Understanding Incoloy 825 Round Bars and Their Properties

Composition and Characteristics of Incoloy 825

Incoloy 825 is a nickel-iron-chromium alloy with added molybdenum, copper, and titanium. This unique composition gives the material exceptional resistance to corrosion in various aggressive environments. The alloy's high nickel content provides excellent resistance to chloride stress corrosion cracking and pitting, while the presence of molybdenum enhances its resistance to reducing environments.

Applications of Incoloy 825 Round Bars

Due to their superior mechanical and chemical properties, Incoloy 825 round bars find extensive use in demanding industries. They are commonly employed in chemical processing equipment, oil and gas extraction tools, pollution control systems, and nuclear fuel reprocessing plants. The material's ability to maintain its strength and corrosion resistance at elevated temperatures makes it ideal for heat exchangers and process piping in aggressive media.

Importance of Mechanical Strength Testing

Mechanical strength testing is crucial for ensuring the reliability and safety of components made from Incoloy 825 round bars. These tests verify that the material meets specified standards and can withstand the intended operating conditions. Accurate strength data is essential for engineers to design equipment that can operate safely under high stress and in corrosive environments, ultimately preventing failures and extending the lifespan of critical industrial components.

Key Methods for Testing Mechanical Strength of Incoloy 825 Round Bars

Tensile Testing Procedures

Tensile testing is a fundamental method for assessing the mechanical strength of Incoloy 825 round bars. This test involves applying a controlled tensile force to a standardized specimen until failure occurs. The process measures several key properties:

- Ultimate Tensile Strength (UTS): The maximum stress the material can withstand before fracturing.

- Yield Strength: The stress at which the material begins to deform plastically.

- Elongation: The extent to which the material stretches before breaking, indicating ductility.

Tensile tests for Incoloy 825 round bars are typically conducted according to ASTM E8 standards, using specialized testing machines that provide precise force and displacement measurements.

Hardness Testing Techniques

Hardness testing evaluates the resistance of Incoloy 825 round bars to localized plastic deformation. Common methods include:

- Brinell Hardness Test: Uses a hardened steel ball to create an indentation on the material surface.

- Rockwell Hardness Test: Employs either a diamond cone or hardened steel ball indenter, depending on the scale used.

- Vickers Hardness Test: Utilizes a diamond pyramid indenter, suitable for measuring the hardness of small parts or thin sections.

These tests provide valuable information about the material's wear resistance and strength, which are crucial for applications involving abrasive or high-pressure environments.

Impact Testing Methods

Impact testing assesses the toughness of Incoloy 825 round bars, measuring their ability to absorb energy during sudden, high-speed loading. The most common method is the Charpy V-notch test, conducted according to ASTM E23 standards. In this test, a notched specimen is struck by a pendulum hammer, and the energy absorbed during fracture is measured. This data is particularly important for applications where the material may be subjected to sudden loads or temperature changes, helping engineers predict its behavior under dynamic stress conditions.

Interpreting Test Results and Ensuring Quality Control

Analyzing Mechanical Strength Data

Interpreting the results of mechanical strength tests requires a thorough understanding of material science and engineering principles. Key considerations include:

- Comparing test results to established standards and specifications for Incoloy 825.

- Evaluating the consistency of results across multiple samples to ensure uniformity.

- Identifying any anomalies or deviations that may indicate material defects or processing issues.

Engineers and quality control specialists use this data to make informed decisions about the suitability of Incoloy 825 round bars for specific applications, ensuring that the material meets or exceeds the required performance criteria.

Quality Control Measures in Production

Maintaining consistent quality in the production of Incoloy 825 round bars involves implementing rigorous quality control measures throughout the manufacturing process. These measures typically include:

- Regular testing of raw materials to ensure proper composition.

- Monitoring and controlling processing parameters such as temperature, pressure, and cooling rates during production.

- Conducting non-destructive testing (NDT) methods like ultrasonic testing or magnetic particle inspection to detect internal defects.

- Performing periodic mechanical strength tests on samples from each production batch.

By adhering to strict quality control protocols, manufacturers can ensure that every Incoloy 825 round bar meets the highest standards of mechanical strength and reliability.

