To weld Nickel 201 without breaking or porosity, one must understand this commercially pure nickel alloy's unique traits, properly prepare the material, and have exact control of the welding settings. The key is to carefully control the amount of heat used, keep the shielding gas flow at the right level, make sure the surface is clean, and choose the right welding methods, like TIG or plasma welding. Success depends on managing thermal stresses by preheating correctly when needed and using post-weld heat treatment to get rid of leftover stresses that might cause flaws.

Understanding the Challenges When Welding Nickel 201

Welding Nickel 201 is not always easy to do, and can have a big effect on the quality of the weld and how well the part works. This nickel metal has at least 99% nickel. It is commercially pure and has great protection against corrosion and great heat conductivity, which makes welding more difficult. Since the material has a high thermal conductivity of 70 W/m·K, heat moves away from the weld quickly. This could cause partial fusion or the need for a higher heat input, which can cause other issues.

Material Properties That Affect Welding

Nickel 201's physical qualities have a direct effect on how welding works. This metal has a density of 8.89 g/cm³ and melts at 1435°C, so the temperature needs to be carefully controlled during the welding process. Its electrical resistance is 9.6 µΩ·cm, which affects how stable the arc is. Also, because the material is very ductile, it can bend if thermal expansion isn't managed correctly. Understanding these features helps engineers figure out what kinds of problems might happen with welding. They can then change the settings to make sure everything goes smoothly.

Common Defect Types in Nickel Alloy Welds

In Nickel 201 welds, cracking usually shows up as hot cracking while the weld is setting or as cold cracking because of pressures that stay in the metal. As gases are stuck in the weld metal, porosity is often the result of pollution, poor shielding, or the metal absorbing moisture. Both flaws hurt the mechanical qualities that are needed for difficult uses in aircraft, chemical processing, and marine settings where material integrity is very important.

Root Causes of Cracking and Porosity in Nickel 201 Welds

Finding the reasons why weld flaws happen lets you come up with ways to stop them before they happen. When metals are mixed, they have a big effect on how defects form, especially when welding cools and solidifies. The quick temperature changes that are a normal part of welding cause internal stresses by creating temperature differences across the material. These stresses can go beyond the material's yield strength, which may cause cracks to start.

Thermal Stress Mechanisms

A big difference in thermal growth between the weld metal and the base material causes stress to build up in certain areas. Nickel 201 has a very high ability to conduct heat, which makes this problem worse by causing big differences in temperature during welding. If the temperature drops quickly, stresses can get trapped in the nanoscale. This can cause cracks long after the welding is done. Understanding how heat and temperature affect objects helps people choose the right cooling rates and post-weld treatments.

Contamination and Surface Preparation Issues

Nickel metal welds become porous mostly because of things on the surface. When welding, oils, oxides, moisture, and other materials from outside the project can create gases that get stuck in the weld pool when it hardens. Even very small amounts of pollution can lead to serious issues with porosity. Nickel 201 is more affected by pollution than other nickel-based alloys because it is commercially clean and does not have other metals mixed in.

Welding Parameter Interactions

The way welding current, voltage, movement speed, and shielding gas makeup work together can affect how defects form. While not enough heat can cause cold cracking and partial fusion, too much heat can lead to grain growth and hot cracking susceptibility. The flow rates of the shielding gas must be set so that there is enough protection and no turbulence that can trap gases in the atmosphere.

Best Practices and Welding Techniques to Prevent Cracking and Porosity

Using well-known best practices makes weld flaws much less likely in Nickel 201 uses. Before you start welding, you need to make sure that all possible sources of contamination are dealt with and that the joint is in the best possible shape. This is an important part of the process that will set you up for success. During the welding process, parameters must be carefully controlled and monitored to keep the quality the same all the time.

