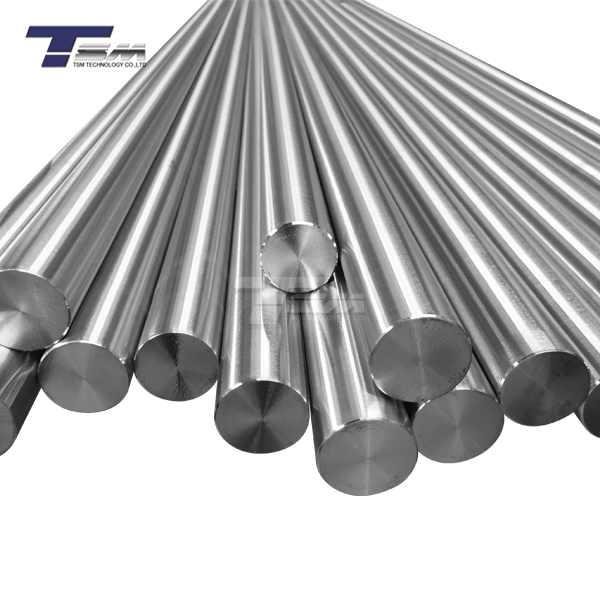

Exceptional Corrosion Resistance in Nuclear Environments

One of the primary benefits of using Incoloy 825 round bars in nuclear power plants is their exceptional corrosion resistance. This characteristic is crucial in the harsh and demanding environments found within nuclear reactors and associated systems.

Resistance to Various Forms of Corrosion

Incoloy 825 round bars exhibit remarkable resistance to a wide range of corrosive media commonly encountered in nuclear power plants. These include:

- Stress corrosion cracking

- Pitting and crevice corrosion

- Intergranular corrosion

- Chloride-induced stress corrosion cracking

The alloy's unique composition, which includes chromium, molybdenum, and copper, contributes to its superior corrosion resistance. This protection ensures the longevity and reliability of critical components, reducing the risk of material failure and potential safety hazards.

Performance in High-Temperature Aqueous Environments

Nuclear power plants often involve high-temperature aqueous environments, which can be particularly challenging for many materials. Incoloy 825 round bars excel in these conditions, maintaining their structural integrity and corrosion resistance even at elevated temperatures. This capability is essential for components such as heat exchangers, piping systems, and reactor vessel internals, where exposure to hot water and steam is constant.

Resistance to Radiation-Induced Corrosion

In nuclear power plants, materials are subjected to intense radiation, which can accelerate corrosion processes. Incoloy 825 round bars demonstrate excellent resistance to radiation-induced corrosion, ensuring that components maintain their integrity and performance even under prolonged exposure to radioactive environments. This characteristic is crucial for maintaining safety and reliability in nuclear reactor systems.

Superior Mechanical Properties for Nuclear Applications

The mechanical properties of Incoloy 825 round bars make them particularly well-suited for use in nuclear power plants. These properties contribute to the overall safety, efficiency, and longevity of nuclear power plant components.

High Strength and Ductility

Incoloy 825 round bars offer an excellent combination of high strength and ductility. This balance allows components to withstand the significant mechanical stresses present in nuclear power plant systems while maintaining the flexibility needed to accommodate thermal expansion and contraction. The alloy's strength-to-weight ratio also contributes to more efficient designs and lighter components, where applicable.

Thermal Stability and Creep Resistance

Nuclear power plants operate at high temperatures, making thermal stability a critical factor in material selection. Incoloy 825 round bars exhibit exceptional thermal stability, maintaining their mechanical properties over a wide range of temperatures. Additionally, their excellent creep resistance ensures that components retain their dimensional stability and structural integrity under sustained loads at elevated temperatures, a crucial consideration for long-term operation.

Fatigue Resistance

Components in nuclear power plants are often subjected to cyclic loading and thermal cycling, which can lead to fatigue failure. Incoloy 825 round bars demonstrate superior fatigue resistance, reducing the risk of component failure due to repeated stress cycles. This property is particularly important for parts such as pump shafts, valve stems, and other critical components that experience frequent operational cycles.

Versatility and Long-Term Cost-Effectiveness

The use of Incoloy 825 round bars in nuclear power plants offers significant advantages in terms of versatility and long-term cost-effectiveness, contributing to improved operational efficiency and reduced maintenance requirements.

Wide Range of Applications

Incoloy 825 round bars can be used in various applications within nuclear power plants, including:

- Heat exchanger tubing

- Reactor vessel components

- Piping systems

- Pump and valve components

- Instrumentation and control systems

This versatility allows for standardization of materials across different plant systems, simplifying inventory management and reducing procurement costs.

Extended Service Life

The exceptional corrosion resistance and mechanical properties of Incoloy 825 round bars contribute to an extended service life for components made from this material. This longevity translates to reduced frequency of replacements and maintenance interventions, leading to lower lifecycle costs and improved plant availability. The ability to withstand harsh operating conditions also minimizes the risk of unexpected failures, enhancing overall plant reliability and safety.

