Understanding Monel 400 and Its Properties

Composition and Characteristics of Monel 400

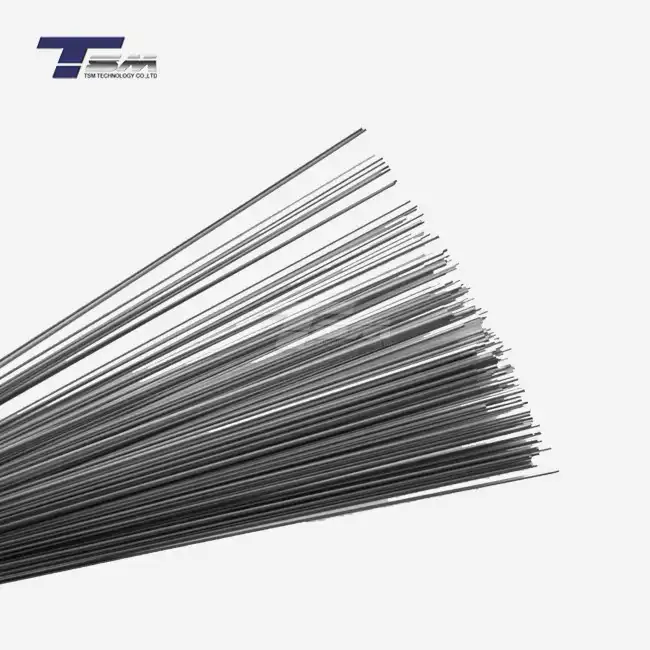

Monel 400 is a nickel-copper alloy renowned for its exceptional corrosion resistance and strength. Typically composed of approximately 63% nickel, 31% copper, and small amounts of iron, manganese, and silicon, this versatile alloy offers a unique combination of properties. The high nickel content contributes to its excellent resistance to reducing environments, while copper enhances its resistance to seawater and many acids.

The Monel 400 round bar exhibits remarkable tensile strength, typically ranging from 70,000 to 85,000 psi in the annealed condition. Its yield strength usually falls between 25,000 and 40,000 psi, depending on the specific heat treatment and processing. The alloy's elongation can reach up to 50%, indicating its impressive ductility and formability.

Applications of Monel 400 Bar

The versatility of Monel 400 bar makes it an excellent choice for various industries. In marine applications, it's used for propeller shafts, valve stems, and pump components due to its resistance to saltwater corrosion. The chemical processing industry relies on Monel bar for heat exchangers, reaction vessels, and piping systems, particularly in environments involving hydrofluoric acid and other corrosive substances.

Aerospace engineers favor Monel 400 round bar for aircraft engine components and fasteners, benefiting from its high strength-to-weight ratio and resistance to high-temperature oxidation. The oil and gas sector utilizes Monel bar in wellhead components, valves, and fittings, where its resistance to sulfide stress cracking is invaluable.

Advantages of Cold Rolling Monel 400

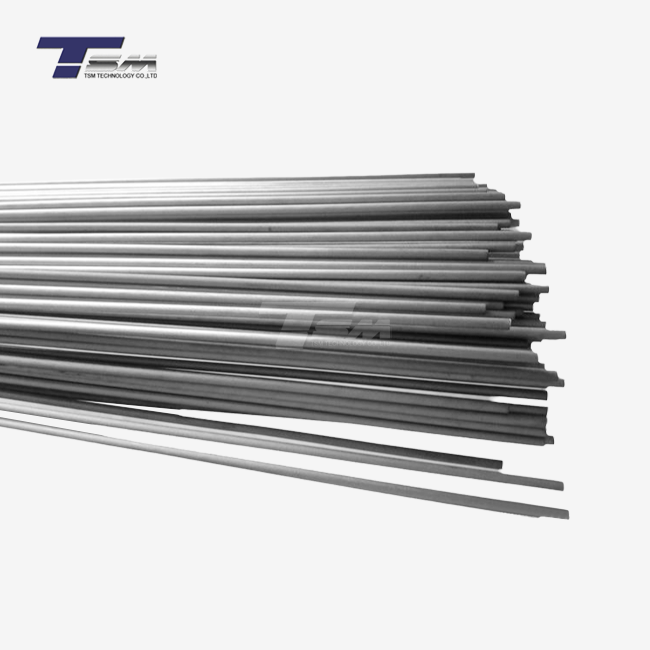

Cold rolling Monel 400 bar offers several advantages over hot rolling or other forming methods. The process significantly increases the material's yield strength and hardness, often doubling these properties compared to the annealed state. This enhancement in mechanical properties is achieved without compromising the alloy's excellent corrosion resistance.