Pre-Welding Preparation Procedures

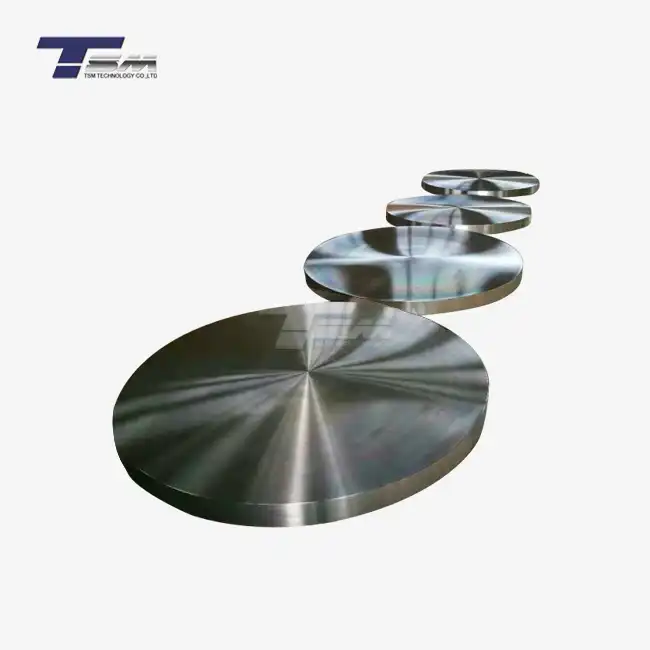

A deep clean of the surface gets rid of things that could make gaps or affect how well the weld penetrates. If you do chemical cleaning with the right solvents and then mechanical cleaning with stainless steel brushes, you can be sure that the surface is in the best possible condition. During joint preparation, the pieces must fit together well with only a small amount of space between them so that the risk of partial fusion is lowered. When you use TSM Technology's Nickel 201 sheets, our sanding and anodizing methods give you a smooth surface that is great for starting to weld.

Optimal Welding Parameter Selection

Here are the important welding settings that make sure Nickel 201 welds are not broken:

- Current Control: Maintain consistent amperage appropriate for material thickness, typically 80-120 amps per inch of thickness for TIG welding applications

- Travel Speed: Control welding speed to ensure proper heat input without overheating, usually 6-10 inches per minute for most applications

- Shielding Gas: Use high-purity argon or helium-argon mixtures with flow rates of 15-25 cubic feet per hour to prevent atmospheric contamination

- Arc Length: Maintain short arc lengths of 1-3mm to ensure stable welding conditions and minimize heat-affected zone width

These groups of parameters give you a rough idea of where to start. You should make changes based on the needs of your program and how the joints are set up. Nickel 201 has a high thermal conductivity, so it often needs more heat than stainless steel when welding.

Post-Weld Treatment Strategies

By getting rid of leftover stresses and making the best possible microstructure, post-weld heat treatment can make a big difference in the quality of a weld. Nickel 201 is useful for chemical processes because it resists corrosion. Stress relief methods at 600–700°C help keep these qualities by stopping cracks before they happen. To get the right effects, the length of time and cooling rate of heat treatment must be carefully handled.

Comparing Nickel 201 Welding With Other Alloys: Implications for Procurement

Nickel 201 welding is similar to some materials and different from others. When buying workers know these facts, they can make smart choices about what materials to use and what suppliers need to do. This comparison gets more important when looking at options for certain uses or when trying to get the best prices while keeping speed up.

Nickel 201 vs. Nickel 200 Welding Characteristics

Nickel 201 has a lower maximum carbon content than Nickel 201, so it is easier to weld and less likely to crack when hot. Because of this difference, Nickel 201 is better for welding fabrications, especially when they are used in high-temperature conditions where carbide precipitation could make them more vulnerable to rust. The welding steps for both metals are still the same, but Nickel 201 has bigger parameter windows and is better at handling small differences in how the welding is done.

Performance Comparison with Stainless Steel and Superalloys

Nickel 201 resists rust better than stainless steel in many chemical settings, but because it conducts heat better, it needs to be welded more carefully. Inconel is a superalloy that has better strength at high temperatures, but it is harder to weld because of how complicated its science is and how easily it cracks. When procurement choices are made, these performance trade-offs should be compared to certain application needs and welding skills.

Procuring High-Quality Nickel 201 for Reliable Welding

Choosing the right source and material specs has a big effect on how well welding works and how well the whole project turns out. Nickel 201 of good quality has a constant chemical makeup, the right mechanical properties, and a surface that makes it easy to join. Procurement plans should focus on what suppliers can do, how they certify their products, and the extra services they offer that help with welding.

Supplier Qualification and Certification Standards

To make sure products meet the needs of the aerospace and military industries, TSM Technology holds a wide range of credentials, such as ISO 9001/13485, AS9100D, and NADCAP. Our modern vacuum arc furnaces and exact rolling machines make sure that all of the material in every output lot has the same qualities. For important uses where paperwork is needed, SGS test results and material test certificates (MTC) make sure that everything can be traced back to its source.

