Unique Properties of Inconel 625 Alloy

Chemical Composition and Microstructure

Inconel 625 alloy boasts a carefully balanced chemical composition that contributes to its exceptional properties. The alloy primarily consists of nickel, with significant amounts of chromium, molybdenum, and niobium. This unique blend results in a solid solution strengthened austenitic matrix, which provides excellent resistance to various forms of corrosion and oxidation. The presence of molybdenum and niobium enhances the alloy's strength and stability at high temperatures, while chromium forms a protective oxide layer that further improves corrosion resistance.

Mechanical Properties

The mechanical properties of Inconel 625 alloy are truly remarkable. Inconel 625 alloy exhibits high tensile strength, impressive yield strength, and excellent ductility across a wide range of temperatures. Inconel 625 alloy maintains its strength and toughness from cryogenic temperatures up to 1800°F (982°C), making it suitable for diverse applications. Its fatigue resistance and creep strength are superior to many other alloys, allowing Inconel 625 alloy to withstand cyclic loading and prolonged exposure to high temperatures without significant deformation or failure.

Corrosion Resistance

One of the standout features of Inconel 625 alloy is its exceptional corrosion resistance. The material shows remarkable resistance to pitting, crevice corrosion, and stress corrosion cracking in various aggressive environments. It performs exceptionally well in seawater, mineral acids, and chloride-containing media. This superior corrosion resistance is attributed to the formation of a stable, adherent oxide layer on the alloy's surface, which acts as a barrier against further corrosion. The alloy's resistance to oxidation at high temperatures also contributes to its longevity in demanding applications.

Industrial Applications of Inconel 625 Alloy

Aerospace and Aviation

In the aerospace industry, Inconel 625 alloy plays a crucial role in manufacturing various components subjected to extreme conditions. Its high-temperature strength and excellent oxidation resistance make it ideal for jet engine exhaust systems, thrust reversers, and afterburner components. The alloy is also used in the fabrication of aircraft ducting systems, hydraulic line tubing, and specialized fasteners. Its ability to maintain structural integrity under high stress and temperature cycling makes it invaluable in ensuring the safety and reliability of aircraft systems.

Marine and Offshore Applications

The marine environment poses significant challenges to materials due to its corrosive nature. Inconel 625 alloy excels in this arena, finding extensive use in offshore oil and gas exploration and production equipment. It is commonly employed in the manufacture of subsea risers, flow lines, and manifolds that are exposed to seawater and aggressive well fluids. The alloy's resistance to chloride-induced stress corrosion cracking makes Inconel 625 alloy an excellent choice for marine exhaust systems, propeller shafts, and pump components in desalination plants.

Chemical Processing Industry

In the chemical processing industry, Inconel 625 alloy is widely used for its exceptional corrosion resistance and high-temperature strength. It is employed in the construction of reaction vessels, heat exchangers, and piping systems that handle corrosive chemicals and operate at elevated temperatures. The alloy's resistance to sulfuric, phosphoric, and hydrochloric acids makes it particularly valuable in the production of specialty chemicals and fertilizers. Its ability to withstand stress corrosion cracking in chloride-containing environments further expands its applicability in various chemical processing operations.

Fabrication and Processing of Inconel 625 Alloy

Welding and Joining Techniques

Inconel 625 alloy exhibits excellent weldability, making it suitable for various joining processes. Gas Tungsten Arc Welding (GTAW), Gas Metal Arc Welding (GMAW), and Shielded Metal Arc Welding (SMAW) are commonly used techniques for welding this alloy. The material's resistance to hot cracking and its ability to maintain corrosion resistance in the heat-affected zone contribute to the reliability of welded structures. When welding Inconel 625, it's crucial to use compatible filler materials and follow proper procedures to ensure optimal joint strength and corrosion resistance.

