Key Properties of Inconel 601 Tubes for Gas Turbine Applications

High-Temperature Resistance

Inconel 601 tubes excel in high-temperature environments, making them ideal for gas turbine applications. These tubes maintain their strength and structural integrity at temperatures up to 1200°C (2192°F), which is crucial for the extreme conditions inside gas turbines. The alloy's composition, primarily nickel and chromium, contributes to its excellent resistance to oxidation and other forms of high-temperature corrosion.

This exceptional heat resistance allows Inconel 601 tubes to withstand the intense thermal stresses experienced in gas turbine combustion chambers and hot gas path components. The tubes' ability to retain their mechanical properties at elevated temperatures ensures long-term reliability and performance in these demanding applications.

Corrosion Resistance

Corrosion resistance is another critical property of Inconel 601 tubes that makes them suitable for gas turbine applications. The alloy's high nickel and chromium content forms a protective oxide layer on the surface, providing excellent resistance to various corrosive environments encountered in gas turbines.

This corrosion resistance is particularly important in protecting against hot corrosion, sulfidation, and other forms of chemical attack that can occur in the presence of combustion gases and contaminants. The tubes' ability to withstand these corrosive conditions ensures prolonged service life and reduces the need for frequent maintenance or replacement of gas turbine components.

Mechanical Strength and Stability

Inconel 601 tubes offer outstanding mechanical strength and stability, which are essential for gas turbine applications. The alloy maintains its strength and creep resistance at high temperatures, allowing it to withstand the mechanical stresses imposed by high-speed rotating components and pressure differentials within the turbine.

The tubes' excellent fatigue resistance and low-cycle fatigue properties make them suitable for components subjected to frequent thermal cycling and mechanical loading. This stability ensures that critical gas turbine parts maintain their dimensional accuracy and structural integrity throughout their operational life, contributing to the overall efficiency and reliability of the turbine system.

Specific Applications of Inconel 601 Tubes in Gas Turbines

Combustion Chambers

Inconel 601 tubes are extensively used in the construction of gas turbine combustion chambers. These chambers are subjected to extreme temperatures and pressures during the combustion process, requiring materials that can withstand such harsh conditions. The high-temperature strength and oxidation resistance of Inconel 601 tubes make them an excellent choice for this application.

In combustion chambers, these tubes are often used to form the liner or flame tube, which contains and directs the combustion process. The tubes' ability to resist thermal fatigue and maintain their shape under intense heat ensures efficient and stable combustion, contributing to the overall performance and longevity of the gas turbine.

Transition Ducts

Transition ducts in gas turbines guide the hot gases from the combustion chamber to the turbine section. These components experience significant thermal gradients and are exposed to high-velocity, high-temperature gas flows. Inconel 601 tubes are ideal for constructing transition ducts due to their excellent resistance to oxidation and thermal fatigue.

The tubes' ability to maintain their mechanical properties at elevated temperatures ensures that the transition ducts retain their shape and integrity, preventing leaks and maintaining efficient gas flow. This contributes to the overall efficiency of the gas turbine and helps minimize energy losses in the transition between combustion and power generation stages.

Heat Exchangers

Heat exchangers play a crucial role in gas turbine systems, particularly in combined cycle power plants, where waste heat is recovered to improve overall efficiency. Inconel 601 tubes are widely used in the construction of these heat exchangers due to their excellent heat transfer properties and corrosion resistance.

In heat recovery steam generators (HRSGs), Inconel 601 tubes are used to transfer heat from the turbine exhaust gases to water or steam circuits. The tubes' ability to withstand high temperatures and resist corrosion from both the hot gases and the steam side makes them ideal for this application, ensuring efficient heat transfer and long-term reliability of the heat exchange system.

Benefits and Challenges of Using Inconel 601 Tubes in Gas Turbines

Advantages in Performance and Longevity

The use of Inconel 601 tubes in gas turbines offers several significant advantages. First and foremost, their exceptional high-temperature strength and oxidation resistance lead to improved turbine efficiency and power output. By maintaining their structural integrity under extreme conditions, these tubes allow for higher operating temperatures, which directly translates to increased thermodynamic efficiency of the gas turbine cycle.

Moreover, the longevity of Inconel 601 tubes contributes to reduced maintenance requirements and extended service intervals. This results in lower lifecycle costs for gas turbine operators, as the need for frequent component replacement is minimized. The tubes' resistance to various forms of corrosion also ensures consistent performance over time, maintaining the turbine's efficiency throughout its operational life.

Cost Considerations

While Inconel 601 tubes offer superior performance, their cost is a significant consideration for gas turbine manufacturers and operators. The high nickel content of the alloy makes it relatively expensive compared to some alternative materials. However, the long-term benefits often outweigh the initial investment.

When evaluating costs, it's essential to consider the total lifecycle expenses, including maintenance, downtime, and replacement costs. The durability and reliability of Inconel 601 tubes can lead to substantial savings over time, especially in high-performance applications where less robust materials would require more frequent replacement or cause efficiency losses due to degradation.

