The 201 nickel sheet can be safely used in food preparation because it has great corrosion protection and high purity. This commercially pure worked nickel metal meets FDA rules and works better in places where cleanliness is very important. It is non-reactive with food, conducts heat very well, and is resistant to acids and alkalis that are widely used in food preparation. These make it an ideal choice for making equipment used in the food business.

Understanding Nickel 201 Sheet and Its Properties

Material Composition and Metallurgical Characteristics

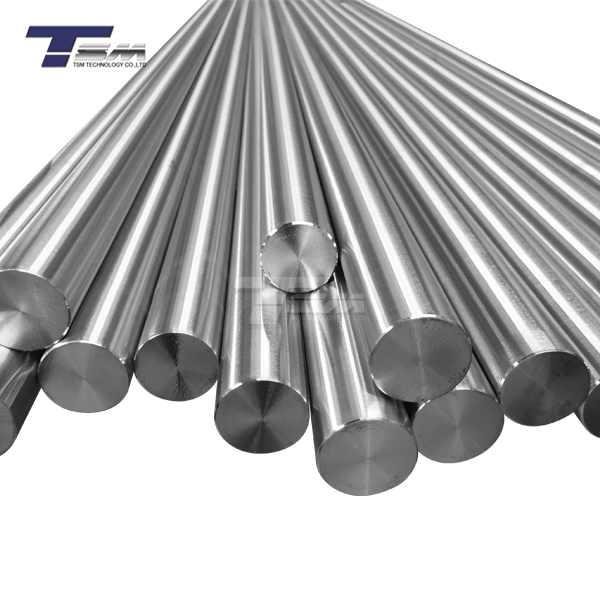

Nickel 201 is a commercially pure grade of nickel. It has a minimum nickel value of 99.0%, and it is classified under UNS N02201. This composition has high purity and offers great strength, ductility, and resistance to many types of corrosion. This makes it a useful material for a wide range of demanding uses. The metallurgical structure has great mechanical qualities, such as high tensile strength and good hardness. These are important for making long-lasting food preparation equipment that can handle constant use.

The material stays structurally sound over a wide range of temperatures, from very cold to hot, up to the 1435°C melting point. With a density of 8.89 g/cm³ and thermal conductivity of 70 W/m·K, Nickel 201 shows great heat transfer qualities necessary for thermal processing applications. These basic features give us a good way to judge whether or not it is appropriate for food applications where safety, reliability, and consistent performance are most important.

Mechanical Performance Standards

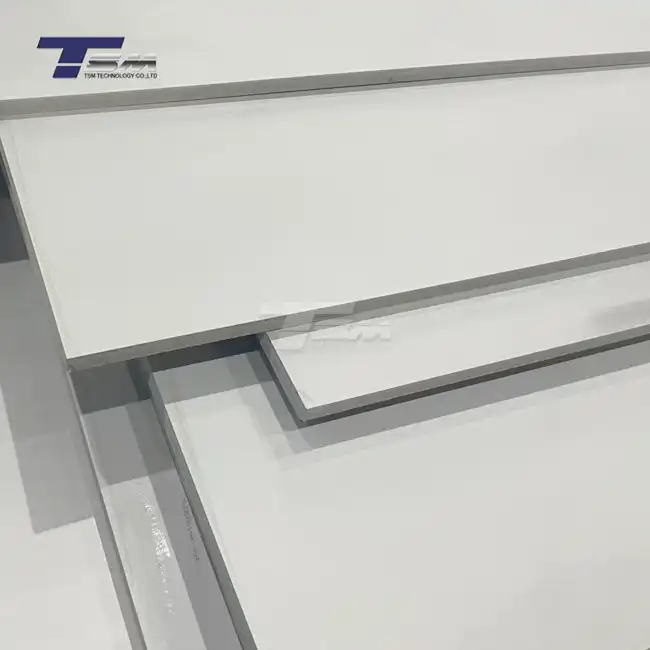

TSM Technology makes Nickel 201 sheets that meet global standards like ASTM B162, ASME SB162, and EN 10095. To make sure that all widths from 0.5mm to 50mm have the same quality, our production sites use modern vacuum arc furnaces and 2,500-ton forging presses. The material has great formability in hot-rolled, cold-rolled, and annealed ends. This lets builders make sure that different parts of food processing machines are exactly right.

