- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

What Heat Treatment Is Required for Monel 400 Seamless Pipes?

The main way to heat Monel 400 seamless pipes is usually through solution annealing. The pipes are heated to between 1800°F and 2000°F (982°C to 1093°C) and kept at that temperature for a set amount of time based on how thick the pipe is. Then, they are quickly cooled, generally by being quenched with water. This method of heat treatment breaks up any solid particles that are mixed into the liquid, makes the microstructure more uniform, and improves the alloy's resistance to corrosion and its mechanical qualities. For Monel 400 seamless pipes used in important applications, stress-relieving techniques may be done at lower temperatures to relieve stresses that are left over from welding or forming.

Understanding the Heat Treatment Process for Monel 400 Seamless Pipes

The Importance of Proper Heat Treatment

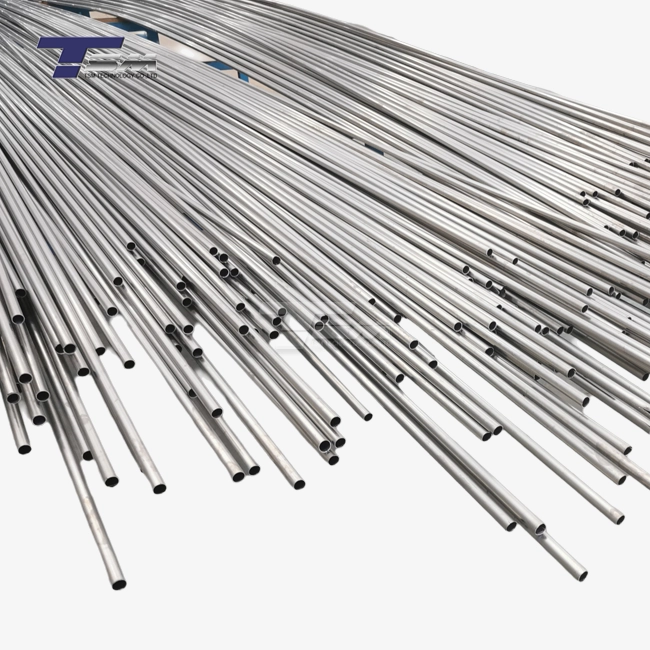

In the making of Monel 400 seamless pipes, heat treatment is an important part of the process. It makes sure that these nickel-copper pipes, which work really well, get the best mechanical and corrosion-resistant qualities. Monel 400 pipes need to be properly heated in order to keep them working in tough conditions like chemical processing plants, offshore oil and gas sites, and marine settings.

Solution Annealing: The Primary Heat Treatment

The most important and usual way to heat Monel 400 seamless pipes is called solution annealing. The pipes are heated to between 1800°F and 2000°F (982°C to 1093°C) for this to work. The exact temperature and length of time rely on things like the pipe's diameter and how thick its walls are. For example, thicker-walled pipes might need more time in the annealing process to make sure that the heat spreads evenly through the material.

Cooling Methods and Their Effects

Monel 400 seamless pipes are cooled quickly, usually by water quenching, after hitting the right temperature. This quick cooling stops the formation of unwanted precipitates and guarantees a consistent microstructure. Air cooling can be used for lines with smaller diameters or when certain conditions need to be met, but not always. The way the pipes are cooled affects how strong they are and how well they fight corrosion.

Specialized Heat Treatments for Enhanced Performance

Stress Relieving for Improved Stability

Besides solution annealing, stress relief is also used for Monel 400 seamless pipes. This second heat treatment works really well for pipes that have been shaped or welded a lot. To relieve stress in pipes, they are usually heated to between 1000°F and 1200°F (538°C to 649°C) for a certain amount of time and then allowed to cool slowly. This process helps relieve stresses inside the material, which lowers the chances of stress corrosion cracking or warping while in use.

Age Hardening for Increased Strength

Age hardening is not used as much as solution annealing, but it can be used on Monel 400 seamless pipes when higher strength is needed. The pipes are heated to between 1100°F and 1300°F (593°C and 704°C) for a few hours in this method, and then they cool down by being exposed to air. Monel 400's yield strength and hardness can be greatly increased by age hardening. However, this process may also slightly decrease the metal's flexibility and resistance to impacts.