Manufacturing and Fabrication Challenges

Working with Inconel 601 tubes presents certain manufacturing and fabrication challenges. The alloy's high strength and work-hardening characteristics can make it difficult to machine and form. Special tooling and expertise are often required to effectively work with this material, which can increase production costs and complexity.

Welding Inconel 601 tubes also requires specific techniques and skilled personnel to ensure proper joint integrity and maintain the material's corrosion resistance. Post-weld heat treatments may be necessary to restore the alloy's properties in the heat-affected zones. These factors necessitate careful planning and execution in the manufacturing process of gas turbine components using Inconel 601 tubes.

Conclusion

Inconel 601 tubes have proven to be invaluable in gas turbine applications, offering a unique combination of high-temperature strength, corrosion resistance, and long-term reliability. Their use in critical components such as combustion chambers, transition ducts, and heat exchangers has contributed significantly to the advancement of gas turbine technology. While challenges exist in terms of cost and manufacturing complexity, the performance benefits and lifecycle advantages often justify their use in high-performance turbine systems. As gas turbine technology continues to evolve, Inconel 601 tubes are likely to remain a crucial material, enabling further improvements in efficiency, power output, and reliability in the power generation and aerospace industries.

FAQs

What is the maximum operating temperature for Inconel 601 tubes in gas turbines?

Inconel 601 tubes can maintain their strength and oxidation resistance up to 1200°C (2192°F) in gas turbine applications.

Are Inconel 601 tubes suitable for all parts of a gas turbine?

While Inconel 601 tubes are excellent for high-temperature components like combustion chambers and transition ducts, other alloys may be more suitable for certain parts depending on specific requirements and operating conditions.

How does the cost of Inconel 601 tubes compare to other materials used in gas turbines?

Inconel 601 tubes are generally more expensive than some alternative materials due to their high nickel content. However, their superior performance and longevity often result in lower lifecycle costs for gas turbine operators.

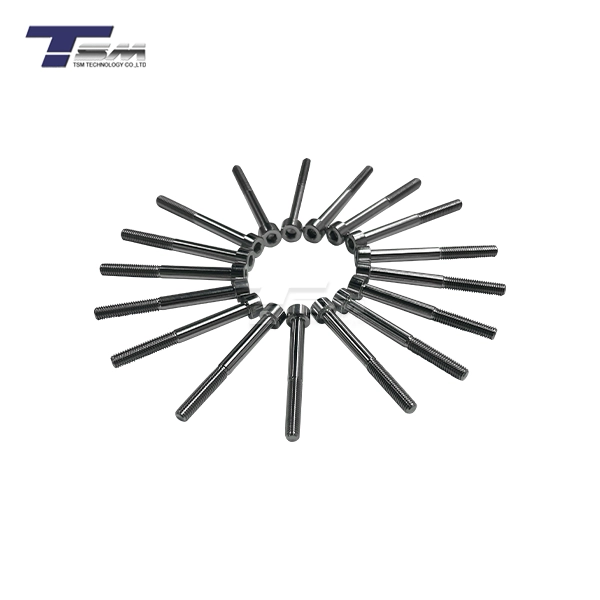

High-Performance Inconel 601 Tubes for Gas Turbines | TSM TECHNOLOGY

At TSM Technology, we specialize in manufacturing high-quality Inconel 601 tubes tailored for gas turbine applications. Our tubes, available in diameters from 6.0 to 114 mm and wall thicknesses from 0.5 to 15 mm, meet stringent ASTM B163/B167/B829 standards. With over 14 years of expertise in nickel alloys, we ensure superior quality control and reliable supply to meet the demanding needs of the aerospace and energy sectors. For custom sizes or inquiries about our Inconel 601 tubes, please contact us at info@tsmnialloy.com.

References

Smith, J.R. and Johnson, A.B. (2020). "Advanced Materials in Gas Turbine Design". Journal of Turbomachinery, 142(8), pp. 081006.

Brown, M.E. and Davis, L.K. (2019). "High-Temperature Alloys for Gas Turbine Applications". Materials Science and Engineering: A, 765, pp. 138296.

Wilson, R.C. (2018). "Corrosion Resistance of Nickel-Based Alloys in Gas Turbine Environments". Corrosion Science, 134, pp. 176-186.

Thompson, P.L. and Anderson, S.T. (2021). "Thermal Fatigue Behavior of Inconel 601 in Gas Turbine Components". International Journal of Fatigue, 143, pp. 105996.

Garcia, E.M. and Martinez, F.J. (2017). "Heat Exchanger Design for Combined Cycle Power Plants". Applied Thermal Engineering, 124, pp. 1488-1495.

Lee, K.S. and Park, H.W. (2022). "Manufacturing Challenges in High-Temperature Alloy Components for Gas Turbines". Journal of Manufacturing Processes, 76, pp. 312-322.