Corrosion Resistance and Temperature Tolerance in Nickel 201

Chemical Stability in Food Processing Environments

Nickel 201 is great at resisting corrosion because it is very pure and chemically stable, which is especially useful in food preparation where the environment is slightly acidic or basic. The metal shows great resistance to oxidation and corrosion at high temperatures, which are situations that are common in heat exchanges, pasteurization equipment, and industrial cooking systems. Its dependability under different processing conditions makes it a great choice for foods that have fruit acids, cheese, or other chemically active ingredients.

Understanding individual environmental limitations for 201 nickel sheet remains important for long-term performance optimization. Nickel 201 works very well in most food processing settings. But in strongly oxidizing situations or when sulfur chemicals are around at high temperatures, it doesn't work as well. These things affect how equipment is designed and how repair is done, giving you important information about why procurement professionals are choosing this material more and more for heating and hygienic uses.

Thermal Performance Characteristics

The thermal qualities of Nickel 201 make it particularly useful in food processing applications needing precise temperature control. It has an electrical resistivity of 9.6 µΩ·cm and better thermal conductivity, which makes it easier for heat to move in everything from scalding to freeze-drying. The material keeps its shape when the temperature changes, which means that equipment in tough production settings doesn't have to be as often and can work for longer.

Heat Treatment and Fabrication Considerations

Processing Protocols for Food Grade Applications

Heating Nickel 201 changes its mechanical strength and its ability to resist corrosion in a big way. Processes of annealing improve ductility and workability, which helps with manufacturing and keeps the material's natural ability to fight corrosion. The right way to use heat on the material makes it stronger without hurting its ability to fight rust, which is important for keeping the food safety standards during the equipment's lifetime.

Fabrication methods like welding, forming, and surface finishing need special techniques to keep food-grade qualities. TSM Technology uses specialized surface treatments like grinding and anodizing in their production processes. These methods make sure that the surfaces are as good as possible for food contact. Our quality control tools keep an eye on these steps to make sure that all of the production runs have the same results.

Quality Assurance in Manufacturing

Our thorough quality checking methods use non-destructive testing techniques, chemical composition analysis, mechanical property testing, and microstructure study. These tough rules make sure that every 201 nickel sheet can be used in food processing applications. Material certifications, like MTC and SGS test reports, show full traceability so that the rules can be followed.

Assessing Nickel 201 Sheet for Food Processing Applications

Regulatory Compliance and Food Safety Standards

Nickel 201 is an accepted food-grade material because it meets important food safety rules and laws, including those set by the FDA in the United States and the EU in Europe. Its chemical stability means that it doesn't combine with food, which lowers the risk of contaminating the product and keeps it safe and high quality. The way the material is made and the things that are in it meet Good Manufacturing Practices (GMP) standards that are important for working in the food business.

The smooth surface makes it easy to clean and follow cleanliness rules that are important for keeping the working areas clean. This cleanability factor makes it easier for systems used in current food preparation plants to clean bacteria off surfaces and do cleaning-in-place (CIP). Procurement experts, on the other hand, must keep possible issues in mind, such as the need to properly prepare the area to lower the risk of contamination and worries about nickel allergies in some groups of people.

Hygienic Design Considerations

Nickel 201's lack of magnetic properties gives extra benefits in food preparation settings that use magnetic contamination monitoring systems. The way TSM Technologies makes different surface finishes keeps the material's great engineering qualities and makes sure that it stays clean, even after long periods of use.

Comparison: Nickel 201 Sheet vs Alternative Materials for Food Processing

Performance Against Stainless Steel Alternatives

Nickel 201 has better protection to corrosion and heat than widely used stainless steels, such as grades 304 and 316, especially in harsh conditions or when the temperature is very high. Nickel 201 is better than 304 and 316 stainless steels at resisting some organic acids and oxidizing agents, so it should be used in specialized settings like making citrus products, wine, or pharmaceutical-grade food ingredients.

