Understanding Inconel 625 Sheet Properties and Their Impact on CNC Machining

Composition and Microstructure of Inconel 625

Inconel 625, also known as alloy 625 sheet, is a nickel-chromium-based superalloy renowned for its exceptional properties. Its composition typically includes 58% nickel, 20-23% chromium, 8-10% molybdenum, and smaller amounts of niobium, iron, and other elements. This unique blend yields a complex microstructure that contributes to the alloy's exceptional strength and corrosion resistance. The presence of molybdenum and niobium in the matrix forms stable intermetallic compounds, enhancing the material's resistance to various forms of deterioration and maintaining its strength at elevated temperatures.

Mechanical Properties Affecting Machinability

The mechanical properties of Inconel 625 sheet significantly impact its machinability. With a yield strength ranging from 414-655 MPa and tensile strength between 827-1034 MPa, this alloy exhibits exceptional toughness and resistance to deformation. Its high work-hardening rate poses a particular challenge during machining, as the material's strength increases rapidly under the stress of cutting operations. This phenomenon can lead to premature tool wear and necessitates careful selection of cutting parameters to maintain consistent material removal rates.

Thermal Characteristics and Their Effects on Cutting Processes

Inconel 625's thermal properties play a crucial role in CNC machining challenges. With a melting point of approximately 1350°C and excellent heat resistance, the alloy retains its strength at high temperatures. This characteristic, while beneficial for many applications, complicates the machining process. The material's low thermal conductivity (9.8 W/m·K at room temperature) leads to heat concentration at the cutting zone, potentially causing rapid tool wear and affecting surface finish quality. Machinists must employ strategies to manage heat generation and dissipation effectively to ensure optimal cutting performance and tool longevity.

Overcoming Tool Wear and Optimizing Cutting Parameters

Selecting Appropriate Cutting Tools for Inconel 625

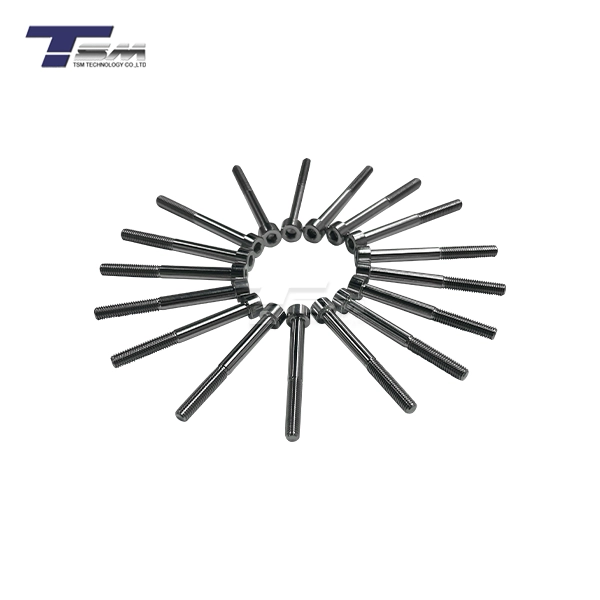

Choosing the right cutting tools is paramount when machining Inconel 625 sheet. Carbide tools with specialized coatings, such as TiAlN or AlCrN, have shown promising results in resisting wear and maintaining edge integrity. Ceramic tools, particularly those reinforced with whiskers, offer excellent performance at high cutting speeds. For certain operations, polycrystalline cubic boron nitride (PCBN) tools may be employed to achieve superior surface finishes and extended tool life. The geometry of the cutting tools also plays a crucial role; positive rake angles and sharp cutting edges help reduce cutting forces and minimize work hardening.

Optimizing Cutting Speed and Feed Rates

Determining optimal cutting parameters for Inconel 625 sheet and alloy 625 sheet machining involves balancing productivity with tool life and surface quality. Generally, lower cutting speeds (20-30 m/min for carbide tools) and moderate feed rates are recommended to mitigate excessive heat generation and tool wear. However, these parameters may vary depending on the specific machining operation and tool material. For instance, when using ceramic tools, higher cutting speeds (100-250 m/min) can be employed to take advantage of their heat resistance properties. Continuous monitoring and adjustment of these parameters are essential to maintain consistent machining performance throughout the tool's life cycle.

Implementing Effective Cooling Strategies

Proper cooling and lubrication are critical in managing the heat generated during the machining of Inconel 625 sheet. High-pressure coolant delivery systems, directing coolant precisely at the cutting edge, have shown significant improvements in tool life and chip control. Cryogenic cooling techniques, using liquid nitrogen or CO2, offer promising results in reducing tool wear and improving surface finish quality. Additionally, minimum quantity lubrication (MQL) systems can be effective in certain applications, providing adequate cooling while minimizing environmental impact. The choice of cooling strategy should be tailored to the specific machining operation, considering factors such as cutting speed, depth of cut, and tool geometry.

