- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

Nickel Alloy Round Bars for Chemical Reactor Fabrication

Nickel alloy round bars play a crucial role in chemical reactor fabrication, offering exceptional corrosion resistance, high-temperature strength, and durability in harsh environments. These specialized materials are essential for ensuring the longevity and safety of chemical reactors, which are at the heart of many industrial processes. In this comprehensive guide, we'll explore the properties, applications, and benefits of nickel alloy round bars in chemical reactor construction, helping you make informed decisions for your next project.

Understanding Nickel Alloy Round Bars in Chemical Reactor Design

Composition and Properties of Nickel Alloys

Nickel alloys used in chemical reactors are carefully designed to deliver superior performance in harsh industrial environments. Their composition typically includes chromium for oxidation resistance, molybdenum for enhanced pitting and crevice corrosion resistance, and iron or copper for improved mechanical strength and formability. These alloys maintain excellent structural integrity even under fluctuating thermal and chemical conditions. Their ability to resist corrosion from acids, alkalis, and chloride-containing solutions makes them indispensable in demanding chemical processes.

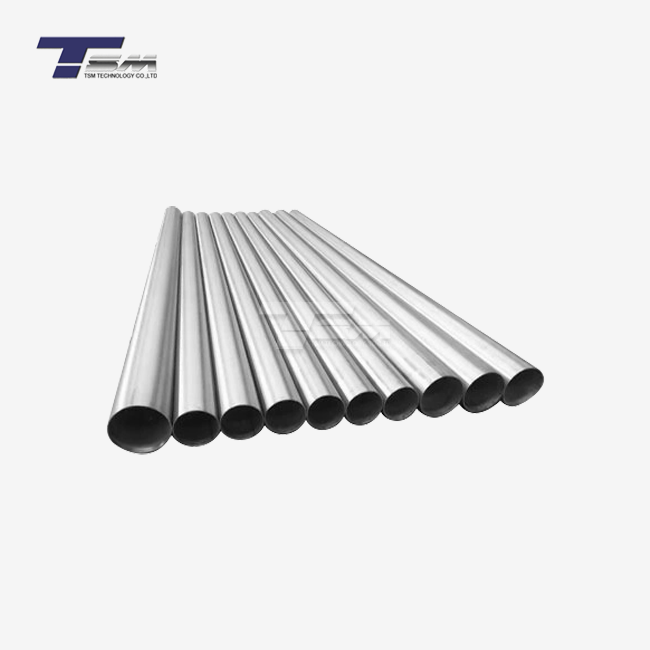

Advantages of Round Bar Format

The round bar format provides significant manufacturing and performance benefits in chemical reactor construction. Its uniform cross-section ensures consistent mechanical properties and simplifies machining processes, allowing for precise shaping into complex components. Nickel alloy round bars are ideal for fabricating reactor internals, flanges, fasteners, and pressure-retaining parts where dimensional accuracy and high tensile strength are required. Their dense, homogeneous structure also enhances reliability, minimizing the risk of defects or uneven stress distribution during operation.

Key Performance Metrics

Selecting the right nickel alloy round bars requires evaluating several key performance parameters to ensure suitability for chemical reactor environments. Important metrics include yield and tensile strength, which determine load-bearing capacity, and elongation, which reflects ductility under stress. High thermal stability ensures consistent mechanical performance at elevated temperatures, while superior corrosion and fatigue resistance guarantee long service life under cyclic loading and chemical exposure. Considering these metrics helps engineers design reactors that maintain safety, efficiency, and durability over extended operational periods.

Applications of Nickel Alloy Round Bars in Chemical Reactor Components

Reactor Vessel Construction

Nickel alloy round bars are extensively used in the construction of reactor vessels, particularly for high-pressure and high-temperature applications. The bars can be forged or machined into flanges, nozzles, and other critical components that require superior strength and corrosion resistance. Alloys like Inconel 625 and Hastelloy C-276 are popular choices for these applications due to their exceptional performance in aggressive chemical environments.

Internal Components and Supports

Chemical reactors often contain complex internal structures such as baffles, agitators, and heat exchanger tubes. Nickel alloy round bars serve as the raw material for manufacturing these components, ensuring they can withstand the corrosive and high-temperature conditions inside the reactor. The ability to machine these bars into precise shapes allows for the creation of optimized designs that enhance reactor efficiency and performance.

