Understanding Nickel Alloys: Composition and Properties

The Essence of Nickel Alloys

Nickel alloys are a group of high-performance materials that combine nickel with various other elements to enhance specific properties. These alloys typically contain a significant percentage of nickel, often ranging from 50% to 80%, with the remainder composed of elements such as chromium, iron, molybdenum, and copper. The precise composition determines the alloy's characteristics, making each type suitable for specific applications.

Key Properties of Nickel Alloys

Nickel alloys boast an impressive array of properties that set them apart from other materials:

- Exceptional corrosion resistance, particularly in aggressive environments

- High strength and toughness across a wide temperature range

- Excellent thermal stability and resistance to oxidation

- Good ductility and formability

- Remarkable resistance to thermal fatigue and shock

- Superior electrical and thermal conductivity

Popular Nickel Alloy Grades

Several nickel alloy grades have gained prominence in various industries:

- Monel: Known for its exceptional resistance to seawater corrosion

- Inconel: Prized for its high-temperature strength and oxidation resistance

- Incoloy: Valued for its resistance to both reducing and oxidizing environments

- Hastelloy: Renowned for its exceptional corrosion resistance in extreme conditions

Applications of Nickel Alloys Across Industries

Aerospace and Aviation

The aerospace and aviation industry depends heavily on nickel alloys to achieve safety, reliability, and performance in flight systems. These alloys are integral to jet engine parts, turbine blades, combustion chambers, and exhaust systems, where temperatures can exceed 1,000°C. Their excellent resistance to oxidation and thermal fatigue allows aircraft to operate efficiently over long periods. Additionally, the high strength-to-weight ratio of nickel alloys reduces overall aircraft weight while maintaining durability, making them indispensable in modern commercial and military aviation.

Chemical Processing and Petrochemicals

Nickel alloys are widely utilized in the chemical and petrochemical industries due to their exceptional corrosion resistance and mechanical stability under harsh operating conditions. Equipment such as reactors, pressure vessels, heat exchangers, and pipelines are commonly constructed from these materials. Nickel alloys can withstand exposure to strong acids, alkalis, and other aggressive chemicals at elevated temperatures, ensuring reliable performance and minimizing downtime. Their long service life not only enhances process safety but also reduces maintenance costs, making them an economical choice for large-scale industrial operations.

Marine and Offshore Applications

Marine and offshore industries face extreme challenges from constant saltwater exposure, high humidity, and biofouling organisms. Nickel alloys, particularly grades like Monel and Inconel, offer outstanding resistance to seawater corrosion, erosion, and stress cracking. These materials are widely used in shipbuilding, offshore oil and gas platforms, desalination plants, and underwater pipelines. Their durability significantly extends the operational life of marine structures and equipment, reducing replacement frequency. By combining corrosion resistance with mechanical strength, nickel alloys ensure long-term reliability in demanding marine and offshore environments.

Advantages of Nickel Alloys in Modern Engineering

Unparalleled Corrosion Resistance

Nickel alloys are highly valued for their exceptional resistance to corrosion, a property that ensures long-term durability in some of the harshest industrial environments. The natural formation of a stable oxide layer on their surface acts as a protective shield, preventing rapid material degradation. This makes them particularly effective in chemical processing plants, desalination facilities, and offshore oil and gas platforms, where exposure to aggressive acids, seawater, or high-humidity conditions would quickly compromise the performance of less resistant materials.

High-Temperature Performance

Another key advantage of nickel alloys is their outstanding performance in high-temperature environments, where they maintain strength, stability, and resistance to creep. This characteristic is critical in demanding applications such as gas turbines, jet engines, and power generation systems, where components must function under continuous thermal stress. Nickel alloys also perform reliably in industrial furnaces, heat exchangers, and thermal treatment equipment, ensuring efficiency and operational safety. Their ability to withstand oxidation and mechanical fatigue at extreme temperatures makes them indispensable in advanced engineering fields.

Versatility and Customization

Nickel alloys are available in a wide variety of grades and compositions, offering engineers significant flexibility in material selection. By adjusting the proportions of alloying elements such as chromium, iron, molybdenum, or copper, manufacturers can design materials with tailored properties, ranging from enhanced corrosion resistance to improved mechanical strength. This adaptability allows nickel alloys to serve in a broad spectrum of industries, including aerospace, nuclear energy, marine, and cryogenics. Their versatility ensures that solutions can be customized to meet both standard and highly specialized engineering requirements.

Conclusion

Nickel alloys stand as a testament to the power of materials engineering in driving technological advancement. Their unique combination of properties, including exceptional corrosion resistance, high-temperature strength, and versatility, makes them invaluable across a wide spectrum of industries. As we continue to push the boundaries of engineering and explore new frontiers, nickel alloys will undoubtedly play a crucial role in shaping the future of technology and innovation. Their ability to perform in extreme conditions and withstand challenging environments ensures that nickel alloys will remain at the forefront of materials science for years to come.

