- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

Applications of Nickel 200 and 201 Tube

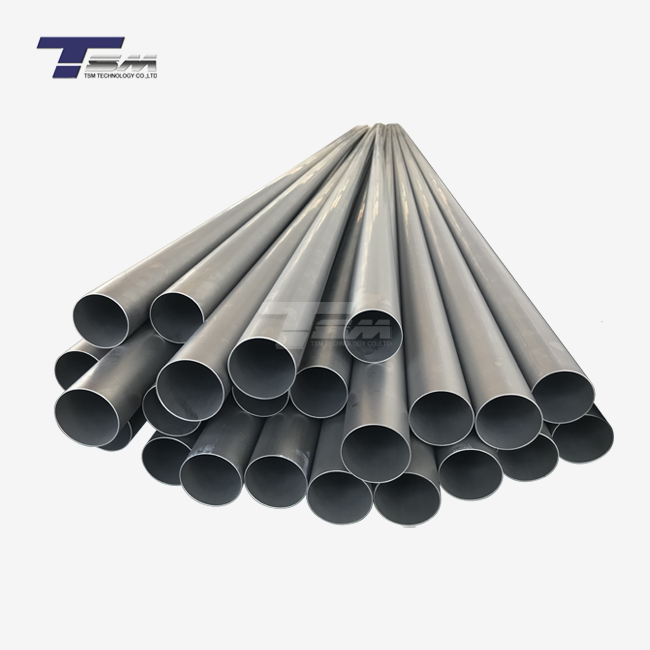

Nickel 200 and 201 are commercially pure wrought nickel alloys, renowned for their exceptional performance in a variety of challenging environments. The primary applications for tubing made from these materials hinge on their outstanding corrosion resistance, particularly to caustic alkalis, and their excellent thermal and electrical conductivity. You will find Nickel 200 tube and Nickel 201 tube extensively used in chemical processing for caustic soda production, food processing where product purity is paramount, and in the electronics industry for components requiring specific magnetic and conductive properties. The key distinction lies in their carbon content, which dictates their optimal service temperature; Nickel 200 is suited for temperatures below 315°C (600°F), while the low-carbon Nickel 201 excels in higher-temperature services.

Unpacking the Core Attributes: Why Choose Pure Nickel Tubing?

Unparalleled Corrosion Resistance

The hallmark of commercially pure nickel is its superb resistance to many corrosive media. This is especially true in reducing environments and, most notably, in the presence of caustic alkalis like sodium hydroxide. At various concentrations and temperatures, these nickel alloys exhibit remarkably low corrosion rates, preserving the integrity of the equipment and the purity of the product. This resistance extends to neutral and alkaline salt solutions, where they show almost no attack. Furthermore, they offer good resistance to acids such as sulfuric and hydrochloric acid under specific reducing conditions and are highly resistant to hydrofluoric acid. This robust defensive characteristic makes tubing from these alloys an indispensable material for handling aggressive chemicals.

The Decisive Factor: Carbon Content and Temperature Limits

While Nickel 200 (UNS N02200) and Nickel 201 (UNS N02201) are nearly identical in many respects, their one critical difference is carbon content. Nickel 200 has a maximum carbon content of 0.15%, whereas Nickel 201 is restricted to a maximum of 0.02%. This seemingly small variation has profound implications for their application. Above approximately 315°C (600°F), the carbon in Nickel 200 can precipitate as graphite, leading to intergranular embrittlement and a loss of ductility. To prevent this, the low-carbon Nickel 201 tube was developed. It is the preferred material for service temperatures exceeding 315°C (600°F), ensuring long-term structural integrity in high-heat processes. Consequently, a Nickel 200 tube is typically specified for applications operating below this temperature threshold.

Exceptional Thermal and Electrical Properties

Beyond their corrosion resistance, Nickel 200 tube and Nickel 201 tube exhibit high thermal and electrical conductivity compared to other nickel-based alloys, stainless steels, and high-temperature alloys. This high thermal conductivity makes them exceptionally efficient for heat transfer applications. Tubing made from these materials is a prime choice for heat exchangers, evaporators, and condenser tubes, particularly in processes involving caustic solutions. Their electrical properties, combined with their magnetostrictive characteristics (the property of materials to change their shape or dimensions during the process of magnetization), make them valuable for specialized electronic components, sensors, and transducers.

Key Industrial Arenas for Nickel 200 and 201 Tubes

The Chemical and Petrochemical Sectors

The most significant use for these nickel alloys is in the chemical industry, particularly in the production and handling of sodium hydroxide (caustic soda). Caustic evaporators, which concentrate the caustic solution, often operate at temperatures where a Nickel 201 tube is the only suitable material to prevent both corrosion and high-temperature embrittlement. The alloy's resistance maintains the purity of the caustic soda, which is vital for its use in industries like rayon and soap manufacturing. These tubes are also used for processing other chemicals like phenol, anhydrous hydrogen chloride, and for the chlorination of hydrocarbons such as benzene. Their durability ensures a long service life, reducing downtime and maintenance costs in these aggressive environments.

Food Processing and Synthetic Fiber Production

In the food processing industry, preventing product contamination is non-negotiable. The purity and excellent corrosion resistance of Nickel 200 make it an ideal material for handling foods and beverages. A Nickel 200 tube is used in systems that process fatty acids, fruit juices, and brines, ensuring that no metallic ions leach into the final product, which could affect taste, color, or safety. Similarly, in the manufacturing of synthetic fibers and certain plastics, process purity is crucial. The stability of nickel tubing in contact with the various chemical intermediates used in these processes helps maintain the quality and consistency of the final synthetic material.