Material Specifications for Welding Applications

When procuring Nickel 201 for welding, consider these critical specifications that affect weld quality and performance:

- Surface Condition: Specify appropriate surface treatments (hot-rolled, cold-rolled, or annealed) based on welding requirements and final application needs

- Thickness Tolerance: Ensure precise thickness control (available 0.5-50mm from TSM Technology) to maintain consistent welding parameters across joints

- Chemical Composition: Verify compliance with ASTM B162, ASME SB162, or EN 10095 standards for guaranteed weldability and performance

- Mechanical Properties: Confirm yield strength and ductility values meet application requirements, particularly for pressure vessel or structural applications

These standards make sure that the materials are consistent, which helps with predictable welding results and lowers the need for lengthy parameter development or qualification testing.

Conclusion

To get perfect Nickel 201 welds, you need to know about the material, use the right welding methods, and get good materials from trusted sources. Choosing the right parameters, keeping the surface clean, and using the right post-weld processes when needed are all ways to control thermal pressures that can lead to success. When this commercially pure metal is used correctly, it has great resistance to rust and can be easily welded together. To make sure that the welding results are always the same and that the parts work as well as possible in difficult industrial settings, procurement professionals should focus on getting sellers with known quality systems and technical knowledge.

FAQs

1.What is the ideal welding process for Nickel 201 to minimize defects?

TIG (GTAW) welding is typically the preferred process for Nickel 201 due to its precise heat control and excellent shielding capabilities. This process allows for careful management of heat input while maintaining the inert atmosphere necessary to prevent contamination. For thicker sections, plasma welding can provide deeper penetration while maintaining similar quality levels. MIG welding is possible but requires more careful parameter control and high-quality filler materials.

2.How does heat input affect the likelihood of cracking in Nickel 201 welds?

Excessive heat input can cause grain growth in the heat-affected zone, making the material more susceptible to hot cracking during solidification. However, insufficient heat input can lead to incomplete fusion and cold cracking due to residual stresses. The key is finding the optimal balance that ensures complete penetration while minimizing thermal stress. Generally, lower heat input with multiple passes produces better results than single high-energy passes.

3.Can Nickel 201 be welded without preheating, and when is preheating necessary?

Nickel 201 can often be welded without preheating, particularly for thin sections and simple joint geometries. Preheating becomes necessary for thick sections (typically over 1 inch), highly restrained joints, or when ambient temperatures are below 60°F. Preheating temperatures of 200-400°F help reduce thermal gradients and minimize residual stresses. The decision should be based on material thickness, joint restraint, and specific application requirements.

Partner with TSM Technology for Superior Nickel 201 Solutions

TSM Technology stands ready to support your critical welding applications with premium Nickel 201 materials and expert technical guidance. Our comprehensive product portfolio includes precision-manufactured sheets, coils, and custom-sized materials that meet the most demanding specifications. With three advanced production facilities, 1,200-ton annual capacity, and complete quality certification, we serve as your trusted Nickel 201 supplier for aerospace, chemical processing, and marine applications. Our technical team collaborates directly with your engineers to optimize welding procedures and material specifications, ensuring defect-free results that enhance your production efficiency. Contact us at info@tsmnialloy.com to discuss your specific requirements and request complimentary material samples for your next project.

References

American Welding Society. "Welding Handbook: Materials and Applications, Part 2." 9th Edition, Volume 4, Chapter on Nickel and Nickel Alloys.

ASM International. "Metals Handbook: Welding, Brazing, and Soldering." Volume 6, Section on Commercially Pure Nickel Welding Procedures.

NACE International. "Corrosion-Resistant Alloy Welding Guidelines for Chemical Process Industries." Publication SP0472, Nickel Alloy Welding Standards.

The Nickel Institute. "Guidelines for Welding Nickel and Nickel Alloys." Technical Literature Review, Welding Parameters and Best Practices.

ASME Boiler and Pressure Vessel Code. "Section IX: Welding and Brazing Qualifications." Guidelines for Nickel Alloy Welding Procedure Specifications.

International Institute of Welding. "Commission IX: Behaviour of Metals Subjected to Welding." Document IIW-IX-2089, Nickel Alloy Weldability Assessment.