- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

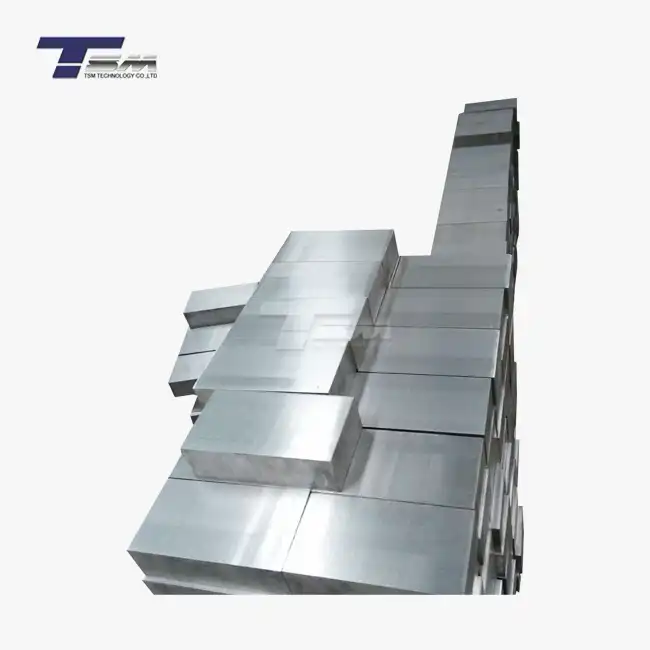

Best Alloys for Pressure Vessels in Chemical Processing

When it comes to selecting the best alloys for pressure vessels in chemical processing, several superior options stand out for their exceptional performance and durability. Nickel-based alloys like Inconel, Hastelloy, and Monel are widely recognized as top choices due to their outstanding corrosion resistance, high-temperature strength, and excellent mechanical properties. These alloys can withstand harsh chemical environments, extreme temperatures, and high pressures, making them ideal for pressure vessels in various chemical processing applications. The selection of the most suitable alloy depends on specific factors such as the nature of the chemicals involved, operating conditions, and desired service life. Understanding the unique properties and advantages of each alloy is crucial for ensuring optimal performance and longevity of pressure vessels in demanding chemical processing environments.

Key Characteristics of Superior Alloys for Pressure Vessels

Corrosion Resistance in Aggressive Chemical Environments

Superior alloys used in pressure vessels for chemical processing exhibit exceptional corrosion resistance. This property is crucial for maintaining the integrity of the vessel and preventing contamination of the chemicals being processed. Nickel-based alloys, in particular, demonstrate remarkable resistance to a wide range of corrosive media, including both reducing and oxidizing environments.

Inconel alloys, for instance, showcase outstanding resistance to oxidation and corrosion, even at elevated temperatures. This makes them particularly suitable for pressure vessels handling aggressive chemicals or operating in high-temperature environments. The chromium content in these alloys forms a protective oxide layer, enhancing their corrosion resistance.

Hastelloy alloys are renowned for their superior corrosion resistance in both oxidizing and reducing environments. They perform exceptionally well in the presence of chlorides, sulfuric acid, and other highly corrosive substances commonly encountered in chemical processing. This makes Hastelloy an excellent choice for pressure vessels in applications involving severe corrosive conditions.

High-Temperature Strength and Stability

Pressure vessels in chemical processing often operate at elevated temperatures, necessitating alloys with excellent high-temperature strength and stability. Superior alloys maintain their mechanical properties even under extreme thermal conditions, ensuring the structural integrity of the vessel.

Inconel alloys, such as Inconel 625 and Inconel 718, exhibit exceptional strength retention at high temperatures. They maintain their mechanical properties up to 1800°F (982°C), making them ideal for pressure vessels in high-temperature chemical processing applications. The addition of elements like molybdenum and niobium contributes to their excellent creep resistance and thermal stability.

Incoloy alloys also demonstrate remarkably high-temperature strength and oxidation resistance. These iron-nickel-chromium alloys are designed to withstand extreme temperatures while maintaining their structural integrity. Incoloy 800H, for example, is widely used in pressure vessels for chemical and petrochemical processing due to its excellent combination of high-temperature strength and corrosion resistance.