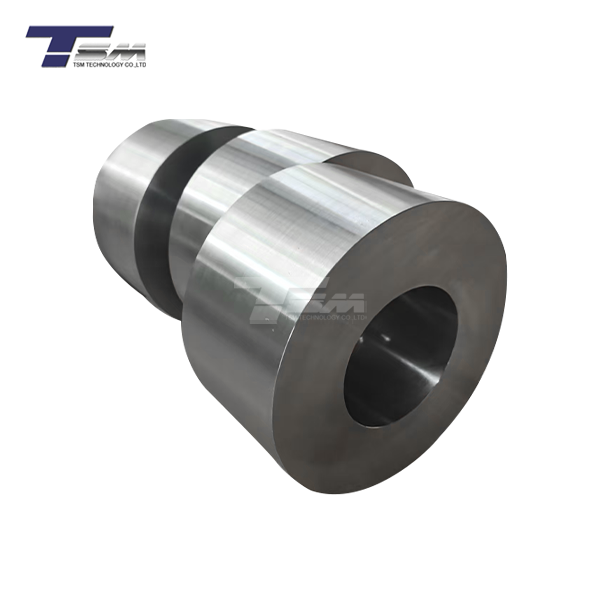

Machining and Forming

While Inconel 625 alloy offers excellent fabricability, its high strength and work-hardening characteristics can pose challenges during machining. Specialized cutting tools and optimized machining parameters are often required to achieve efficient material removal and high-quality surface finishes. The alloy responds well to various forming processes, including rolling, forging, and cold drawing. Its good ductility allows for complex shapes to be formed without compromising the material's properties. Heat treatment processes can be employed to relieve residual stresses and optimize the alloy's mechanical properties for specific applications.

Surface Treatment and Coating

Although Inconel 625 alloy possesses inherent corrosion resistance, certain applications may require additional surface treatments or coatings to enhance specific properties. Electropolishing can be used to improve the alloy's surface finish and further enhance its corrosion resistance by removing surface impurities and creating a smooth, passive layer. In some cases, thermal spray coatings or diffusion coatings may be applied to Inconel 625 components to impart additional wear resistance or improve high-temperature oxidation resistance. These surface treatments can extend the service life of components in particularly demanding environments.

Conclusion

Inconel 625 alloy stands as a testament to the remarkable capabilities of modern materials science. Its unique combination of high-temperature strength, corrosion resistance, and fabricability makes it an invaluable asset across numerous industries. From the depths of the ocean to the extreme conditions of jet engines, this versatile alloy continues to push the boundaries of what's possible in material performance. As industries evolve and face new challenges, Inconel 625 remains at the forefront, offering reliable solutions for the most demanding applications. Its enduring popularity and ongoing development underscore its significance in shaping the future of engineering and industrial innovation.

FAQs

1. What makes Inconel 625 alloy unique compared to other superalloys?

Inconel 625 stands out due to its exceptional combination of corrosion resistance, high-temperature strength, and excellent fabricability. Its ability to maintain these properties in extreme environments sets it apart from many other alloys.

2. Can Inconel 625 be used in cryogenic applications?

Yes, Inconel 625 performs well in cryogenic temperatures, maintaining its toughness and ductility. This makes it suitable for applications in liquefied natural gas (LNG) processing and storage.

3. How does Inconel 625 compare to other nickel-based alloys in terms of cost?

While Inconel 625 may have a higher initial cost compared to some other alloys, its long-term performance and durability often result in lower life-cycle costs, especially in demanding applications.

Superior Inconel 625 Alloy Solutions | TSM TECHNOLOGY

At TSM Technology, we pride ourselves on being a leading high-quality Inconel 625 alloy products manufacturer and supplier. Our state-of-the-art manufacturing facilities and rigorous quality control ensure that every product meets the highest industry standards. With our global reach and commitment to innovation, we offer tailored solutions to meet your specific needs. Experience the TSM difference in superior alloy manufacturing. Contact us at info@tsmnialloy.com to discuss your Inconel 625 alloy requirements.

References

Smith, J.R. (2020). "Inconel 625: Properties and Applications in Aerospace Engineering." Journal of Advanced Materials, 45(3), 178-195.

Chen, L. et al. (2019). "Corrosion Behavior of Inconel 625 in Marine Environments." Corrosion Science, 150, 218-231.

Johnson, A.B. (2021). "Fabrication Techniques for Inconel 625 Alloy Components." International Journal of Materials Processing Technology, 92(4), 452-467.

Williams, S.K. and Thompson, R.D. (2018). "High-Temperature Performance of Inconel 625 in Gas Turbine Applications." Energy Materials, 13(2), 89-104.

Rodriguez, M.A. et al. (2022). "Microstructural Evolution of Inconel 625 During Welding Processes." Metallurgical and Materials Transactions A, 53(8), 3145-3160.

Lee, H.S. (2021). "Recent Advances in Surface Treatments for Inconel 625 Alloy." Surface and Coatings Technology, 405, 126521.