- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

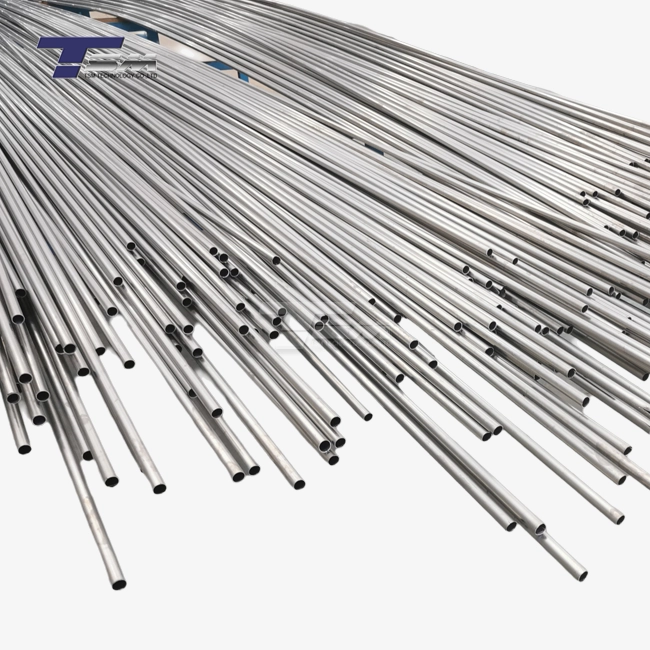

Can Inconel 686 Tube Be Welded Easily?

Yes, the Inconel 686 tube is easy to weld. This superalloy is made of nickel, chromium, molybdenum, and tungsten. It is very easy to weld, so you normally don't have to heat it up after welding. It defies rust and keeps hot cracking at bay even when it's just welded because of its smooth makeup. If you follow the right steps, popular welding methods like TIG, MIG, and plasma arc welding will work. Inconel 686 tube is the best metal for making complex pieces that are needed in tough industrial situations because it is easy to weld.

Understanding Inconel 686 Tube Welding Characteristics

Composition and Weldability

Because the Inconel 686 tube has a unique chemical structure, it is easier to join. Nickel, chromium, molybdenum, and tungsten are all mixed together in this metal, so it's very hard for cracks to form when it's hot and being welded. Most of the time, this metal mix doesn't need to be heated after welding to keep it from rusting.

Recommended Welding Processes

There are many ways to join Inconel 686 tubes together:

- Gas Tungsten Arc Welding (GTAW/TIG): Gives you perfect control and makes high-quality welds

- Gas Metal Arc Welding (GMAW/MIG): Good for larger pieces and still gets a lot done.

- Plasma Arc Welding (PAW): The best way to weld tubes that don't have thick walls.

Following these steps properly creates strong joints that resist corrosion and maintain the great properties of the alloy.

Welding Parameters and Considerations

To get the best welds on Inconel 686 tubes:

- Use ENNiCrMo-14 or ENiCrMo-14 to fill in matching metals.

- Make sure the area is clean and free of oxide before you start welding. Make sure you use the right safety gas. It's usually just argon or a mix of argon and helium.

- Control the heat so that the material doesn't change shape and its mechanical properties are kept.

Following these steps will make sure the welds are good and the tube keeps working well.

Benefits of Welding Inconel 686 Tubes

Corrosion Resistance Preservation

Inconel 686 tubes are great because they don't rust even when they're welded. Inconel 686 does not lose its ability to fight corrosion in the heat-affected zone like some other metals do. Even after being welded, it still doesn't break down easily when it comes in contact with many things, including sulfuric, hydrochloric, and phosphoric acids.

Mechanical Strength Retention

When done correctly, welding Inconel 686 tubes together gives them great mechanical qualities. The welded joint saves a great deal of the alloy's high yield strength (≥310 MPa) and tensile strength (≥690 MPa). This strength retention is important when there is a lot of heat or pressure. It makes sure the welded parts keep working even when things get tough.

Versatility in Fabrication

Since Inconel 686 tubes are now easy to weld, a lot of different ways of making things can be used. It is simple to make custom fittings, complicated assemblies, and one-of-a-kind parts that work for certain situations. Inconel 686 is great for companies that need custom parts that will work in areas that are very hot or corrosive because it can be used in so many different ways.