The cold rolling process also imparts a superior surface finish to the Monel bar, reducing the need for additional machining or polishing. The tight dimensional tolerances achieved through cold rolling make it ideal for precision engineering applications. Moreover, the work hardening induced by cold rolling can improve the fatigue resistance of Monel 400, extending the lifespan of components subjected to cyclic loading.

The Cold Rolling Process for Monel 400 Bar

Preparation of Monel 400 for Cold Rolling

Before the cold rolling process begins, the Monel 400 round bar undergoes thorough preparation. This typically involves annealing the material to soften it and remove any residual stresses from previous manufacturing processes. The annealing temperature for Monel 400 usually ranges between 870°C and 980°C, followed by rapid cooling.

After annealing, the Monel bar is cleaned and inspected for surface defects. Any imperfections are removed through grinding or machining to ensure a uniform starting material. The bar is then coated with a lubricant to reduce friction during the rolling process and prevent surface damage.

Cold Rolling Equipment and Setup

The cold rolling of Monel 400 bar is typically performed on a multi-stand rolling mill. This equipment consists of a series of hardened steel rolls arranged in pairs. The gap between these rolls can be precisely adjusted to control the reduction in thickness with each pass.

Modern cold rolling mills for Monel bar production are often computer-controlled, allowing for precise control of rolling speed, pressure, and inter-stand tension. This level of control ensures consistency in the final product and enables the production of Monel 400 round bar with extremely tight tolerances.

Step-by-Step Cold Rolling Process

The cold rolling process for Monel 400 bar typically involves multiple passes through the rolling mill. In each pass, the Monel bar is compressed between the rolls, reducing its thickness and increasing its length. The amount of reduction per pass is carefully controlled to avoid cracking or excessive work hardening of the material.

Between passes, the Monel bar may be rotated 90 degrees to ensure uniform deformation and prevent the development of directional properties. The number of passes and the total reduction in thickness depend on the desired final properties of the Monel 400 bar.

After the final pass, the cold-rolled Monel bar may undergo stress relief annealing to reduce internal stresses induced by the cold working process. This heat treatment is performed at lower temperatures than the initial annealing, typically between 425°C and 650°C, to preserve the strength gained through cold rolling while improving ductility.

Quality Control and Post-Processing of Cold-Rolled Monel 400 Bar

Inspection and Testing Procedures

Rigorous quality control measures are essential to ensure the cold-rolled Monel 400 bar meets industry standards and customer specifications. Dimensional inspections are performed using precision measuring instruments to verify that the bar's diameter, straightness, and surface finish are within the required tolerances.

Non-destructive testing methods, such as ultrasonic testing and eddy current inspection, are employed to detect any internal defects or surface imperfections in the Monel bar. Mechanical property testing, including tensile tests and hardness measurements, is conducted to verify that the cold-rolled Monel 400 round bar meets the specified strength and ductility requirements.

Surface Finishing Techniques

While cold rolling significantly improves the surface finish of Monel 400 bar, additional surface treatments may be applied to meet specific requirements for Monel round bar. Polishing can be used to achieve a mirror-like finish, enhancing the bar's corrosion resistance and aesthetic appeal. For applications requiring maximum corrosion protection, electropolishing may be employed to remove a thin layer of material, leaving an ultra-smooth, passive surface on the Monel bar.

In some cases, the cold-rolled Monel 400 bar may be subjected to shot peening or other surface hardening treatments to further enhance its fatigue resistance and wear properties. These processes introduce compressive stresses in the surface layer, which can significantly improve the component's performance in demanding applications.

Packaging and Storage Considerations

Proper packaging and storage of cold-rolled Monel 400 bar are crucial to maintain its quality and prevent surface damage. The bars are typically wrapped in protective materials such as plastic sheeting or VCI (Volatile Corrosion Inhibitor) paper to prevent corrosion during transportation and storage.

For long-term storage, the Monel bar should be kept in a dry, temperature-controlled environment to prevent moisture accumulation and potential corrosion. Proper handling procedures, including the use of non-metallic slings or padding on lifting equipment, are essential to prevent surface damage to the cold-rolled Monel 400 round bar during movement and storage.

Conclusion

The cold rolling process of Monel 400 bar represents a critical manufacturing technique that significantly enhances the material's properties and expands its application range. By carefully controlling the rolling parameters and post-processing treatments, manufacturers can produce Monel 400 round bars with exceptional strength, dimensional accuracy, and surface quality. This advanced processing method ensures that Monel bar continues to meet the demanding requirements of various industries, from marine engineering to aerospace applications. As material science advances, the cold rolling process for Monel 400 and similar alloys will likely see further refinements, leading to even more impressive performance characteristics and broader industrial applications.

Contact Us

For more information about our high-quality Monel 400 bar products and other superior nickel alloys, please don't hesitate to contact TSM TECHNOLOGY at info@tsmnialloy.com. Our team of experts is ready to assist you in finding the perfect alloy solution for your specific needs.