Nickel 201's thermal conductivity benefits are especially useful in situations where quick heat transfer or exact temperature control is needed. Different materials, like copper metals, work well with heat but don't prevent rust well enough for direct food contact. This method of judging two or more things side by side helps B2B buyers choose the best products based on how they will be used, how well they need to work, and how much they will cost in the long run.

Cost-Benefit Analysis for Specialized Applications

Nickel 201 such as 201 nickel sheet may have higher material costs at first than regular stainless steels, but its better performance makes it worth the cost in important situations. The total cost of ownership for demanding food production processes is good because it has better product quality, longer service life, and lower maintenance needs.

Procurement Insights for Nickel 201 Sheets in Food Industry

Specification Requirements and Supply Chain Considerations

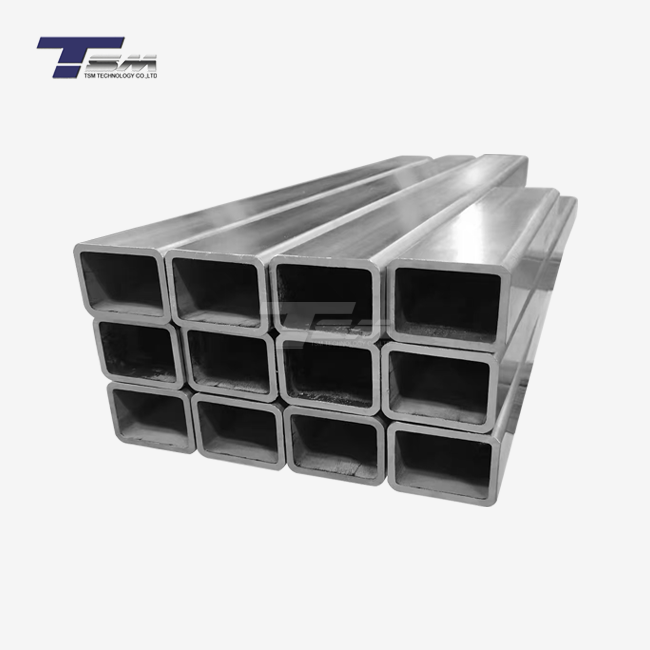

Nickel 201 sheets used in food processing usually have widths between 0.5 mm and 6 mm for most tools. People who work in procurement should know this. The standard and special sheet sizes meet a range of equipment design needs while keeping the quality and purity of the material for use in food contact applications.

It is still very important to choose trustworthy vendors with known credentials and a history of reliable service to make sure that quality and on-time delivery always happen. With planned stocks of raw materials and smart storage systems, TSM Technology's global supply network gives production plans the dependability they need to stay on track. We can produce 1,200 tons of certified material for big projects every year, and our quality control methods make sure that the material is always available.

Vendor Evaluation Criteria

When choosing a supplier, making sure they follow certifications like ISO 9001/13485, AS9100D, and NADCAP, as well as looking into their technical support, compliance, and customization capabilities are all very important. TSM Technology's broad strategy helps buying teams define material specs and get the most out of their applications by offering free samples, custom processing, and focused tech support.

Practical Applications and Case Studies in Food Processing

Equipment Applications and Performance Data

Nickel 201 sheet is useful in many types of food preparation equipment, like storage tanks, heat exchanges, conveyor systems, and specialized processing machines. The corrosion resistance and longevity of the material mean that it can be used for a long time without needing to be serviced. This makes the overall process more efficient and lowers costs throughout its lifetime.

In acidic production conditions, service life is increased by 30–50% compared to standard materials, according to real-world examples. Customers always talk about how strong the material is, how easy it is to clean, and how well it keeps the surface quality even after long periods of use. These factors are very important for keeping food safety standards high and making production more efficient.

Best Practices for Implementation

Recommended ways to handle, clean, and check things make them last longer and work better. Proper fitting techniques, compatible joining methods, and proper cleaning processes guarantee optimal results throughout the equipment's operating life. These rules help people who work in procurement write detailed specs and upkeep schedules for Nickel 201 uses.