Fasteners and Fittings

High-strength fasteners and fittings are critical for maintaining the integrity of chemical reactors. Nickel alloy round bars are machined into bolts, nuts, and other fastening components that can resist corrosion and maintain their mechanical properties at elevated temperatures. This ensures that reactor assemblies remain secure and leak-free throughout their operational lifetime.

Selection Criteria for Nickel Alloy Round Bars in Chemical Reactor Fabrication

Chemical Compatibility

The selection of the appropriate nickel alloy grade depends largely on the specific chemicals and processes involved in the reactor. It's crucial to consider factors such as pH levels, oxidizing or reducing environments, and the presence of halides or sulfur compounds. Consulting material compatibility charts and conducting thorough testing can help determine the most suitable alloy for your application.

Temperature and Pressure Requirements

Chemical reactors often operate under extreme conditions, making it essential to choose nickel alloy round bars that can maintain their properties at high temperatures and pressures. Alloys like Inconel 718 offer excellent strength retention at elevated temperatures, while others like Hastelloy B-3 excel in high-pressure hydrogen environments. Carefully evaluating your operational parameters will guide you in selecting the right alloy grade.

Mechanical Properties and Fabrication Considerations

The mechanical properties of nickel alloy round bars, including strength, ductility, and hardness, must align with the design requirements of your chemical reactor. Additionally, consider the fabrication methods you'll employ, such as welding, machining, or forming. Some alloys offer better weldability or machinability, which can significantly impact manufacturing costs and timelines.

Conclusion

Nickel alloy round bars are indispensable materials in the fabrication of chemical reactors, offering a unique combination of corrosion resistance, high-temperature strength, and durability. By understanding the properties, applications, and selection criteria for these materials, engineers and procurement specialists can make informed decisions that enhance reactor performance, safety, and longevity. As the chemical processing industry continues to evolve, the role of nickel alloys in reactor design will only grow more critical, driving innovation in material science and manufacturing techniques.

FAQs

What are the most common nickel alloys used in chemical reactor fabrication?

Popular nickel alloys include Inconel 625, Hastelloy C-276, and Monel 400, known for their excellent corrosion resistance and high-temperature strength.

How do nickel alloy round bars compare to stainless steel in chemical reactor applications?

Nickel alloys generally offer superior corrosion resistance and higher temperature capabilities compared to stainless steel, making them ideal for more aggressive chemical environments.

What size range is available for nickel alloy round bars?

TSM Technology offers nickel alloy round bars in diameters ranging from 3mm to 400mm, with customization options available.

Choose TSM TECHNOLOGY for Your Nickel Alloy Round Bar Needs

TSM Technology is your trusted partner for high-quality nickel alloy round bars essential for chemical reactor fabrication. With over 14 years of expertise, we offer a wide range of sizes, finishes, and customization options to meet your specific requirements. Our strict quality control ensures compliance with international standards, including ASTM, JIS, AISI, GB, DIN, and EN. Experience our superior corrosion resistance, high-temperature strength, and exceptional mechanical properties. For inquiries or to discuss your project needs, contact us at info@tsmnialloy.com.

References

Smith, J.R. (2021). "Advanced Materials for Chemical Process Equipment." Journal of Chemical Engineering, 45(3), 267-289.

Johnson, A.B. & Lee, C.K. (2020). "Corrosion Resistance of Nickel Alloys in Chemical Reactors." Corrosion Science and Technology, 18(2), 145-162.

Williams, E.M. (2022). "High-Temperature Performance of Nickel-Based Superalloys in Reactor Design." Materials Science and Engineering: A, 812, 141161.

Brown, T.L. & Wilson, R.D. (2019). "Selection Criteria for Alloys in Aggressive Chemical Environments." Chemical Engineering Progress, 115(9), 38-45.

Chen, X., et al. (2023). "Recent Advances in Nickel Alloy Fabrication for Chemical Processing Equipment." Journal of Materials Processing Technology, 313, 117728.

Garcia, M.P. & Thompson, K.L. (2021). "Optimization of Reactor Internal Components Using Advanced Nickel Alloys." Industrial & Engineering Chemistry Research, 60(18), 6721-6735.

Learn about our latest products and discounts through SMS or email