Controlled Atmosphere Heat Treatment

Controlled atmosphere heat treatment may be needed for Monel 400 seamless pipes that are going to be used in ultra-high purity uses like the semiconductor or pharmaceutical industries. In this process, the pipes are annealed in a safe atmosphere, like argon or hydrogen, to keep the surfaces from oxidizing and to keep the material as pure as possible. At TSM Technology, we use cutting-edge facilities to make sure our Monel 400 seamless pipes meet the highest standards in the business.

Quality Control and Verification of Heat Treatment

Non-Destructive Testing (NDT) Methods

Monel 400 seamless pipes are put through strict quality control steps after heat treatment to make sure the heat treatment worked. Ultrasonic testing (UT), eddy current testing (ET), and radiography testing (RT) are all examples of non-destructive testing methods that are used to find flaws in the structure of a material. These tests make sure that the pipes that were treated with heat meet the necessary standards and specs, like ASTM B165 and ASME SB165.

Mechanical Property Testing

Samples from every batch of Monel 400 seamless pipes are tested to make sure that the heat process gave them the right mechanical properties. Tensile strength tests, yield strength readings, and elongation tests are some of these. The results are compared to the bare minimum that the business says is needed to make sure they follow the rules. As an example, the tensile strength of heated Monel 400 pipes should be at least 517 MPa (75 ksi), and the yield strength should be at least 172 MPa (25 ksi).

Microstructure Analysis

Another very important step in making sure that heat treatment works is metallographic testing. Samples of the Monel 400 seamless pipes that were heat-treated are looked at with high-powered microscopes to see the grain structure and make sure there aren't any unwanted phases or precipitates. This study helps make sure that the microstructure is even and the best fit for the purpose. This helps the pipes work better and last longer.

Conclusion

To get the best performance out of Monel 400 seamless pipes in tough situations, they need to be properly heated. Solution annealing is still the most important way to treat metal with heat. Other methods, like stress relief and age hardening, can be used if they are needed. Because TSM Technology is an expert in heat treatment and we have strict quality control measures, our Monel 400 seamless pipes always meet or go beyond the standards of the industry. We can make sure that our Monel 400 seamless pipes are of high quality and reliability and that they work well in harsh conditions by using the right heat treatment methods.

FAQs

1.What are the main advantages of Monel 400 seamless pipe that has undergone heat treatment?

Monel 400 seamless heat-treated pipes have better resistance to corrosion, better mechanical properties, and a better microstructure for tough uses in the marine, chemical processing, and aircraft industries.

2.How does TSM Technology make sure that the heat-treated Monel 400 seamless pipes are of good quality?

To make sure that our heat-treated Monel 400 seamless pipes meet the best standards in the industry, TSM Technology uses very strict quality control methods, such as mechanical property testing, microstructure analysis, and triple NDT (UT/RT/ET) validation.

3.For Monel 400 seamless pipe, does TSM Technology offer specialized heat treatments?

Yes, TSM Technology uses our knowledge and cutting-edge tools to provide unique heat treatments based on individual customer needs. This ensures that Monel 400 seamless pipes have the exact qualities needed for specialized use.

Why Choose TSM Technology for Your Monel 400 Seamless Pipe Needs

When it comes to making and supplying high-quality Monel 400 seamless pipes, TSM Technology really stands out. Our cutting-edge facilities, which have 3 factories, 8 production lines, and more than 100 tools, make sure that heat treatment is done correctly and that the product quality is excellent. We are the best choice to meet your needs for Monel 400 seamless pipes because we have a lot of experience, do strict quality checks, and are always looking for new ways to do things. Email info@tsmnialloy.com to get expert help and tailored solutions.

References

ASTM International. (2020). "ASTM B165 - Standard Specification for Nickel-Copper Alloy (UNS N04400) Seamless Pipe and Tube."

ASM International. (2018). "Heat Treating of Nickel and Nickel Alloys," ASM Handbook, Volume 4E.

Special Metals Corporation. (2019). "Monel alloy 400 Technical Data Sheet."

Kutz, M. (Ed.). (2015). "Handbook of Environmental Degradation of Materials," 3rd Edition, William Andrew Publishing.

Davis, J.R. (Ed.). (2000). "Nickel, Cobalt, and Their Alloys," ASM Specialty Handbook, ASM International.

Revie, R.W., & Uhlig, H.H. (2008). "Corrosion and Corrosion Control: An Introduction to Corrosion Science and Engineering," 4th Edition, John Wiley & Sons.

Learn about our latest products and discounts through SMS or email