Aerospace and Electronics Components

The applications for pure nickel tubing extend into high-tech fields as well. In aerospace, these materials are used for specific components in rocket motors and other systems that require reliable performance under specific corrosive and thermal conditions. The electronics industry leverages the unique physical properties of these alloys. For instance, the magnetostrictive properties of Nickel 200 are utilized in the manufacturing of transducers and other sonic devices. Its electrical conductivity and resistance to corrosive battery electrolytes make it a suitable material for battery connections, lead wires, and various other electronic parts where reliability and specific electrical characteristics are essential.

Specification and Fabrication Insights for Nickel Alloy Tubing

Understanding Mechanical Properties and Standards

Engineers and designers rely on standardized data to ensure materials meet the demands of an application. Nickel 200 and 201 tubing is typically specified according to standards such as ASTM B161 and ASTM B163, which cover seamless nickel tubes for general service and condenser/heat-exchanger applications, respectively. In the annealed condition, Nickel 200 typically exhibits a tensile strength of around 462 MPa (67,000 psi), while Nickel 201 has a slightly lower tensile strength of about 407 MPa (59,000 psi). These mechanical properties, combined with their excellent ductility and toughness, allow the tubes to be formed and fabricated into complex systems without compromising their structural integrity.

Guidance on Welding and Machinability

Both Nickel 200 tube and Nickel 201 tube are readily weldable by most standard welding processes. However, to maintain the material's purity and corrosion resistance, cleanliness is paramount. It is crucial to thoroughly clean the weld joint and surrounding areas to remove any grease, oil, or other contaminants before welding. Using a filler metal that matches the composition of the base metal is recommended. In terms of machinability, these alloys are known for being somewhat "gummy" and having a high rate of work-hardening. Therefore, using sharp tools, powerful equipment, slow speeds, and ample lubrication is advised to achieve a good surface finish and prevent tool wear.

Partnering with a Specialist Supplier

The performance of a Nickel 200 tube or Nickel 201 tube is directly linked to its quality. Sourcing these materials from a knowledgeable and reputable supplier is critical. As a specialist in superior nickel alloys, TSM Technology Co., Ltd. understands the nuances that differentiate these materials. Our international trading journey began in 2011 in Hong Kong, and over the 14 years since, we have built a reputation for innovation, reliability, and quality. We have developed a very strict quality control and inspection system, where each of our superior alloy products is rigorously checked by professional inspectors. This commitment ensures that every piece of tubing meets the precise chemical and mechanical specifications required for your most critical applications.

Conclusion

The applications of Nickel 200 tube and Nickel 201 tube are a testament to their exceptional combination of properties. Their remarkable corrosion resistance, particularly against caustic chemicals, makes them indispensable in the chemical processing industry. Their purity safeguards quality in food production, while their unique physical characteristics grant them a role in advanced aerospace and electronic systems. The crucial factor in their selection remains the service temperature, with Nickel 200 serving applications below 315°C (600°F) and the low-carbon Nickel 201 providing reliable, long-term performance in more intense heat. As industries continue to push the boundaries of performance and efficiency, the demand for these durable and reliable pure nickel alloys will remain robust, cementing their status as essential engineering materials.

FAQs

What is the main difference between a Nickel 200 tube and a Nickel 201 tube?

The primary difference is the carbon content. Nickel 200 contains up to 0.15% carbon, while Nickel 201 is a low-carbon variant with a maximum of 0.02% carbon. This makes Nickel 201 immune to embrittlement at temperatures above 315°C (600°F), making it the preferred choice for high-temperature caustic service and other elevated-temperature applications.

Can I use Nickel 200 tubing for high-temperature applications?

It is not recommended. While a Nickel 200 tube performs excellently at moderate temperatures, it is susceptible to graphitization and embrittlement when held for extended periods at temperatures above 315°C (600°F). For any application consistently operating above this threshold, a Nickel 201 tube should be specified to ensure safety and long-term mechanical integrity.

Source Your High-Purity Nickel 200 and 201 Tubing with Confidence | TSM TECHNOLOGY

With over 14 years of dedicated experience, TSM TECHNOLOGY has established itself as a leading global manufacturer and factory supplier of superior alloys. We provide high-quality Nickel 200 tube and Nickel 201 tube to precision engineering industries and machine shops worldwide. Our strict quality control systems ensure every product meets the highest standards of reliability and performance. For a partner who understands the critical nature of your applications, contact our expert team for a quote or technical consultation at info@tsmnialloy.com.

References

Davis, J.R., ed. "Nickel, Cobalt, and Their Alloys." ASM Specialty Handbook, 2000.

ASM Handbook, Volume 13A: Corrosion: Fundamentals, Testing, and Protection. ASM International, 2003.

Fontana, M.G. "Corrosion Engineering." 3rd Edition, McGraw-Hill, 1986.

ASTM B163-18, "Standard Specification for Seamless Nickel and Nickel Alloy Condenser and Heat-Exchanger Tubes." ASTM International.

NACE International, "Corrosion Data Survey - Metals Section." 6th Edition, 1985.

International Nickel Company, "Corrosion Resistance of Nickel and Nickel Alloys." Corrosion Engineering Bulletin CEB-2, 1970.

Learn about our latest products and discounts through SMS or email