Advanced Techniques for Precision Machining of Inconel 625 Sheet

Implementing High-Speed Machining Strategies

High-speed machining (HSM) techniques can be advantageous when working with Inconel 625 sheet, despite the material's challenging properties. By employing higher spindle speeds and feed rates while maintaining shallow depths of cut, HSM can reduce cutting forces and heat generation. This approach often results in improved surface finishes and potentially extended tool life. However, successful implementation requires rigorous process optimization, including the use of advanced CAM software for toolpath generation and robust machine tools capable of maintaining precision at high speeds. Machinists must carefully balance cutting parameters to avoid excessive tool wear while maximizing material removal rates.

Utilizing Vibration-Assisted Machining Techniques

Vibration-assisted machining (VAM) has emerged as a promising technique for enhancing the machinability of difficult materials like Inconel 625 and alloy 625. By introducing controlled, high-frequency vibrations to the cutting tool or workpiece, VAM can improve chip formation, reduce cutting forces, and enhance heat dissipation. This technique is particularly effective in operations such as drilling and milling of Inconel 625 sheet and alloy 625 sheet, where it can significantly reduce built-up edge formation and improve surface quality. The implementation of VAM requires specialized equipment and careful process optimization but can lead to substantial improvements in machining efficiency and tool life when working with this challenging alloy.

Leveraging Advanced Toolpath Strategies

Innovative toolpath strategies play a crucial role in optimizing the CNC machining of Inconel 625 sheet. Trochoidal milling, for instance, involves a circular cutting motion combined with a forward step, allowing for consistent chip thickness and reduced tool engagement. This approach can significantly reduce cutting forces and heat generation, leading to improved tool life and machining efficiency. Similarly, dynamic milling strategies that adjust tool engagement based on real-time cutting conditions can help maintain optimal cutting parameters throughout complex geometries. Implementing these advanced toolpath strategies requires sophisticated CAM software and may necessitate adjustments to cutting parameters, but the benefits in terms of productivity and part quality can be substantial when machining Inconel 625.

Conclusion

Mastering the CNC machining of Inconel 625 sheet demands a comprehensive approach that combines material knowledge, advanced tooling, optimized cutting parameters, and innovative machining strategies. By understanding the unique properties of this superalloy and implementing tailored solutions, manufacturers can overcome the inherent challenges and achieve high-precision, efficient machining results. The continuous evolution of cutting tool technologies, cooling methods, and machining techniques offers promising avenues for further improving the machinability of Inconel 625. As industries continue to push the boundaries of material performance, the ability to effectively machine these advanced alloys becomes increasingly crucial, driving ongoing research and development in the field of precision manufacturing.

FAQs

What are the key challenges in CNC machining Inconel 625 sheet?

The main challenges include rapid tool wear, difficulty in chip breaking, and work hardening during machining. The material's high strength, heat resistance, and low thermal conductivity also contribute to these challenges.

How can tool life be extended when machining Inconel 625?

Tool life can be extended by using appropriate cutting tool materials and coatings, optimizing cutting parameters, implementing effective cooling strategies, and utilizing advanced machining techniques like high-speed machining or vibration-assisted machining.

What cutting parameters are recommended for Inconel 625 sheet?

Generally, lower cutting speeds (20-30 m/min for carbide tools) and moderate feed rates are recommended. However, specific parameters may vary based on the machining operation, tool material, and cooling method used.

Expert Inconel 625 Sheet Machining Solutions | TSM TECHNOLOGY

At TSM TECHNOLOGY, we specialize in providing cutting-edge solutions for CNC machining challenges with Inconel 625 sheet. Our advanced manufacturing capabilities and extensive experience ensure precise, efficient machining of this high-performance alloy. As a leading supplier and manufacturer, we offer premium-quality Inconel 625 products tailored to your specific needs. For expert guidance and superior alloy solutions, contact our team at info@tsmnialloy.com.

References

Ezugwu, E. O. (2005). Key improvements in the machining of difficult-to-cut aerospace superalloys. International Journal of Machine Tools and Manufacture, 45(12-13), 1353-1367.

Polvorosa, R., et al. (2017). Cutting forces prediction in the dry machining of Inconel 718. The International Journal of Advanced Manufacturing Technology, 92(1-4), 451-462.

Thakur, A., & Gangopadhyay, S. (2016). State-of-the-art in surface integrity in machining of nickel-based super alloys. International Journal of Machine Tools and Manufacture, 100, 25-54.

Ulutan, D., & Ozel, T. (2011). Machining induced surface integrity in titanium and nickel alloys: A review. International Journal of Machine Tools and Manufacture, 51(3), 250-280.

Zhu, D., et al. (2013). Evaluation of novel tool materials for machining Inconel 718. Journal of Materials Processing Technology, 213(1), 103-113.

Akhtar, W., et al. (2016). Surface quality in high-speed milling of titanium alloy Ti-6Al-4V and Inconel 718. Materials and Manufacturing Processes, 31(13), 1752-1764.