Certification and Documentation

Proper certification and documentation of test results are crucial for traceability and quality assurance. This typically involves:

- Issuing material test reports (MTRs) that detail the chemical composition and mechanical properties of each batch.

- Maintaining comprehensive records of all testing procedures and results.

- Obtaining third-party certifications to validate the testing processes and results.

These documents provide customers with assurance of the material's quality and help manufacturers demonstrate compliance with industry standards and regulatory requirements.

Conclusion

Testing the mechanical strength of Incoloy 825 round bars is a critical process that ensures the material's suitability for demanding industrial applications. Through a combination of tensile, hardness, and impact testing, manufacturers can comprehensively evaluate the material's performance characteristics. Rigorous quality control measures and accurate interpretation of test results are essential for maintaining the high standards expected of this versatile alloy. By understanding and implementing these testing methodologies, engineers and manufacturers can confidently utilize Incoloy 825 round bars in critical components, knowing that they will deliver reliable performance in even the most challenging environments.

FAQs

What are the key mechanical properties tested for Incoloy 825 round bars?

The main properties tested include tensile strength, yield strength, elongation, hardness, and impact resistance.

How often should Incoloy 825 round bars be tested during production?

Testing frequency depends on production volume and specific industry standards, but typically, samples from each batch or heat should be tested.

Can mechanical strength testing predict the corrosion resistance of Incoloy 825?

While mechanical testing doesn't directly measure corrosion resistance, it ensures the material meets specifications that correlate with its overall performance, including corrosion resistance.

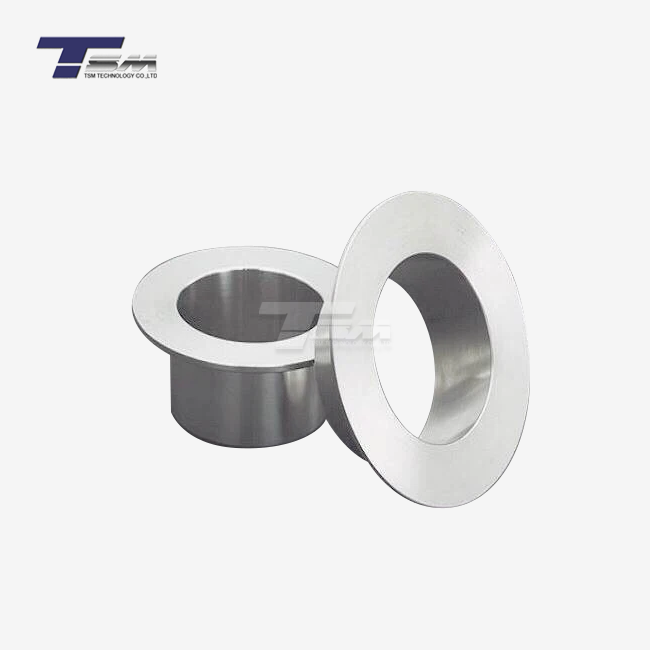

Choose TSM Technology for Premium Incoloy 825 Round Bars

TSM Technology, a leading manufacturer of Incoloy 825 round bars since 2011, offers superior quality products tailored to your specific needs. With our state-of-the-art 3,200㎡ production facility in Shaanxi, China, featuring 3 factories, 8 production lines, and over 100 machines, we ensure consistent, high-quality output. Our Incoloy 825 round bars, available in diameters from 3mm to 400mm, meet ASTM, JIS, AISI, GB, DIN, and EN standards. Trust in our ISO 9001 and AS9100 certified processes for your critical applications. For inquiries or to request a free sample, contact us at info@tsmnialloy.com.

References

ASTM International. (2021). "Standard Test Methods for Tension Testing of Metallic Materials." ASTM E8/E8M-21.

Davis, J.R. (2000). "Nickel, Cobalt, and Their Alloys." ASM International.

Heubner, U. (1998). "Nickel Alloys." CRC Press.

ISO. (2019). "Metallic materials - Tensile testing - Part 1: Method of test at room temperature." ISO 6892-1:2019.

Special Metals Corporation. (2013). "Incoloy alloy 825." Publication Number SMC-077.

Tverberg, J.C. (2001). "Nickel-Base Alloys." Uhlig's Corrosion Handbook, 3rd Edition, John Wiley & Sons.