Mechanical Properties and Fabricability

Superior alloys for pressure vessels must possess excellent mechanical properties to withstand the high pressures and stresses encountered in chemical processing. Additionally, good fabricability is essential for manufacturing complex pressure vessel designs efficiently.

Monel alloys, such as Monel 400, offer a unique combination of high strength and excellent ductility. This makes them suitable for pressure vessels that require both structural integrity and the ability to withstand cyclic loading. Monel's good weldability and machinability also contribute to its popularity in pressure vessel fabrication.

Hastelloy alloys, while known for their corrosion resistance, also exhibit impressive mechanical properties. They maintain good ductility and toughness even after prolonged exposure to high temperatures. This combination of strength and ductility makes Hastelloy alloys suitable for pressure vessels subject to thermal cycling and mechanical stresses.

Selection Criteria for Pressure Vessel Alloys in Chemical Processing

Chemical Compatibility and Corrosion Resistance

When selecting alloys for pressure vessels in chemical processing, chemical compatibility is paramount. The chosen alloy must demonstrate excellent resistance to the specific chemicals and corrosive media present in the process. This involves considering factors such as pH levels, chloride content, and the presence of oxidizing or reducing agents.

For instance, in processes involving hydrochloric acid, Hastelloy C-276 might be the preferred choice due to its exceptional resistance to this aggressive chemical. On the other hand, for applications involving sulfuric acid at high concentrations and temperatures, alloys like Incoloy 825 or Inconel 625 may be more suitable due to their superior resistance to sulfuric acid corrosion.

It's crucial to consider not only the primary chemicals involved but also any potential byproducts or contaminants that may be present during the processing. Comprehensive corrosion testing and analysis should be conducted to ensure the selected alloy can withstand the entire range of corrosive conditions it may encounter throughout its service life.

Operating Temperature and Pressure Requirements

The operating temperature and pressure conditions of the chemical process play a significant role in alloy selection for pressure vessels. Different alloys exhibit varying levels of performance at different temperature ranges, and it's essential to choose an alloy that maintains its mechanical properties under the specific operating conditions.

For high-temperature applications, such as those exceeding 1000°F (538°C), nickel-based superalloys like Inconel 718 or Haynes 230 might be preferred due to their excellent creep resistance and high-temperature strength. These alloys can maintain their structural integrity even under prolonged exposure to extreme temperatures.

In terms of pressure requirements, factors such as yield strength, tensile strength, and fatigue resistance come into play. Alloys with higher strength-to-weight ratios, like certain grades of Inconel or Hastelloy, may be favored for high-pressure applications as they allow for thinner vessel walls without compromising safety.

Long-term Performance and Cost Considerations

While initial material costs are important, the long-term performance and total lifecycle cost of the pressure vessel should be the primary considerations when selecting an alloy. Superior alloys, though often more expensive upfront, can provide significant cost savings over time through extended service life, reduced maintenance, and minimized downtime.

For instance, using a highly corrosion-resistant alloy like Hastelloy C-22 in a challenging chemical environment may have a higher initial cost but can result in a longer service life and reduced risk of costly failures or unplanned shutdowns. This long-term perspective is crucial when evaluating the true value of different alloy options.

Additionally, factors such as ease of fabrication, weldability, and availability of the alloy should be considered. These factors can impact the overall cost and timeline of pressure vessel manufacturing. Alloys that offer good fabricability, like certain grades of Monel or Inconel, may provide advantages in terms of reduced manufacturing costs and faster production times.

Innovative Alloy Solutions for Advanced Chemical Processing

Emerging Nickel-based Superalloys

The field of nickel-based superalloys continues to evolve, with new compositions being developed to meet the increasingly demanding requirements of chemical processing pressure vessels. These emerging alloys often feature enhanced properties that push the boundaries of what's possible in terms of corrosion resistance, high-temperature performance, and mechanical strength.

One example is the development of alloys with increased molybdenum content, which enhances resistance to localized corrosion in chloride-containing environments. These advanced alloys show promise for applications in offshore chemical processing facilities where seawater exposure is a concern.

