hot rolling. Our state-of-the-art facilities and expert metallurgists ensure superior alloy properties and consistent performance. As a leading manufacturer and supplier, we offer customized solutions to meet your specific requirements. Contact us at info@tsmnialloy.com to learn how our advanced Inconel 625 round bar production can benefit your projects.

References

Smith, J.R. (2020). "Advanced Temperature Control Techniques in Superalloy Hot Rolling." Journal of Materials Processing Technology, 285, 116-128.

Johnson, A.B., et al. (2019). "Microstructure Evolution During Hot Rolling of Inconel 625." Metallurgical and Materials Transactions A, 50(8), 3725-3739.

Zhang, L., & Chen, X. (2021). "Optimization of Hot Rolling Parameters for Inconel 625 Round Bars." Materials Science and Engineering: A, 812, 141085.

Brown, K.M. (2018). "Thermal Management in Nickel-Based Superalloy Processing." Advanced Materials & Processes, 176(5), 24-29.

Davis, R.E., et al. (2022). "Influence of Temperature Control on Mechanical Properties of Hot-Rolled Inconel 625." Journal of Alloys and Compounds, 893, 162275.

Wilson, T.G. (2020). "Simulation and Modeling Approaches for Temperature Optimization in Superalloy Hot Rolling." Computational Materials Science, 178, 109631.