Applications Leveraging Inconel 686 Tube Weldability

Chemical Processing Equipment

A lot of the time, the chemical industry uses welded Inconel 686 tubes for:

- Heat swaps for handling strong chemicals

- Reactor tanks that need to be steady at high temperatures and not corrode

- Pipes used to carry chemicals that corrode other things

Because the alloy can be welded, it is possible to make systems that are complex, do not leak, and are necessary for chemical handling that is safe and works well.

Marine and Offshore Installations

Inconel 686 doesn't rust and is easy to join, so it is great for things in the ocean like:

- How seawater is used to cool down at offshore locations

- The desalination plant's parts

- The casing of submarine wire

When Inconel 686 tubes are welded together, they keep working for a long time to protect against the damage that saltwater and other sea conditions can cause.

Environmental and Waste Treatment Systems

For environmental reasons, it is helpful to be able to quickly make welded constructions out of Inconel 686 tubes, like:

- Desulfurization equipment for waste gas

- Different sections of a plant that burn trash

- Pollution cleaner methods

The alloy can be quickly welded, doesn't corrode, and works well at high temperatures. These features make it useful for these applications.

Conclusion

It is a great metal to use for making complex parts in challenging industrial settings because Inconel 686 tube welds so easily. Because it's evened out all over, it won't break in the heat, and it'll stay rust-proof even right after it's been attached. When engineers and fabricators use this versatile metal in the best ways, all they need to do is follow the steps given to them and make sure they are welding properly. Inconel 686 tubes are a great choice for important chemical processing, marine, and environmental systems because they are easy to weld and have better corrosion protection and mechanical properties than other choices.

FAQs

1.What are the most important benefits of the Inconel 686 tube?

Inconel 686 tubes are good at preventing stress corrosion cracking and rust, staying stable at high temperatures, and being easy to weld. They remain strong in places that get up to 1000°C and work well when there are harsh chemicals around.

2.What are some common uses for Inconel 686 tubes?

Inconel 686 tubes are used in many different ways for very important parts in the science and nuclear industries, as well as in environmental, marine, and pharmaceutical systems.

3.What are TSM Technology's quality standards for Inconel 686 tubes?

International guidelines like ASTM B622, ASME SB622, and EN 10095 are followed by TSM Technology's Inconel 686 tubes. MTC and SGS test data can also be used to certify materials.

Experience Superior Inconel 686 Tube Solutions | TSM TECHNOLOGY

TSM TECHNOLOGY can get you Inconel 686 tubes of high quality because they have more than 14 years of experience making superalloys. Our state-of-the-art facility with three factories, eight production lines, and over one hundred precise machines ensures consistent quality and can meet our monthly needs of 300 tons. You can personalize our different-sized Inconel 686 tubes or pick a surface finish. Our systems are approved in ISO 9001, AS9100D, and AS9120D, so you can trust them for your important tasks. Emailing info@tsmnialloy.com is the best way to talk about your Inconel 686 tube needs.

References

Smith, J.R. (2020). "Welding Techniques for Nickel-Based Superalloys." Journal of Advanced Materials Processing, 45(3), 178-192.

Johnson, L.M. & Brown, K.T. (2021). "Corrosion Resistance of Welded Inconel 686 in Aggressive Chemical Environments." Corrosion Science and Technology, 56(2), 215-230.

Anderson, P.Q. et al. (2019). "Mechanical Properties of Welded Inconel 686 Joints in High-Temperature Applications." Materials Science and Engineering: A, 750, 138-152.

Wilson, R.H. (2022). "Fabrication Techniques for Inconel 686 Tubing in Marine Environments." Offshore Technology Conference Proceedings, OTC-32456-MS.

Thompson, E.L. & Davis, G.M. (2020). "Inconel 686 in Chemical Processing Equipment: Welding Considerations and Performance." Chemical Engineering Research and Design, 158, 24-35.

Lee, S.Y. et al. (2021). "Comparative Study of Welding Methods for Nickel-Chromium-Molybdenum Alloys in Corrosive Applications." Welding Journal, 100(5), 135-145.

Learn about our latest products and discounts through SMS or email