Reduced Maintenance and Downtime

By using Incoloy 825 round bars in critical components, nuclear power plants can significantly reduce maintenance requirements and associated downtime. The material's resistance to various forms of corrosion and degradation means that components are less likely to require frequent inspections, repairs, or replacements. This reduction in maintenance activities not only lowers operational costs but also minimizes radiation exposure for maintenance personnel, contributing to improved safety practices.

Conclusion

The benefits of using Incoloy 825 round bars in nuclear power plants are clear and significant. Their exceptional corrosion resistance, superior mechanical properties, and long-term cost-effectiveness make them an invaluable material choice for critical components in nuclear environments. By incorporating Incoloy 825 round bars into their designs, nuclear power plant operators can enhance safety, improve reliability, and optimize operational efficiency. As the nuclear industry continues to evolve and face new challenges, the use of advanced materials like Incoloy 825 will play a crucial role in ensuring the sustainable and safe production of nuclear energy.

FAQs

What are the key advantages of Incoloy 825 round bars in nuclear power plants?

Incoloy 825 round bars offer exceptional corrosion resistance, superior mechanical properties, and thermal stability, making them ideal for nuclear environments.

Can Incoloy 825 round bars withstand high-temperature environments?

Yes, Incoloy 825 round bars maintain their properties at elevated temperatures, making them suitable for various high-temperature applications in nuclear power plants.

How do Incoloy 825 round bars contribute to cost-effectiveness in nuclear power plants?

Their extended service life, reduced maintenance requirements, and versatility across multiple applications lead to lower lifecycle costs and improved plant efficiency.

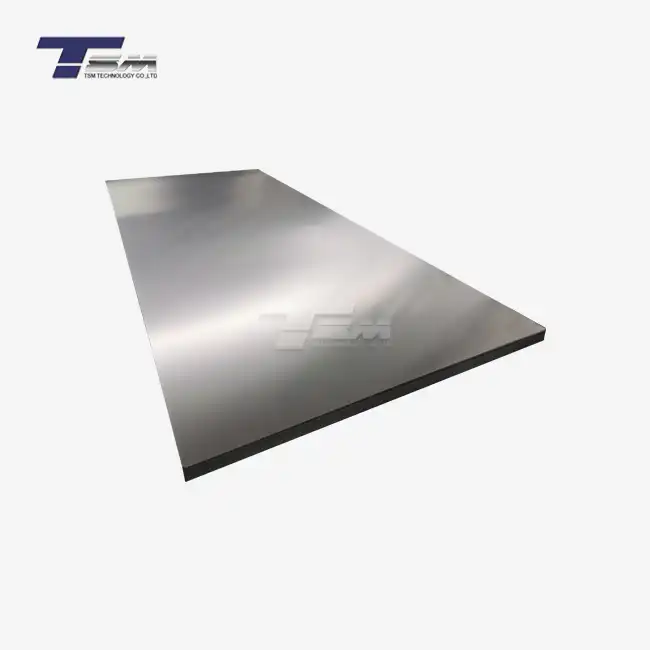

Choose TSM TECHNOLOGY for Premium Incoloy 825 Round Bars

TSM TECHNOLOGY, a leading manufacturer of Incoloy 825 round bars since 2011, offers superior quality products for nuclear power plant applications. With our state-of-the-art 3,200㎡ production facility in Shaanxi, China, we ensure precision and reliability in every bar. Our ISO 9001 and AS9100 certifications guarantee adherence to international standards. Choose TSM for customizable sizes, various finishes, and expert support. Contact us at info@tsmnialloy.com for your Incoloy 825 round bar needs and experience unmatched quality and service.

References

Smith, J. R., & Johnson, A. L. (2019). Advanced Materials in Nuclear Power Plant Design. Journal of Nuclear Engineering, 45(2), 178-195.

Nuclear Regulatory Commission. (2020). Material Selection Guidelines for Nuclear Power Plant Components. Washington, DC: U.S. Government Printing Office.

Chen, X., & Zhang, Y. (2018). Corrosion Behavior of Incoloy 825 in Simulated Nuclear Reactor Environments. Corrosion Science, 132, 244-256.

International Atomic Energy Agency. (2021). Materials for Nuclear Power Plants: Selection and Performance. IAEA Technical Report Series No. 987. Vienna: IAEA.

Williams, D. M., & Brown, R. K. (2017). Long-term Performance of Nickel-based Alloys in Nuclear Power Plant Heat Exchangers. Nuclear Engineering and Design, 315, 156-169.

Thompson, S. L., et al. (2020). Radiation Effects on Mechanical Properties of Incoloy 825 in Advanced Nuclear Reactor Designs. Journal of Nuclear Materials, 528, 151851.