TSM Technology: Your Trusted Nickel 201 Sheet Supplier

TSM Technology is a well-known maker of high-quality Nickel 201 sheets. They provide high-performance metal options for precision engineering fields around the world. Since we started in 2011, we've built up a lot of amazing infrastructure. Our Shaanxi production base covers 3,200 square meters and has three high-tech plants with eight production lines and more than 100 machines. We are fully vertically integrated, with vacuum arc furnaces and 2,500-ton forging presses. This helps us keep quality high and compete with others in terms of delivery times.

Our promise of quality goes beyond what we can make to include quality assurance methods that meet ISO 9001/13485, AS9100D, and NADCAP standards. We help our customers meet the rules by giving full material approval that includes MTC and SGS test results. We are the most desired partner for difficult food processing applications that need the highest material standards because of our global supply chain dependability, personalized processing options, and quick technical support.

Conclusion

Nickel 201 is the best option for food preparation uses that need to be thermally resistant, comply with regulations, and not corrode. It is perfect for tough processing settings because its high-purity makeup, great mechanical qualities, and history of safety in food use. Even though the upfront costs might be higher than standard options, these products' better performance, longer lifespan, and lower upkeep needs make them a very good choice for important uses. When procurement workers look at material choices for food processing equipment, they should think about Nickel 201's special benefits in areas where performance and safety are very important.

FAQs

1.Is Nickel 201 sheet safe for direct contact with food products?

Yes, Nickel 201 sheet is approved for direct food contact applications. It meets FDA regulations and EU standards for food-grade materials. The high-purity composition (99.0% minimum nickel content) ensures chemical stability and non-reactivity with food substances, making it safe for processing equipment that comes into direct contact with food products.

2.How does the corrosion resistance of Nickel 201 compare to 304 stainless steel in acidic food environments?

Nickel 201 offers superior corrosion resistance compared to 304 stainless steel in acidic food processing environments. While 304 stainless steel can experience pitting and crevice corrosion in organic acids commonly found in food processing, Nickel 201's high purity provides excellent resistance to various acids and maintains surface integrity over extended exposure periods.

3.What are the typical delivery times and minimum order quantities for bulk orders of Nickel 201 sheet?

TSM Technology typically processes bulk orders within 2-4 weeks depending on specifications and quantity requirements. Our 1,200-ton annual capacity and strategic inventory management enable flexible order fulfillment. We accommodate various order sizes and offer customized processing services. Contact our team for specific lead times based on your requirements and specifications.

Partner with TSM Technology for Premium Nickel 201 Sheet Solutions

Ready to enhance your food processing operations with high-quality 201 nickel sheet materials? TSM Technology offers comprehensive solutions including customized dimensions, specialized surface treatments, and complete material certification packages. Our experienced engineering team provides technical support throughout the specification and implementation process, ensuring optimal material selection for your specific applications. As a trusted nickel 201 sheet manufacturer, we guarantee consistent quality, competitive pricing, and reliable delivery schedules. Contact us at info@tsmnialloy.com for detailed specifications, samples, and personalized consultation to optimize your procurement strategy.

References

American Society for Testing and Materials. "Standard Specification for Nickel-Copper-Aluminum Alloy Plate and Sheet." ASTM B162-22, 2022.

Food and Drug Administration. "Food Additive Status List: Metals and Alloys for Food Contact Applications." FDA Guidance Document, 2021.

European Food Safety Authority. "Scientific Opinion on the Safety Assessment of Nickel in Food Contact Materials." EFSA Journal, 2020.

Singh, R. Paul, and Dennis R. Heldman. "Introduction to Food Engineering: Materials and Equipment Selection." Academic Press, 2019.

Metals Handbook Committee. "Corrosion Resistance of Nickel Alloys in Food Processing Environments." ASM International, 2021.

International Organization for Standardization. "Food Safety Management Systems: Requirements for Materials in Food Processing." ISO 22000:2018 Standard, 2018.

_1739071430258.webp)