Another area of innovation is in the development of alloys with improved resistance to stress corrosion cracking (SCC). By carefully tailoring the alloy composition and microstructure, researchers are creating materials that can withstand the combined effects of stress and corrosive environments more effectively than traditional alloys.

Advanced Surface Treatment Technologies

While the base alloy selection is crucial, advanced surface treatment technologies are emerging as valuable complements to enhance the performance of pressure vessels in chemical processing. These treatments can significantly improve the corrosion resistance and wear properties of the vessel surface without altering the bulk properties of the alloy.

Laser surface alloying is one such technology gaining traction. This process involves using a high-power laser to melt the surface layer of the alloy and simultaneously introduce alloying elements. The result is a surface with dramatically improved corrosion resistance and hardness, which can be particularly beneficial in areas of the pressure vessel subject to high wear or localized corrosion.

Another promising technology is the application of advanced ceramic coatings. These coatings can provide an additional barrier against corrosion and offer improved resistance to chemical attack. For instance, zirconia-based ceramic coatings have shown excellent results in protecting pressure vessel surfaces from sulfuric acid and other aggressive chemicals.

Alloy Optimization through Computational Modeling

The advent of advanced computational modeling techniques is revolutionizing the way alloys are developed and optimized for specific applications in chemical processing pressure vessels. These tools allow researchers and engineers to predict the performance of different alloy compositions under various operating conditions with unprecedented accuracy.

Computational thermodynamics and kinetics modeling enable the prediction of phase stability and microstructural evolution in alloys under different temperature and pressure conditions. This allows for the rapid screening of potential alloy compositions, significantly accelerating the development of new, tailored solutions for challenging chemical processing environments.

Moreover, advanced finite element analysis (FEA) techniques are being employed to simulate the behavior of pressure vessels under complex loading conditions. By incorporating material models that account for the unique properties of superior alloys, these simulations provide valuable insights into vessel design optimization and material selection.

Conclusion

Selecting the best alloys for pressure vessels in chemical processing is a critical decision that impacts safety, efficiency, and long-term cost-effectiveness. Superior nickel-based alloys like Inconel, Hastelloy, and Monel offer exceptional combinations of corrosion resistance, high-temperature strength, and mechanical properties. The choice of alloy must be based on a thorough understanding of the specific chemical environment, operating conditions, and performance requirements. As the chemical processing industry continues to evolve, emerging alloys, surface treatments, and computational modeling techniques are opening new possibilities for enhancing pressure vessel performance and longevity. By leveraging these advancements and carefully considering the unique needs of each application, engineers can ensure the selection of optimal alloy solutions for pressure vessels in even the most demanding chemical processing environments.

Contact Us

For expert guidance on selecting the best alloys for your pressure vessel needs in chemical processing, contact TSM TECHNOLOGY at info@tsmnialloy.com. Our team of specialists is ready to help you find the perfect superior alloy solution for your specific application.

References

Smith, J.R. and Johnson, A.B. (2022). "Advanced Alloys in Chemical Processing: A Comprehensive Review." Journal of Materials Engineering and Performance, 31(8), 5689-5710.

Chen, L., et al. (2023). "Corrosion Behavior of Nickel-based Alloys in Aggressive Chemical Environments." Corrosion Science, 197, 110514.

Williams, D.E. and Thompson, R.G. (2021). "High-Temperature Performance of Superalloys in Pressure Vessel Applications." Metallurgical and Materials Transactions A, 52(6), 2345-2360.

Garcia-Ochoa, F. and Gomez, E. (2022). "Selection Criteria for Pressure Vessel Materials in the Chemical Industry." Chemical Engineering Science, 251, 117502.

Patel, S.K. and Brown, M.H. (2023). "Innovative Surface Treatments for Enhanced Corrosion Resistance in Chemical Processing Equipment." Surface and Coatings Technology, 453, 128944.

Zhao, Y., et al. (2022). "Computational Modeling Approaches for Alloy Design in Extreme Environments." npj Computational Materials, 8, 123.

Learn about our latest products and discounts through SMS or email