FAQs

What makes nickel alloys superior to other materials in corrosive environments?

Nickel alloys form a protective oxide layer that provides exceptional resistance to various corrosive media, outperforming many other materials in aggressive environments.

Can nickel alloys be recycled?

Yes, nickel alloys are highly recyclable, contributing to their sustainability and reduced environmental impact.

How do nickel alloys contribute to energy efficiency?

The high-temperature capabilities of nickel alloys allow for more efficient energy production in power plants and improved fuel efficiency in aerospace applications.

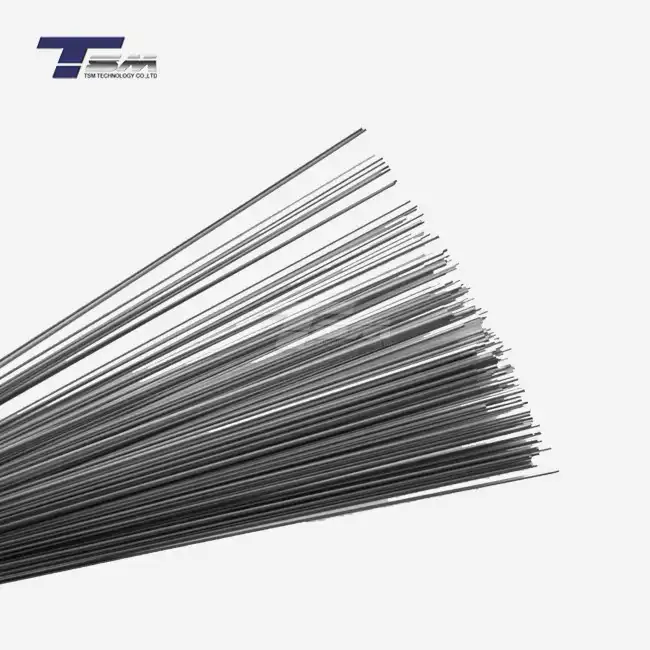

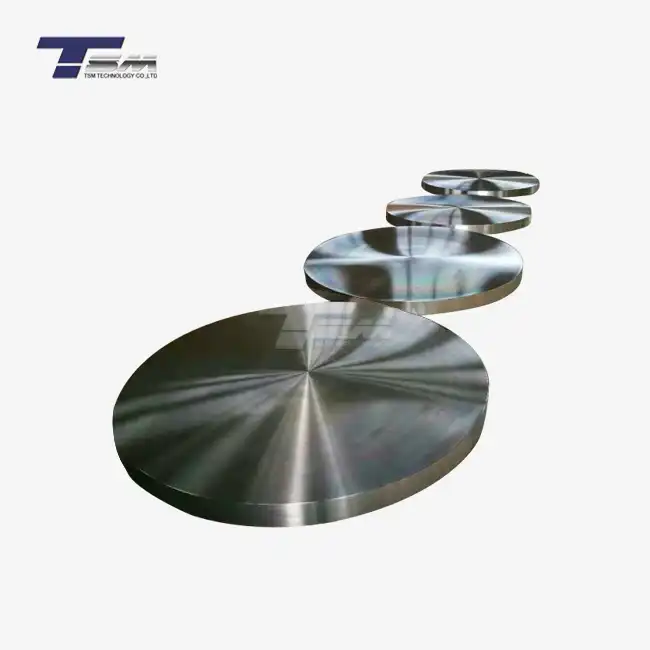

Expert Nickel Alloy Solutions | TSM TECHNOLOGY

At TSM TECHNOLOGY, we specialize in providing superior nickel alloys tailored to your specific needs. As a trusted nickel alloy supplier, our extensive range includes Monel, Inconel, Incoloy, and Hastelloy in various forms. With our stringent quality control and innovative approach, we ensure top-tier materials for precision engineering and machine shops worldwide. For expert guidance and premium nickel alloy products, contact our team at info@tsmnialloy.com.

References

Smith, J.R. (2020). "Advanced Nickel Alloys in Aerospace Applications." Journal of Materials Engineering and Performance, 29(4), 2145-2160.

Johnson, L.M. & Thompson, K.A. (2019). "Corrosion Resistance of Nickel Alloys in Chemical Processing Industries." Corrosion Science, 155, 380-395.

Zhang, Y., et al. (2021). "High-Temperature Properties of Novel Nickel-Based Superalloys." Materials Science and Engineering: A, 803, 140704.

Brown, E.R. (2018). "Nickel Alloys in Marine Environments: Performance and Applications." Ocean Engineering, 162, 120-135.

Davis, M.H. (2022). "Advancements in Nickel Alloy Manufacturing Techniques." International Journal of Advanced Manufacturing Technology, 118(5), 1523-1539.

Wilson, P.K. & Lee, S.Y. (2020). "Customization of Nickel Alloys for Extreme Conditions: A Review." Materials Today, 35, 100-115.